ACU-RITE ENC 250SS User Manual

Page 11

Acu-Rite Companies Inc.

ENC 250™

SINGLE SECTION

9

Encoder Installation Procedure

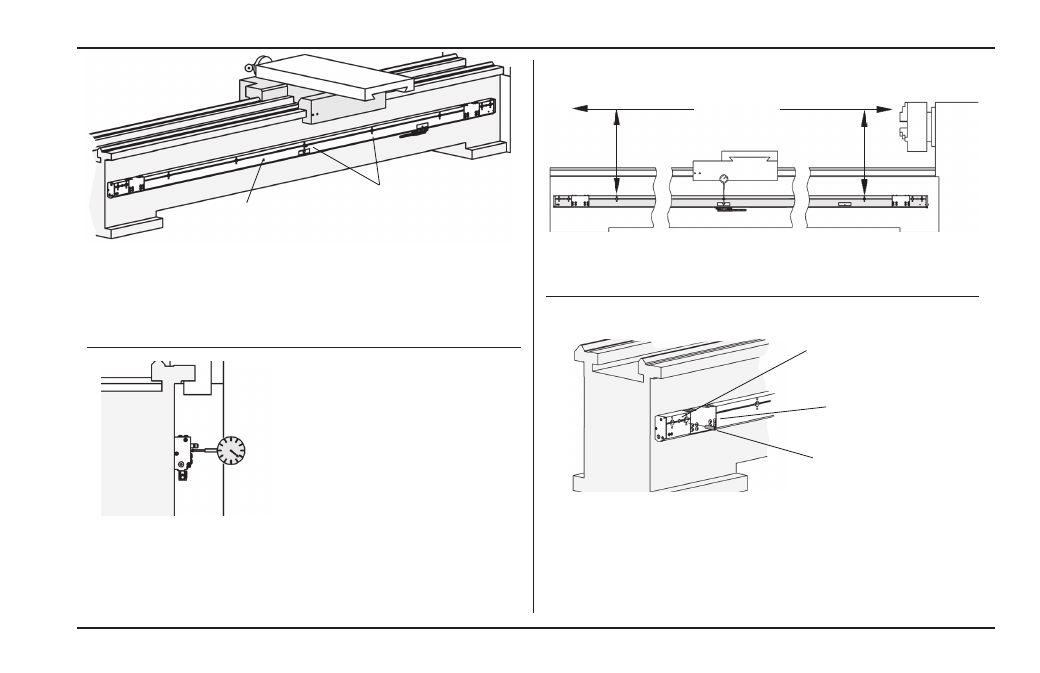

• Loosen the next two fasteners to the right of the high point.

• Move indicator to the first hole location, insert two M3 x 25mm

SHSS (leveling set screws).

• Use the leveling screws to align the face to within [.012”] .3mm

to the high point along the axis travel and secure the fastener.

Example:

high point

Loosen next two

fasteners

• Move indicator to the next hole location, and loosen the next

fastener to the right of that fastener. Align this location.

• Repeat the previous steps to align the face at each fastener.

• Return to the high point, and use the same procedure working to

the left end.

Run indicator along the front

face to align scale case to within

[.012”] .3mm to the axis travel

• Recheck the scale case top alignment, by starting at the

center hole location, and adjust as necessary.

Axis Travel

Align to within [.012”] .3mm TIR to the axis

travel measuring over each hole location

Dowel pin anchoring ...

• Drill a [.302”] 7.7mm diameter hole through the dowel pin hole

locations at each end of the scale case [.375] 9.5mm deep.

• Use a [.312] 8mm reamer to provide a press fit.

• Insert the dowel pins at each end, with the threaded holes facing

outward.

• Loosen the BHCS (16) on each expansion cover, approximately

[1/8”] 3mm turn each.

[5/16”] 8mm Dowel

Pin (2)

Scale case holes are

undersized to insure

accurate centering.

BHCS (16) on each

expansion cover