York PREDATOR BP120 User Manual

Page 22

66307-YIM-B-0606

22

Unitary Products Group

PHASING

Predator

®

units are properly phased at the factory. Check for

proper compressor rotation. If the blower or compressors

rotate in the wrong direction at start-up, the electrical connec-

tion to the unit is misphased. Change the phasing of the field

line connection at the field supplied disconnect to obtain

proper rotation. (Scroll compressors operate in only one

direction. If the scroll is drawing low amperage, has similar

suction and discharge pressures, or producing a high noise

level, the scroll is misphased). Units with scroll compressors

have a phase monitor as standard equipment. This phase

monitor will prevent unit operation under misphased condi-

tions by breaking the 24 volt power.

BLOWER ROTATION

Check for proper supply air blower rotation. If the blower is

rotating backwards, the line voltage at the unit point of power

connection is misphased (See ‘PHASING’).

BELT TENSION

The tension on the belt should be adjusted as shown in

Figure 22.

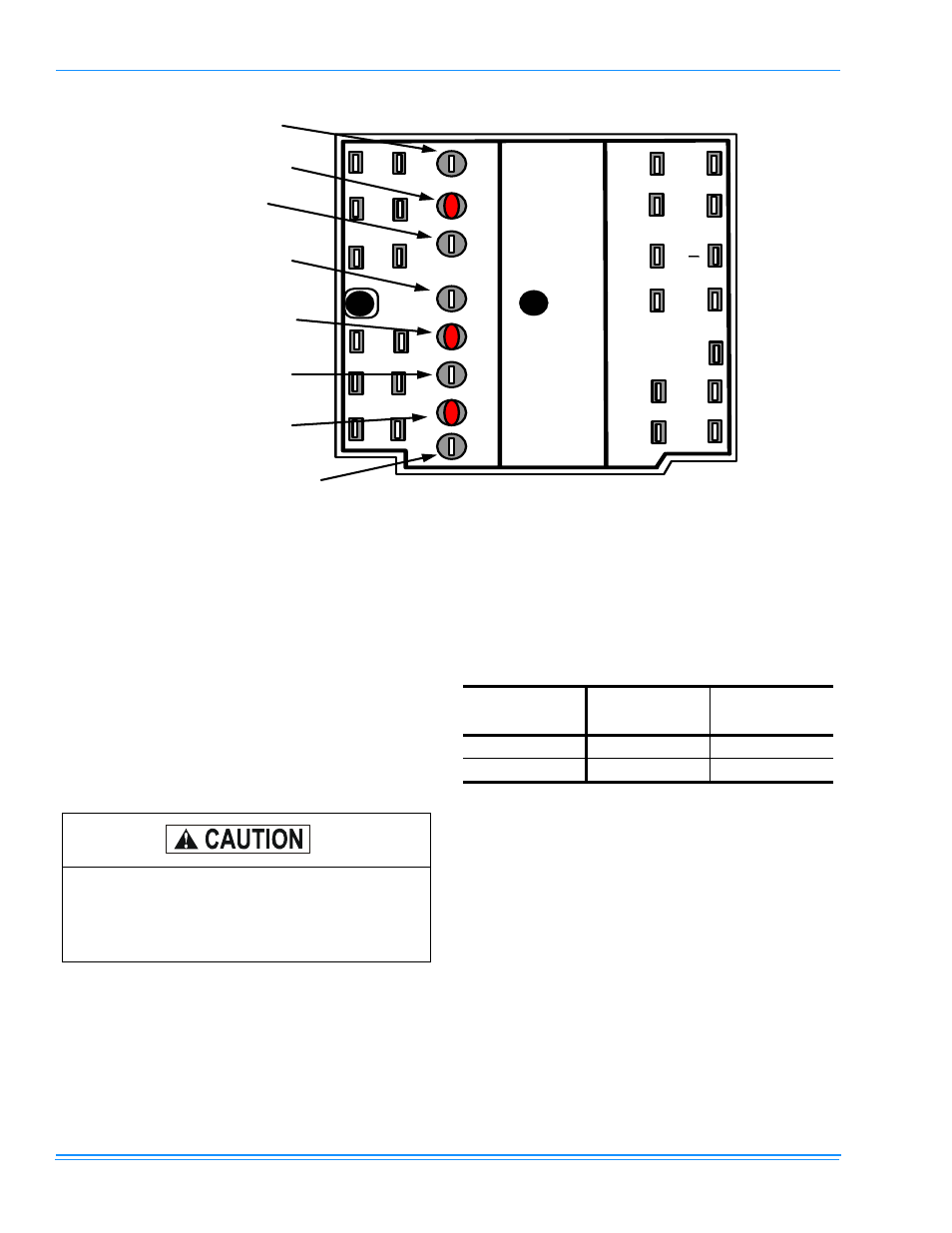

FIGURE 21 - HONEYWELL ECONOMIZER CONTROL W7212

N1

N

P1

P

EXH

Set

EXH

Min

Pos

IAQ

Max

IAQ

IAQ

Min

Free

Cool

T

T1

AQ1

AQ

SO+

SO

SR+

SR

A

B

C

D

TR

TR1

24

Vac

HOT

24

Vac

COM

EF

EF1

2

3

4

5

1

+

Exhaust Air

Adjustment

Screw

Exhaust Air LED

Damper Min.

Position

Screw

Indoor Air Quality

Max. Adjustment

Screw

Indoor Air Quality

LED

Indoor Air Quality

Min. Adjustment

Screw

Free Cooling LED

Economizer Enthalpy

Set Point Adjustment

Screw

Scroll compressors require proper rotation to oper-

ate correctly. Units are properly phased at the fac-

tory. Do not change the internal wiring to make the

blower condenser fans, or compressor rotate cor-

rectly.

TABLE 12: SUPPLY AIR LIMITATIONS

Unit Size

Minimum CFM

(m

3

/sec.)

Maximum CFM

(m

3

/sec.)

090

2250 (1)

3750 (1.7)

120

3000 (1.4)

5000 (2.3)