Wayne-Dalton TORQUEMASTER 5120 User Manual

Page 17

17

Tools Needed:

Tools Needed:

Please Do Not Return This Product To The Store. Contact your local Wayne-Dalton dealer.

To find your Wayne-Dalton dealer; refer to your local yellow pages / business listings or go to Find a dealer area online at

www.wayne-dalton.com

INST

All

ATION

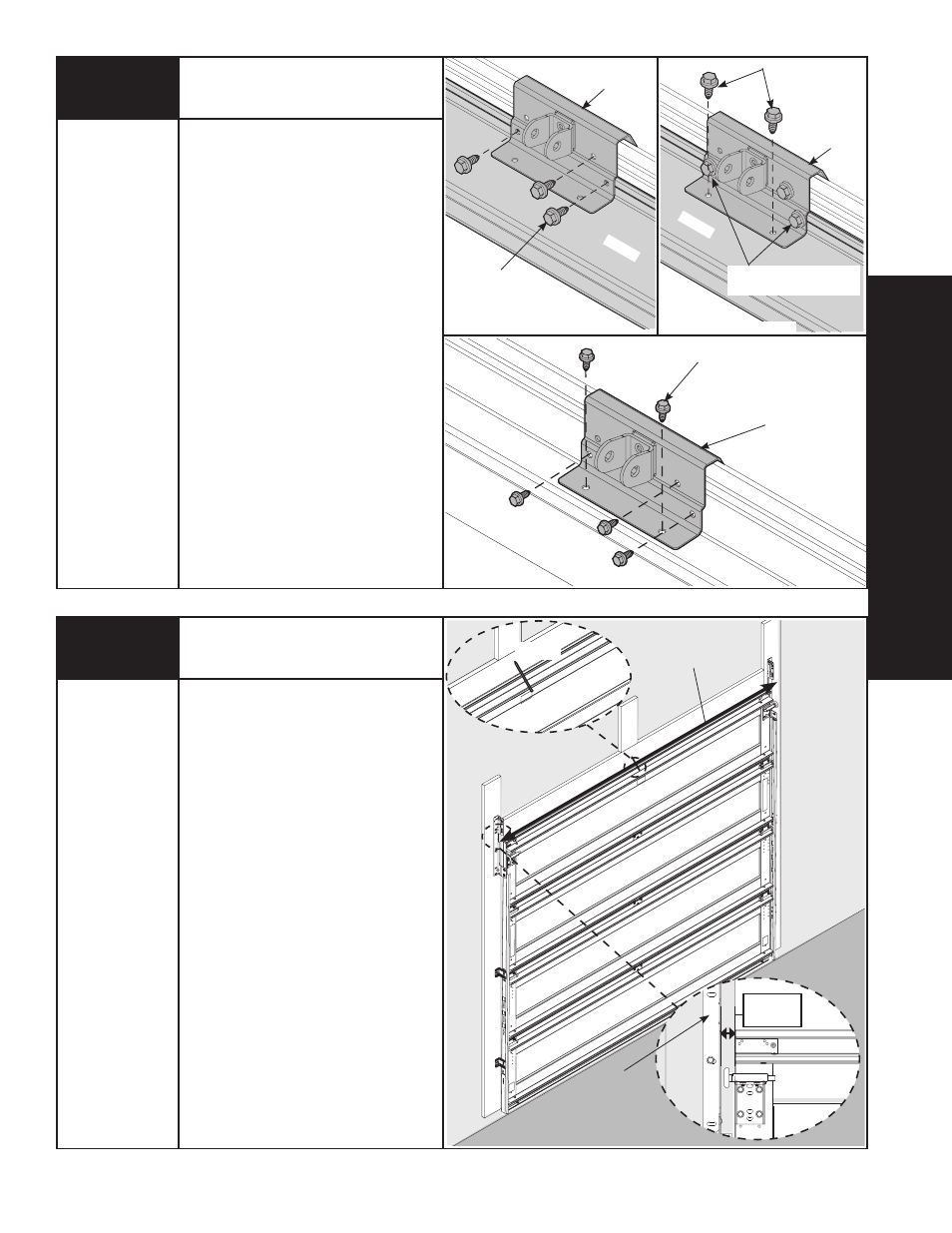

Operator bracket Continued...

Install (2) #12 x 1/2” phillips head

screws on the opposite side of operator

bracket, as shown in FIG. 1.3. C

lamp

operator bracket to u-bar

(if furnished),

as shown in FIG. 1.4. First attach (3)

1/4” - 14 x 5/8” self-tapping screws to

the operator bracket, as shown in FIG.

1.5. Then attach (2) 1/4” - 14 x 5/8”

self-tapping screws to the operator

bracket, as shown in FIG. 1.6.

Remove

vice clamps.

NOTE: If you have a 5120 door, use (2)

of the 1/4” - 20 x 11/16” self-drilling

screws to attach the u-bar instead of

(2)

1/4” - 14 x 5/8” self-tapping screws

when attaching operator bracket to u-

bar, as shown in FIG. 1.6.

NOTE: When attaching operator

bracket to top section with u-bar, apply

additional pressure to thread into the

u-bar.

NOTE: see

FIG. 1.7 for installing operator

bracket on top section without u-bars.

fIg. 1.5

fIg. 1.6

fIg. 1.7

(2) 1/4” - 20 x 11/16”

sElF-DRIllING sCREWs

OPERaTOR

BRaCkET

(2) 1/4” - 14 x 5/8”

sElF-TaPPING

sCREWs

(3) 1/4” - 14 x 5/8”

sElF-TaPPING

sCREWs

OPERaTOR

BRaCkET

OPERaTOR

BRaCkET

(5) 1/4” - 14 x 5/8”

sElF-TaPPING

sCREWs

u-Ba

R

u-Ba

R

Top Section

Place the top section in the opening

and vertically align with lower sections.

Temporarily secure the top section by

driving a nail in the header near the

center of the door and bending it over the

top section. Now flip up hinge leafs, hold

them tight against section and fasten

center hinges first and end hinges last.

(Refer to step 7). When installing a door

with a TorqueMaster

®

counterbalance

system, vertical track alignment is

critical. Position flagangle between 1-

11/16” (43 mm) to 1-3/4” (44 mm) from

the edge of the door. Flagangles must

be parallel to the door sections. Now

complete the vertical track installation

by securing the center jamb bracket and

tightening the other lag screws. Repeat

for other side.

IMPORTANT: ThE DIMENsION BETWEEN

ThE FlaGaNGlEs MusT BE DOOR-

WIDTh Plus 3-3/8” (86 MM) TO 3-1/2”

(89 MM) FOR sMOOTh, saFE DOOR

OPERaTION.

12

hammer

DOOR WIDTh

+3-3/8” TO 3-1/2”

FlaGaNGlE

TOP

sECTION

NaIl

1-11/16”

TO 1-3/4”