Prepare boiler — placement & setup, Inspect orifices and burners, Orifice replacement procedure – Weil-McLain GOLD CGS-4E User Manual

Page 12

Part number 550-110-282/1108

12

GOLD

CGs-4E Gas-Fired Water Boiler — Boiler Manual

Place boiler/crate near

position

1. Leave boiler in crate and on pallet until installation

site is ready.

2. Move entire crate and pallet next to selected loca-

tion.

3. Remove crate.

4. Remove boiler from pallet.

Do not drop boiler or bump jacket

on floor or pallet. Damage to boiler

can result.

a. Tilt left side of boiler up and place a board

under left legs.

b. Tilt boiler the other way and place a board

under right legs.

c. Slide boiler backward off pallet and into posi-

tion.

5. Check level.

a. Shim legs, if necessary.

b. Do not alter legs.

Prepare boiler — placement & setup

2a

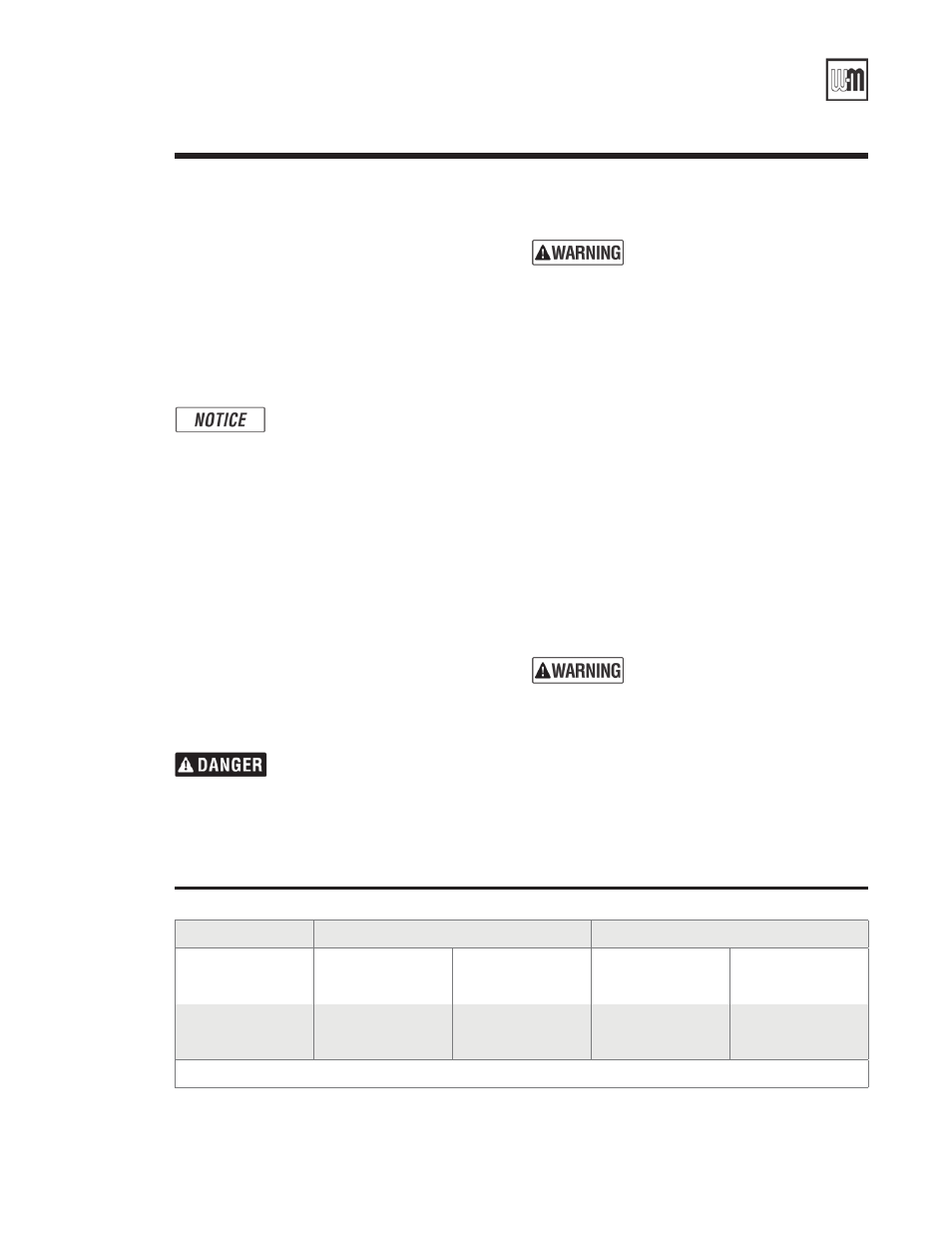

Table 2 Manifold orifice sizing

Location

Natural gas

Propane gas

U. S.

0-2,000 ft

over 2,000 ft

0-2,000 ft

over 2,000 ft

2.55 mm

(Note 1)

1.60 mm

(Note 1)

Canada

0-2,000 ft

2,000-4,500

0-2,000 ft

2,000-4,500

2.55 mm

#41

1.60 mm

1.45 mm

Note 1:

For elevations above 2,000 feet, contact your local Weil-McLain sales office for details.

Inspect orifices and burners

1. Remove front jacket door. Remove inlet air box top

panel (see

Figure 27

, item

13

, page 56).

2. Check for correctly-sized manifold orifices. See

Table 2

for sizing. (The orifice size is stamped on

the orifice spud barrel.)

Correctly-sized manifold orifices

must be used. Failure to do so will

result in severe personal injury,

death or substantial property dam-

age.

3. Reinstall inlet air box top panel.

Orifice replacement procedure

(when required)

1. Remove the screws securing the inlet air box top

panel.

2. Remove inlet air box top panel and inspect the fiber

gasket. Verify the gasket is in good condition and can

seal around the complete perimeter of the air box.

Replace the gasket if necessary.

3. Using a

7

/

16

” open-end wrench, remove the burner

orifices from the manifold.

4. Apply a small amount of pipe dope to each of the

new orifices and install in the manifold using a

7

/

16

”

open-end wrench. Make sure the orifices are aligned

correctly, not cross-threaded in the manifold tap-

pings.

Use only pipe dope compatible with

propane gas, even if boiler is to be

operated on natural gas. Failure to

comply could result in severe per-

sonal injury, death or substantial

property damage.

5. Carefully replace the inlet air box top panel, making

sure the gasket is in place will seal all around the

perimeter.

6. Follow the check-out procedure, Section

8

page 31,

to assure the boiler is now operating properly after

orifices are replaced.

Inlet air box top panel must be in

position during boiler operation.

Failure to do so could result in

severe personal injury, death or

substantial property damage.