Troubleshooting, Predator, Flash codes – York PREDATOR BP120 User Manual

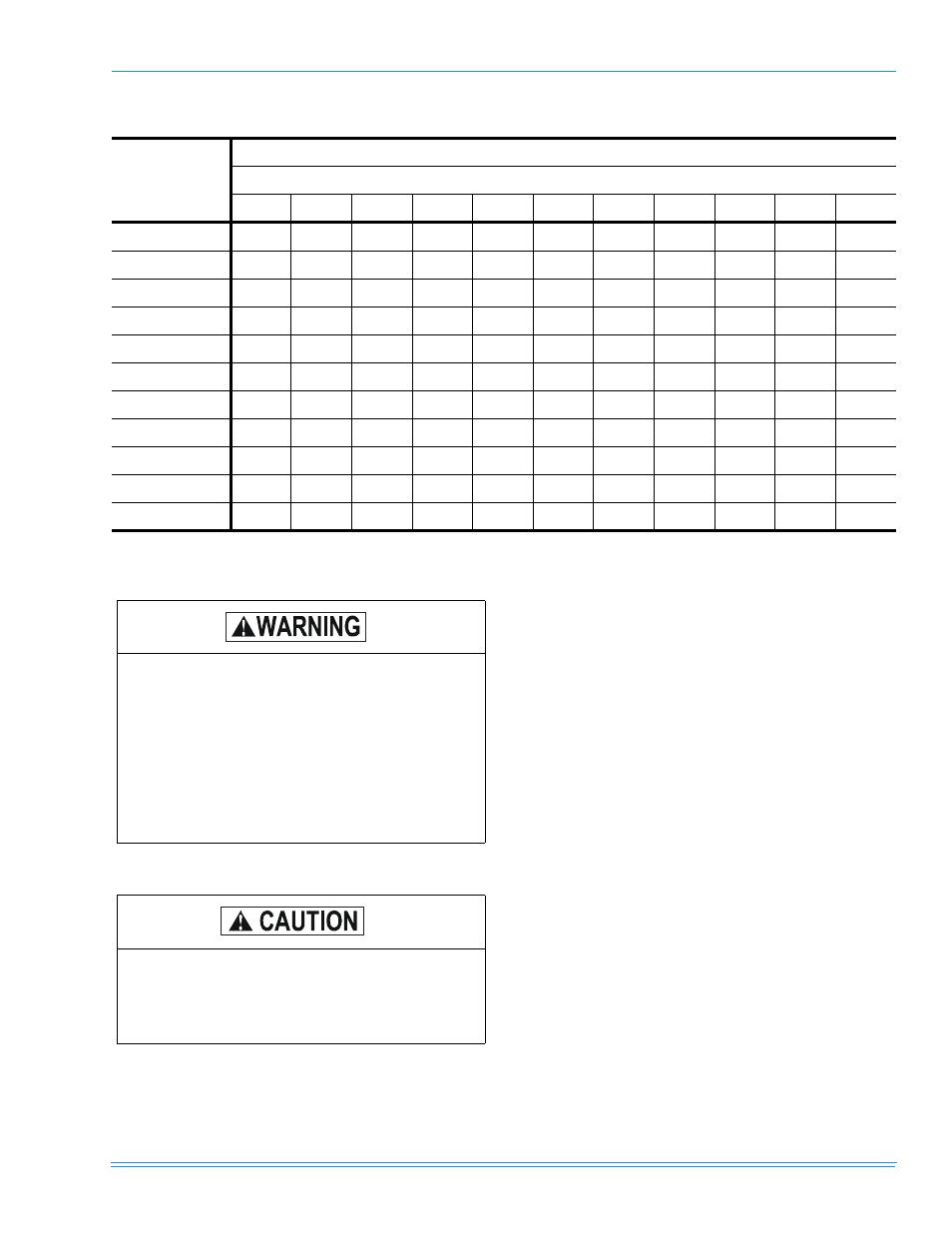

Page 39: Table 37: cooling superheat 10 ton

66307-YIM-B-0606

Unitary Products Group

39

TROUBLESHOOTING

PREDATOR

®

FLASH CODES

Various flash codes are utilized by the unit control board

(UCB) to aid in troubleshooting. Flash codes are

distinguished by the short on and off cycle used

(approximately 200ms on and 200ms off). To show normal

operation, the control board flashes a 1 second on, 1 second

off "heartbeat" during normal operation. This is to verify that

the UCB is functioning correctly. Do not confuse this with an

error flash code. To prevent confusion, a 1-flash, flash code

is not used.

Alarm condition codes are flashed on the UCB lower left Red

LED, See Figure 23. While the alarm code is being flashed, it

will also be shown by the other LEDs: lit continuously while

the alarm is being flashed. The total of the continuously lit

LEDs equates to the number of flashes, and is shown in the

table. Pressing and releasing the LAST ERROR button on

the UCB can check the alarm history. The UCB will cycle

through the last five (5) alarms, most recent to oldest,

separating each alarm flash code by approximately 2

seconds. In all cases, a flashing Green LED will be used to

indicate non-alarm condition.

In some cases, it may be necessary to "zero" the ASCD for

the compressors in order to perform troubleshooting. To reset

all ASCDs for one cycle, press and release the UCB TEST/

RESET button once.

Flash codes that do and do not represent alarms are listed in

Table 38.

TABLE 37: COOLING SUPERHEAT 10 TON

OUTDOOR

TEMP °F

SUCTION SUPERHEAT °F

INDOOR WB TEMP °F

55 57 59 61 63 65 67 69 71 73 75

65

41.0

40.9

40.7

40.6

40.5

40.4

40.3

40.1

40.0

39.9

39.8

70

38.3

38.2

38.2

38.2

38.1

38.1

38.1

38.0

38.0

38.0

37.9

75

35.6

35.6

35.7

35.7

35.8

35.8

35.9

35.9

36.0

36.0

36.1

80

25.7

26.7

27.6

28.5

29.5

30.4

31.3

32.3

33.2

34.1

35.1

85

15.9

17.7

19.5

21.3

23.2

25.0

26.8

28.6

30.4

32.3

34.1

90

14.4

16.1

17.8

19.5

21.1

22.8

24.5

26.2

27.9

29.5

31.2

95

13.0

14.5

16.0

17.6

19.1

20.7

22.2

23.7

25.3

26.8

28.4

100

9.8

11.4

13.0

14.5

16.1

17.7

19.3

20.9

22.5

24.0

25.6

105

6.6

8.2

9.9

11.5

13.1

14.8

16.4

18.0

19.6

21.3

22.9

110

4.6

5.9

7.2

8.5

9.8

11.1

12.4

13.7

14.9

16.2

17.5

115

2.5

3.5

4.5

5.4

6.4

7.4

8.3

9.3

10.3

11.2

12.2

Troubleshooting of components may require open-

ing the electrical control box with the power con-

nected to the unit. Use extreme care when

working with live circuits! Check the unit name-

plate for the correct line voltage and set the voltme-

ter to the correct range before making any

connections with line terminals.

When not necessary, shut off all electric power to the

unit prior to any of the following maintenance proce-

dures so as to prevent personal injury.

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dan-

gerous operation which could cause injury to person

and/or damage unit components. Verify proper oper-

ation after servicing.