ACU-RITE SENC 150 User Manual

Page 16

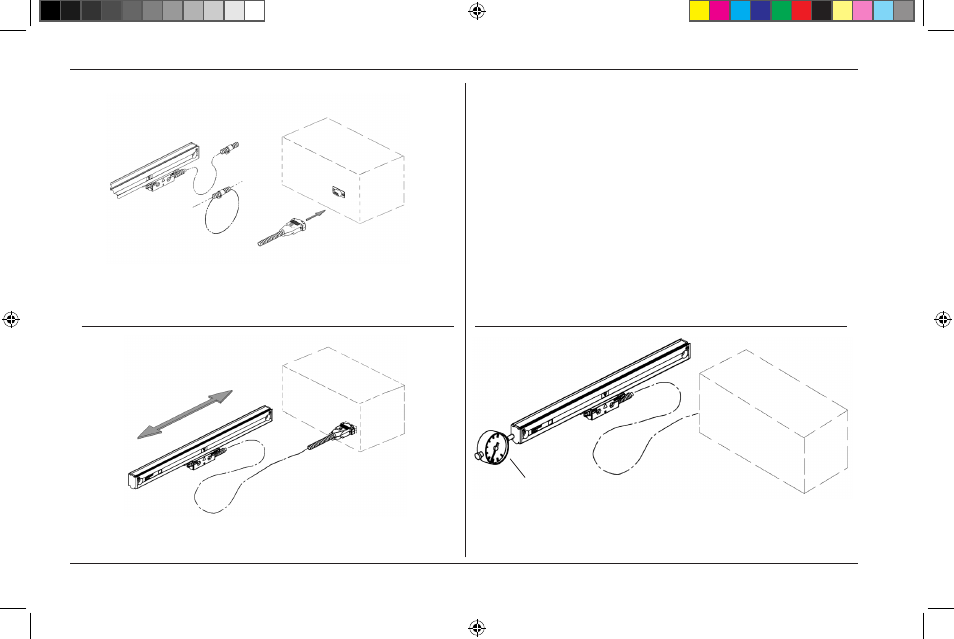

• Route the cables with slack loops to allow for axis motion.

• Secure excess cable by fastening with clips or ties.

• Attach the linear encoder connectors to the readout.

• Move the axis and compare the display to the movement.

• Move the axis 20mm (.79”) to check reference mark operation.

• Zero the display and indicator.

• Move axis to the end of it’s travel return to dial zero.

• Readout should read zero ± 1 count.

Checking Your Installation

SENC 150

Place dial indicator at the end of the moving

component (scale assembly or reading head).

Repeatability Test

Readout

Counting Test

Connecting

Counting Test:

• Configure the readout’s encoder and display resolution (see

manual).

• Move the axis and compare the display to the movement.

• Configure readout for sensing reference marks.

• Move each axis a minimum of 20mm (axis display should zero).

Repeatability Test:

• Locate an indicator on one end of the encoder and zero the

readout and indicator.

• Move the axis through the full travel and return to dial zero.

• Readout should read zero ± 1 count.

These steps will confirm proper operation of your installation.

The Counting Test confirms proper electrical operation. The

Repeatability Test checks the installation integrity.

Secure excess

cable

Provide slack

loops

Attach connector

14

ACU-RITE

®

516291-21_Ve00_SENC_150.indd 16

10/22/2009 10:00:46 AM