Machine inspection, Specifications – RIDGID Power-Spin User Manual

Page 6

POWER-SPIN® Drain Cleaner

4

Cable Size

Recommended Line

Size & Reach

Line Size

Reach

1

/

4

" (6 mm) Cable Up to 1

1

/

2

"

(40 mm)

25' (7,6 m)

Specifications

Drum Capacity......... 25' (7,6 m) of

1

/

4

"

(6 mm) Diameter

MAXCORE Cable

Drum Speed................ Maximum 500 RPM

Weight.......................... 4.7 lbs. (2,1 kg)

NOTICE

This machine is made to clean

drains. If properly used it will not damage a

drain that is in good condition and properly

designed, constructed and maintained. If the

drain is in poor condition, or has not been

properly designed, constructed and main-

tained, the drain cleaning process may not

be effective or could cause damage to the

drain. The best way to determine the condi-

tion of a drain before cleaning is through vi-

sual inspection with a camera. Improper use

of this drain cleaner can damage the drain

cleaner and the drain. This machine may not

clear all blockages.

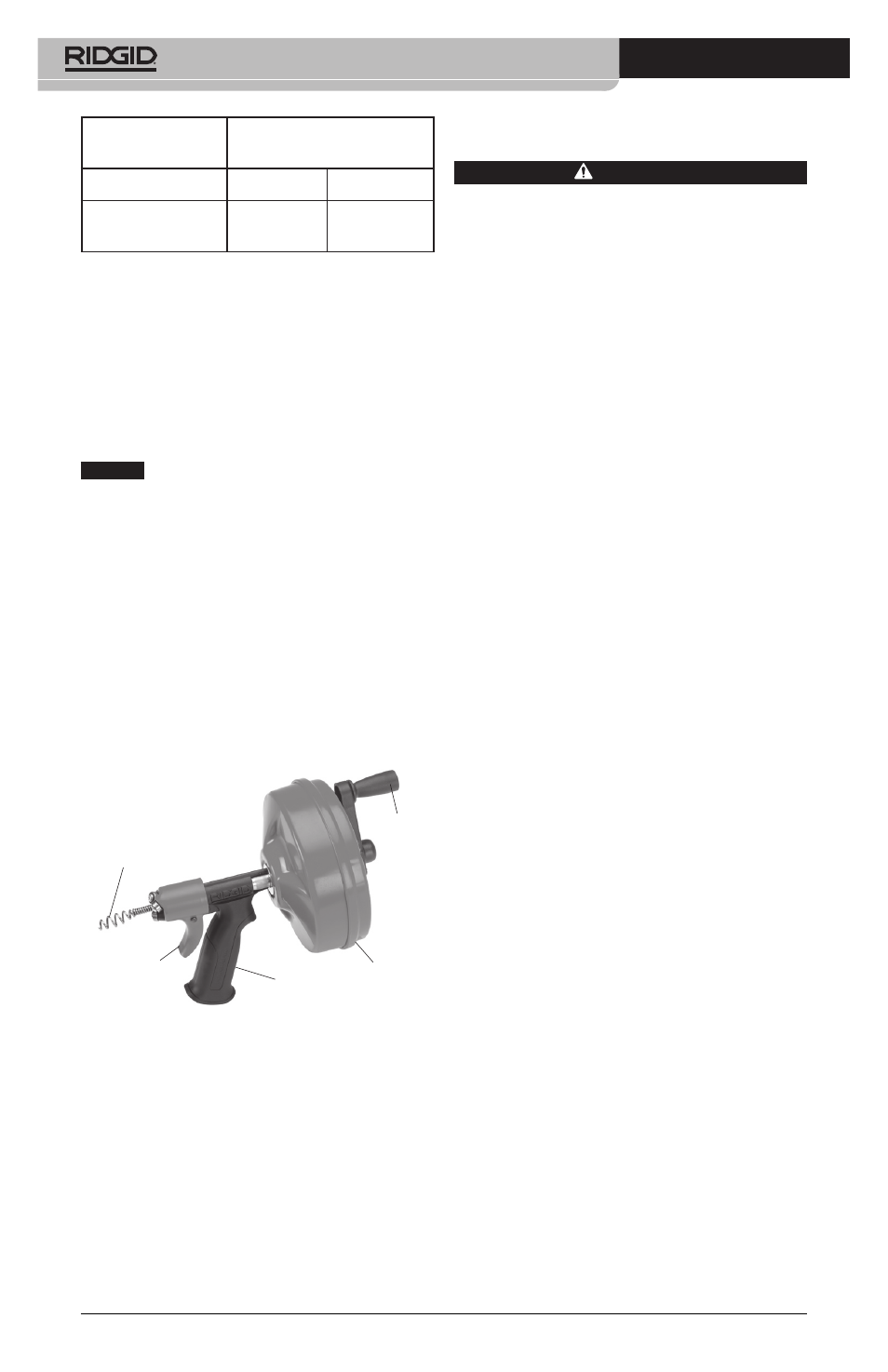

Cable End

Crank

Trigger

Handle

Drum

Figure 1 – Power-Spin

Machine Inspection

WARNING

Before each use, inspect your drain clean-

ing machine and correct any problems to

reduce the risk of serious injury from elec-

tric shock, twisted or broken cables, chemi-

cal burns, infections and other causes and

prevent drain cleaner damage.

1. Clean any oil, grease or dirt from all

equipment, including handles and con-

trols. This aids inspection and helps

prevent the machine or control from

slipping from your grip. Clean any debris

from the cable and drum.

2. Inspect the drain cleaner for the follow-

ing items:

• Proper assembly and completeness

• Broken, worn, missing, misaligned or

binding parts

• Smooth and free movement of the

trigger and drum

• Presence and readability of the warn-

ing label (see Figure 2.)

If any problems are found, do not use

the drain cleaner until the problems

have been repaired.

3. Inspect cable for wear and damage –

Look for:

• Obvious flats worn into the outside of

the cable (cable is made from round

wire and profile should be round).

• Multiple or excessively large kinks

(slight kinks up to 15 degrees can be

straightened).

• Space between the cables indicat-

ing the cable has been deformed by

stretch ing, kinking or run in REVERSE.

• Excessive corrosion from storing wet

or exposure to drain chemicals.

All of these forms of wear and damage

weaken the cable and make cable twist-

ing, kinking or breaking more likely dur-

ing use. Replace worn and damaged

cable before using drain cleaner.

4. If using the Power-Spin Drain Cleaner

with a Battery Power Drill, inspect the

drill per it’s instructions. Make sure that

the drill is in good operating condition

and the switch controls the drill opera-

tion. Confirm that the drill turns at less

than 500 rpm.