ACU-RITE SENC 150 User Manual

Page 11

SENC 150

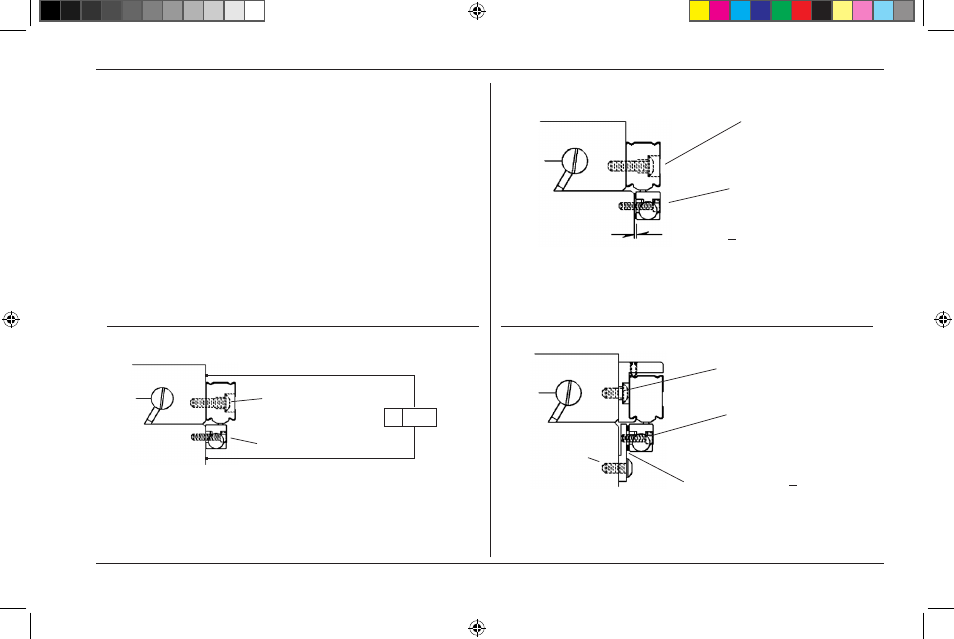

Typical Mounting (s)

9

ACU-RITE

®

1/4-20 x 1” BHCS

with encoder washer

A variety of mounting conditions can be accommodated.

• The machine configuration determines the brackets required to

install the linear encoder.

• Three typical mounting conditions are shown; flush, offset, and

backup spar (as shown previously on page 4).

• The 8-32 SHCS fastener lengths shown on this page are

supplied with the encoder hardware.

• The 8-32 SHCS for mounting the reading head is a standard low

head style fastener.

• Mounting surfaces are offset.

• Installation without backup spar.

• Use leveling screws in place of spacers or shims.

• Mounting surfaces are flush within .005”.

• The reading head leveling screws are not required.

• Flush or offset mounting surfaces with a backup spar.

• Bracket used to reduce head to mounting surface gap.

• Use reading head leveling set screws.

Backup spar with bracket

Offset surfaces

1/4-20 x 1” BHCS

and encoder washer

8-32 x 3/4” SHCS

Flush surfaces

ll .005

8-32 x 3/4” SHCS

Space of < .18” use reading

head leveling set screws.

1/4-20 x 1/2” BHCS

and spar washer

8-32 x 5/8” SHCS

(trim if necessary)

1/4-20 x 1/2” BHCS

and washer

A space >.18”, use a spacer

or bracket (shown); <.18” use

leveling set screws.

516291-21_Ve00_SENC_150.indd 11

10/22/2009 10:00:42 AM