Warning – Wayne-Dalton TORQUEMASTER 5120 User Manual

Page 28

28

Tools Needed:

Tools Needed:

Please Do Not Return This Product To The Store. Contact your local Wayne-Dalton dealer.

To find your Wayne-Dalton dealer; refer to your local yellow pages / business listings or go to Find a dealer area online at

www.wayne-dalton.com

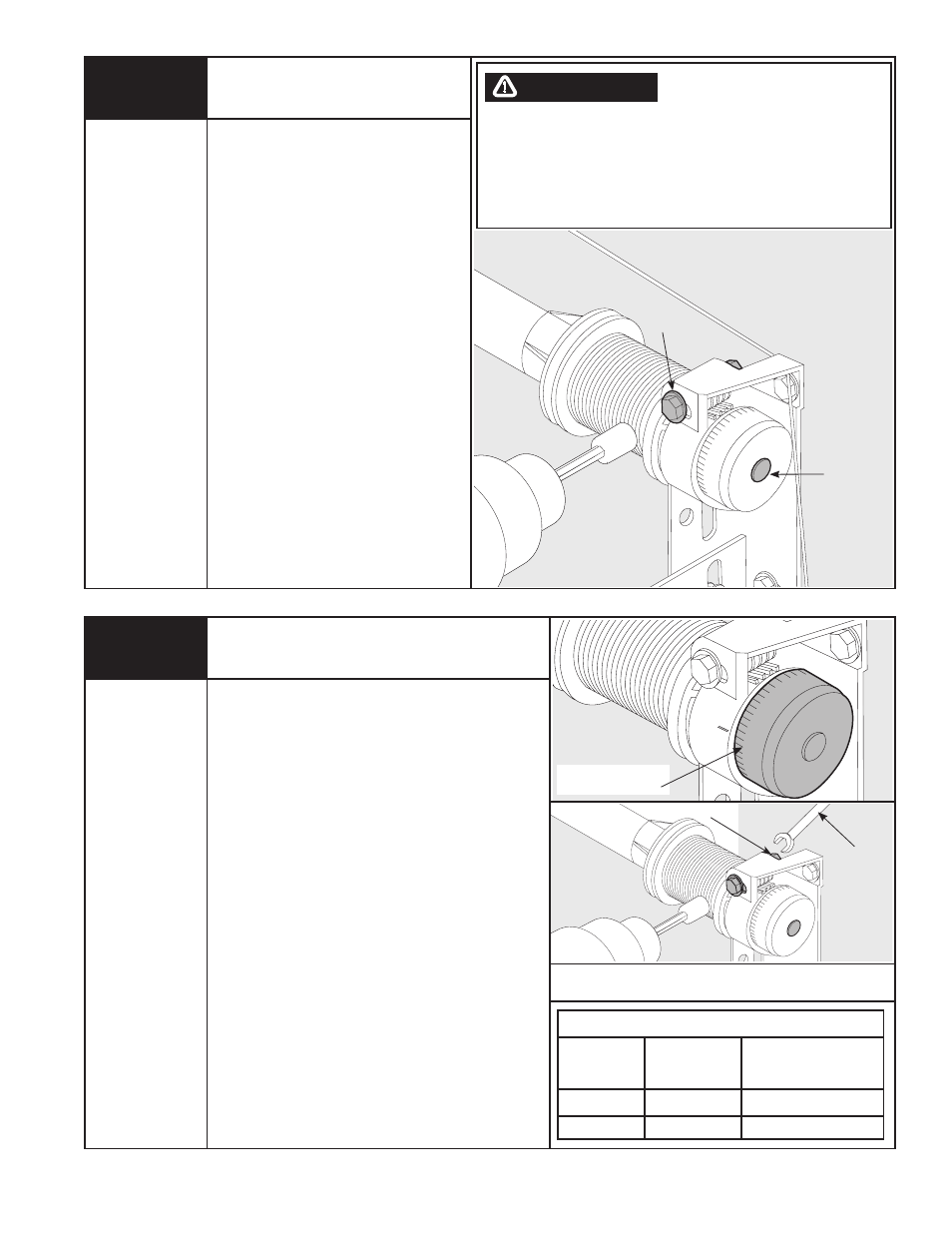

15.5

see chart in step 30 for proper spring

tension setting.

Beginning with the right hand side,

ensure the cable is in the first groove of

the cable drum. apply light pressure to

the canoe clip on counter cover while

winding springs.

using a power drill (high torque/gear

reduced to 1300 RPM preferred) with a

7/16" socket, carefully rotate right hand

winding bolt clockwise, until counter

shows 2-3 turns.

This will keep the counterbalance cable

taut while adjusting the left hand side

counterbalance cable. adjust left hand

counterbalance cable tension. (refer to

step 28)

NOTE: single spring applications require

no spring winding on left hand side, but

need cable tension adjusted.

NOTE: Ensure counterbalance cable

tension is equal for both sides prior to

fully winding spring(s) to appropriate

number of turns. If cable tension is

unequal refer to step 28.

winding bolt Rotation

CaNOE ClIP

WINDING

BOlT

Power Drill

7/16" socket

Driver

Power Drill

7/16” socket

Driver

7/16" Wrench

29

30

NOTE: apply light pressure to the canoe clip on the

counter cover while winding spring(s).

see the

Spring Turn chart.

For

SINglE SPRINg applications, return to the right hand

side and carefully rotate the winding bolt head clockwise

until the counter shows the correct number of turns for

your door.

For

DOUblE SPRINg applications, remain on the left

hand side and carefully rotate the winding bolt head

clockwise until the counter shows the correct number of

turns for your door. Then return to the right hand side and

wind the right hand spring to the required number of

turns.

IMPORTANT: DO NOT OVERWIND.

after spring is wound, hold the lock nut (in back of end

bracket) stationary on the right hand side with a 7/16”

wrench while rotating the winding bolt clockwise until

snug. Tightening of the lock nut prevents spring from

unwinding. Repeat for opposite side for double spring

TorqueMaster

®

systems.

IMPORTANT: CauTIOusly REMOVE VICE ClaMPs FROM

VERTICal TRaCks. aDjusTMENTs TO ThE

RECOMMENDED NuMBER OF TuRNs May BE REquIRED.

aFTER REaR suPPORT assEMBly Is COMPlETE (sTEP

32), ChECk DOOR BalaNCE. IF DOOR RaIsEs OFF FlOOR

uNDER sPRING TENsION alONE, REDuCE sPRING

TENsION uNTIl DOOR REsTs ON ThE FlOOR. IF ThE

DOOR Is haRD TO RaIsE OR DRIFTs DOWN ON ITs OWN,

aDD sPRING TENsION. aN uNBalaNCED DOOR suCh as

ThIs CaN CausE IDRIVE

®

OPERaTION PROBlEMs.

Setting Spring Tension

RECOMMENDED SPRINg TURNS

Door height

idrive

®

Operated

Doors 11’-11”

wide or less

Manually Operated Door,

and

idrive

®

Operated

Doors 12’ wide or greater

7’-0”

15-1/2

16

8’-0”

17-1/2

18

sPRING TENsION

saMPlE sETTING

NOTE:

For 7’ high doors, 8’, 9’, 10’, 16’ or 18’ wide with

windows, the recommended number of spring turns is 15.

7/16”

WRENCh

lOCk NuT

PRIOR TO WINDING OR MakING aDjusTMENTs TO ThE

sPRINGs, ENsuRE yOu’RE WINDING IN ThE PROPER

DIRECTION as sTaTED IN ThE INsTallaTION INsTRuC-

TIONs. OThERWIsE, ThE sPRING FITTINGs May RElEasE

FROM sPRING IF NOT WOuND IN ThE PROPER DIRECTION

aND COulD REsulT IN sEVERE OR FaTal INjuRy.

wARNINg