Wayne-Dalton 8850 User Manual

Page 15

15

Please Do Not Return This Product To The Store. Contact your local Wayne-Dalton dealer. To find your local Wayne-Dalton dealer, refer to your

local yellow pages/business listings or go to the

Find a Dealer section online at www.wayne-dalton.com

Tools Needed:

Tools Needed:

iNST

alla

Tio

N

15

iNST

alla

Tio

N

13

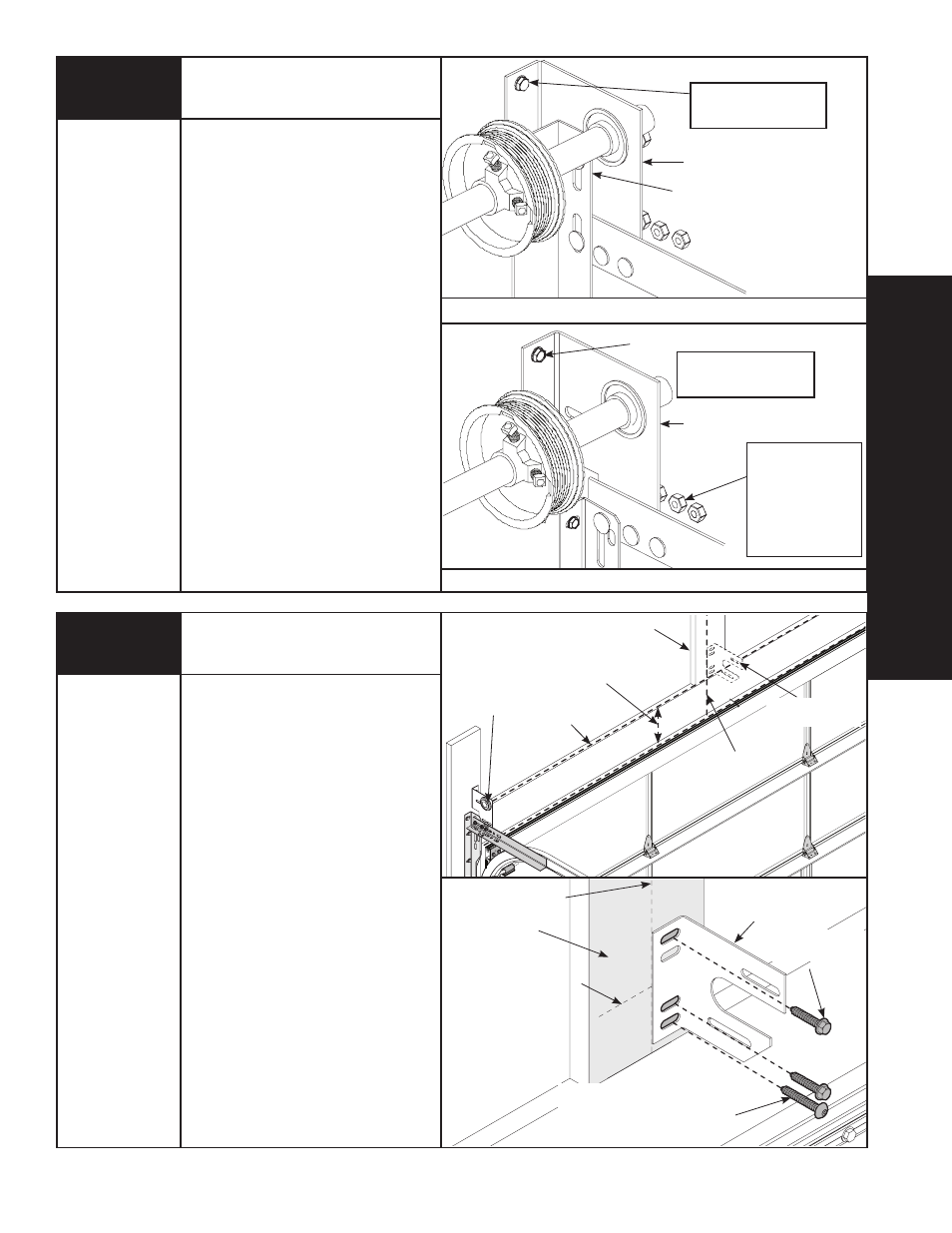

Torsion end bearing brackets

imPoRTaNT: RIGhT AND LEfT hAND IS

ALWAYS DETERMINED fROM INSIDE ThE

GARAGE LOOKING OUT.

Attach the EBf’s (end bearing fixtures/

brackets) to the horizontal reinforcing

angles using (3) 3/8” - 18 x 3/4” truss bolts

and nuts, as shown

.

Once the bracket is secured to the

horizontal angle, secure the top of the

end bearing bracket to the jamb using

(2) 5/16” x 1-5/8” hex head lag screws.

Repeat for other side.

Power Drill

7/16” Socket

Driver

9/16” Socket

Ratchet Wrench

9/16” Wrench

(3) 3/8” - 18 X 3/4”

TRUSS BOLTS AND

NUTS.

(2) fOR SECURING END

BRACKET

(1) fOR SECURING

hORIzONTAL ANGLE TO

fLAG ANGLE

END BEARING BRACKET

5/16” X 1-5/8” hEX hEAD LAG SCREW

ThIS ILLUSTRATION ShOWS

12” RADIUS TRACK W/LAG

BOLT TO WOOD.

CUT Off 3” Of WALL

ANGLE , 12” RADIUS

APPLICATIONS ONLY

END BEARING BRACKET

CONTINUOUS WALL ANGLE ATTAChED TO END BRACKET.

BRACKET MOUNT TRACK ATTAChED TO END BRACKET.

14

center bearing bracket

Power Drill

7/16” Socket

Driver

Level

Tape Measure

Pencil

1/4” Torx Bit

Measure to locate the center of the door

and mark a vertical pencil line on the

mounting surface above the door, to

indicate the center line of the door. Then,

measure from the center of the bearing, in

one of the end bearing brackets, DOWN to

the top of the door. Using that dimension,

measure UP from the top of the door

and mark a horizontal pencil line on the

mounting surface, intersecting the vertical

pencil line. Now align the edge of the

center bearing bracket along the vertical

pencil line on the mounting surface. Center

the bearing bracket on the horizontal

line. This will ensure the torsion tube is

level between the center and end bearing

brackets. Attach the center bearing bracket,

in this location, to the mounting surface,

using (2) 5/16” x 1-5/8” lag screws and

(1) 5/16” x 1-5/8” tamper-resistant lag

screw.

imPoRTaNT: USE ThE 5/16” X 1-5/8”

TAMPER-RESISTANT LAG SCREW ONLY

If MOUNTING SURfACE MOUNTED OVER

MASONRY. TAMPER-RESISTANT LAG

SCREW MUST BE ATTAChED ThROUGh ThE

BOTTOM hOLE Of ThE CENTER BEARING

BRACKET.

VERTICAL LINE

MOUNTING SURfACE

EqUAL

DISTANCE

CENTER Of

END BEARING

BRACKET

hORIzONTAL

LINE

CENTER BEARING

BRACKET

CENTER

BEARING

BRACKET

(2) 5/16” X 1-5/8”

LAG SCREWS

MOUNTING

SURfACE

hORIzONTAL LINE

VERTICAL

LINE

(1) 5/16” X 1-5/8”

TAMPER-RESISTANT LAG SCREW

OR (1) 5/16” X 1-5/8” LAG

SCREW

ThIS ILLUSTRATION ShOWS

15” RADIUS TRACK W/LAG

BOLT TO WOOD.