Wayne-Dalton 8850 User Manual

Page 10

10

Please Do Not Return This Product To The Store. Contact your local Wayne-Dalton dealer. To find your local Wayne-Dalton dealer, refer to your

local yellow pages/business listings or go to the

Find a Dealer section online at www.wayne-dalton.com

Tools Needed:

Tools Needed:

4

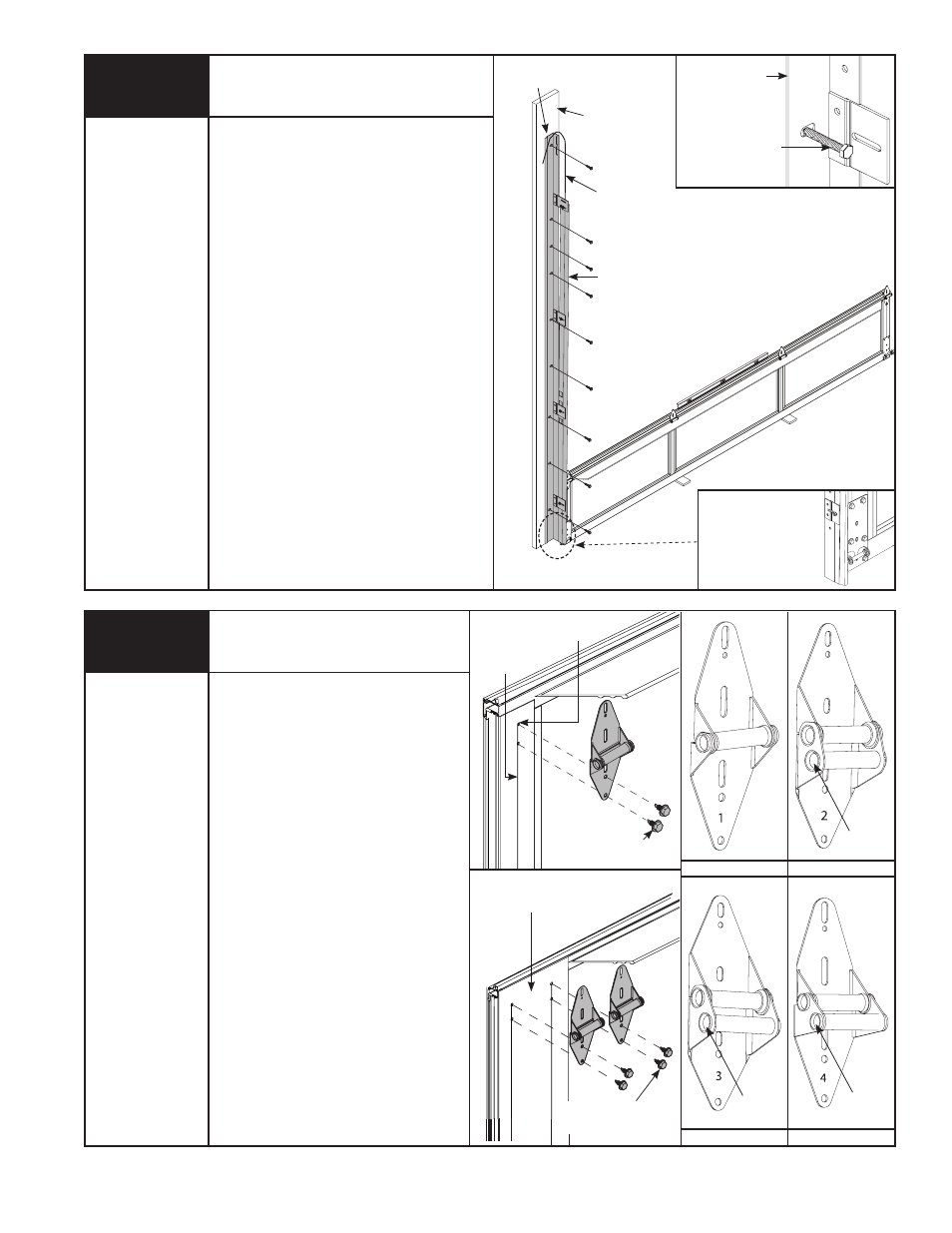

attaching continuous wall angle &

installing bottom Section

None

If your door has been installed with bracket

mount track, skip this step and continue with

the next step.

imPoRTaNT: ThE TOPS Of ThE VERTICAL

TRACKS MUST BE LEVEL fROM SIDE TO SIDE. If

ThE BOTTOM SECTION WAS ShIMMED TO LEVEL

IT, ThE VERTICAL TRACK ON ThE ShIMMED SIDE

MUST BE RAISED ThE hEIGhT Of ThE ShIM.

Position the left hand vertical track assembly

over the rollers of the bottom section. Make sure

the counterbalance cable is located between the

rollers and the door jamb. Drill 3/16” pilot holes

into the door jamb for the lag screws.

Loosely fasten vertical track assembly to the jamb

using 5/16” x 1-5/8” lag screws. Tighten the

bottom lag screw to jamb, to maintain 3/8” to 5/8”

spacing as shown between the bottom section

and vertical track. Now, tighten all remaining lag

screws. Repeat for other side.

Stack the bottom section into position by

hooking the left hand rollers into the left hand

vertical track, as shown

.

NoTe: Adjust the spacing of the vertical tracks

from 3/8” - 5/8” spacing at the bottom section

and 1-11/16” - 1-3/4” spacing at the top

section.

NoTe: hang the counterbalance cables over the

top of the continues wall angle as shown.

CONTINUOUS

WALL ANGLE

VERTICAL TRACK

5

hinges

Power Drill

7/16” Socket

Driver

#1 hINGE

#2 END hINGE

#3 END hINGE

#4 END hINGE

ROLLER

PLACEMENT

ROLLER

PLACEMENT

ROLLER

PLACEMENT

NoTe: Top sections do not require hinges.

Use the

eNDhiNge chaRT to determine

the proper endhinges for the proper section.

Install only the left hand end hinge, as the

right hand end hinge will need to be installed

when the sections are stacked. Align the

proper left hand end hinges to the proper

sections (see page 4) using the center line of

the endstile as a guide and the 2 pre-drilled

holes in the endstile to locate the placement

of the end hinge. Secure using (2) 1/4” -20 x

7/8” self drilling screws as shown. Sections

with double end stiles require 2 end hinges

per side on each section, as shown.

The end hinge sequence is dependent on

track size (2” or 3”).

2” TRack aPPlicaTioNS begin with

#1 hinges attached to the top corners of the

bottom section.

3” TRack aPPlicaTioNS begin with

#3 hinges attached to the top corners of the

bottom section.

To install center hinges on doors without

integral fins, place the center hinge over the

center stile(s), using the center line of the

stile(s) as a guide, and secure to the section

using (2) 1/4” -20 x 7/8” self drilling

1/4” -20 X 7/8” SELf-

DRILLING SCREWS

END STILE

CENTER

LINE

PRE-DRILLED

hOLES

DOUBLE

END STILE

5/16” X 1 5/8” LAG

SCREW fOR USE

ON WOOD jAMBS.

WALL ANGLE

STACK ThE SECTION

INTO POSITION, BY

hOOKING ThE LEfT

hAND ROLLER INTO

ThE VERTICAL TRACK

AND REPEATING fOR

ThE RIGhT hAND SIDE.

WOOD jAMB

1/4” -20 X 7/8” SELf

DRILLING SCREWS

COUNTERBALANCE

CABLES