Start-up – York PREDATOR BP120 User Manual

Page 36

66307-YIM-B-0606

36

Unitary Products Group

at the position of the defrost thermostats. This action is

repeated until, at the completion of a run time cycle, one of

the defrost thermostats is found to be closed and the DC

enters defrost mode.

When the DC enters the defrost mode, it’s on-board defrost

relay is powered. This energizes both reversing valves, de-

energizes both condenser fan motors and energizes the

unit’s optional electric heater. The DC remains in defrost

mode until either of the following two conditions is met:

1.

Both of the liquid line thermostats are open. Each is set

to open at 55 degrees (+/- 3).

2.

The maximum defrost run time of 10 minutes is met.

The DC also contains a set of test pins. Placing a jumper

across these pins will result in the following actions:

•

If the ASCD timer is active, it is now by-passed, allowing

the compressor to run.

•

If the DC is in a lockout condition, the lockout is reset.

•

If the compressor is running, the DC is forced into defrost

mode. The control will remain in defrost mode for as long

as the jumper is in place. When the jumper is removed,

the control will terminate the defrost mode in the normal

manor as described above.

NOTE:

The DC has two flashing codes which are only initi-

ated if the two pressure switch terminals are open.

As used in the Predator

®

, there is a jumper across

the pressure switch terminals. Therefore the field

should never experience a DC lockout mode unless

that jumper is removed or broken.

ELECTRIC HEAT OPERATION ERRORS

TEMPERATURE LIMIT

If the UCB senses zero volts from the high temperature limit,

the indoor blower motor is immediately energized.

This limit is monitored regardless of unit operation status, i.e.

the limit is monitored at all times.

If the temperature limit opens three times within one hour, it

will lock-on the indoor blower motor and a flash code is initi-

ated (See Table 38).

SAFETY CONTROLS

The UCB monitors the temperature limit switch of electric

heat units.

The control circuit includes the following safety controls:

LIMIT SWITCH (LS)

This control is located inside the heater compartment and is

set to open at the temperature indicated in the Electric Heat

Limit Setting Table 33. It resets automatically. The limit switch

operates when a high temperature condition, caused by inad-

equate supply air flow occurs, thus shutting down the heater

and energizing the blower.

FLASH CODES

The UCB will initiate a flash code associated with errors

within the system. Refer to UNIT CONTROL BOARD FLASH

CODES Table 38.

RESET

Remove the call for heating by lowering the thermostat set-

ting lower than the conditioned space temperature.This

resets any flash codes.

ELECTRIC HEAT ANTICIPATOR SETPOINTS

It is important that the anticipator setpoint be correct. Too

high of a setting will result in longer heat cycles and a greater

temperature swing in the conditioned space. Reducing the

value below the correct setpoint will give shorter “ON” cycles

and may result in the lowering of the temperature within the

conditioned space. Refer to Table 34 for the required electric

heat anticipator setting.

START-UP

PRESTART CHECK LIST

After installation has been completed:

1.

Check the electrical supply voltage being supplied. Be

sure that it is the same as listed on the unit nameplate.

2.

Set the room thermostat to the off position.

3.

Turn unit electrical power on.

4.

Set the room thermostat fan switch to on.

5.

Check indoor blower rotation.

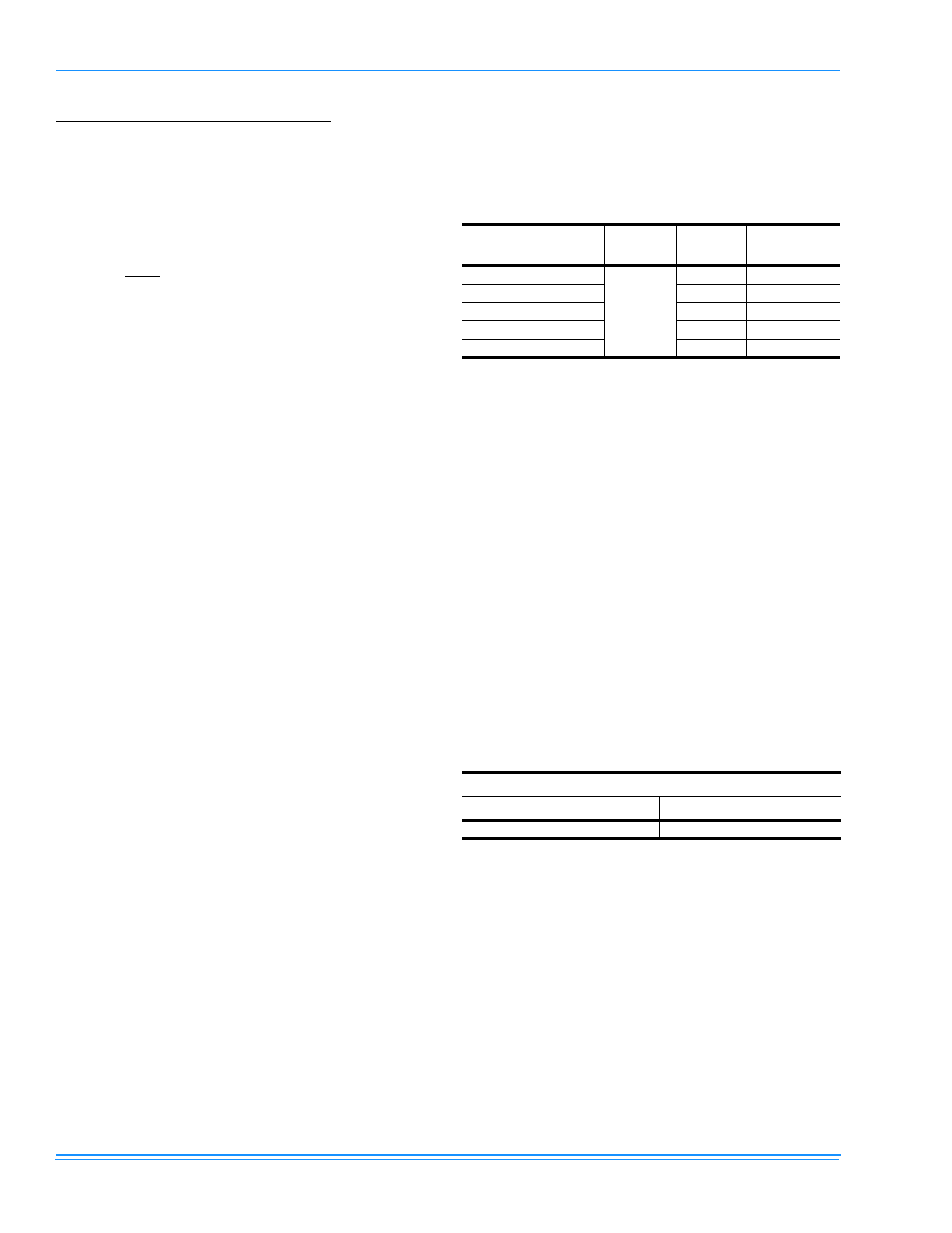

TABLE 33: ELECTRIC HEAT LIMIT SETTING

UNIT (TONS

VOLTAGE

HEATER

kW

LIMIT SWITCH

OPENS °F

7.5

380/415

9

150

7.5,10

18

150

7.5,10

24

150

7.5,10

34

150

10

54

140

TABLE 34: HEAT PUMP ANTICIPATOR SETPOINTS

SETTING, AMPS

W1

W2

0.13

0.1