5 start up procedure, 1 installation with in-line cleaning systems – Viking SLAL User Manual

Page 7

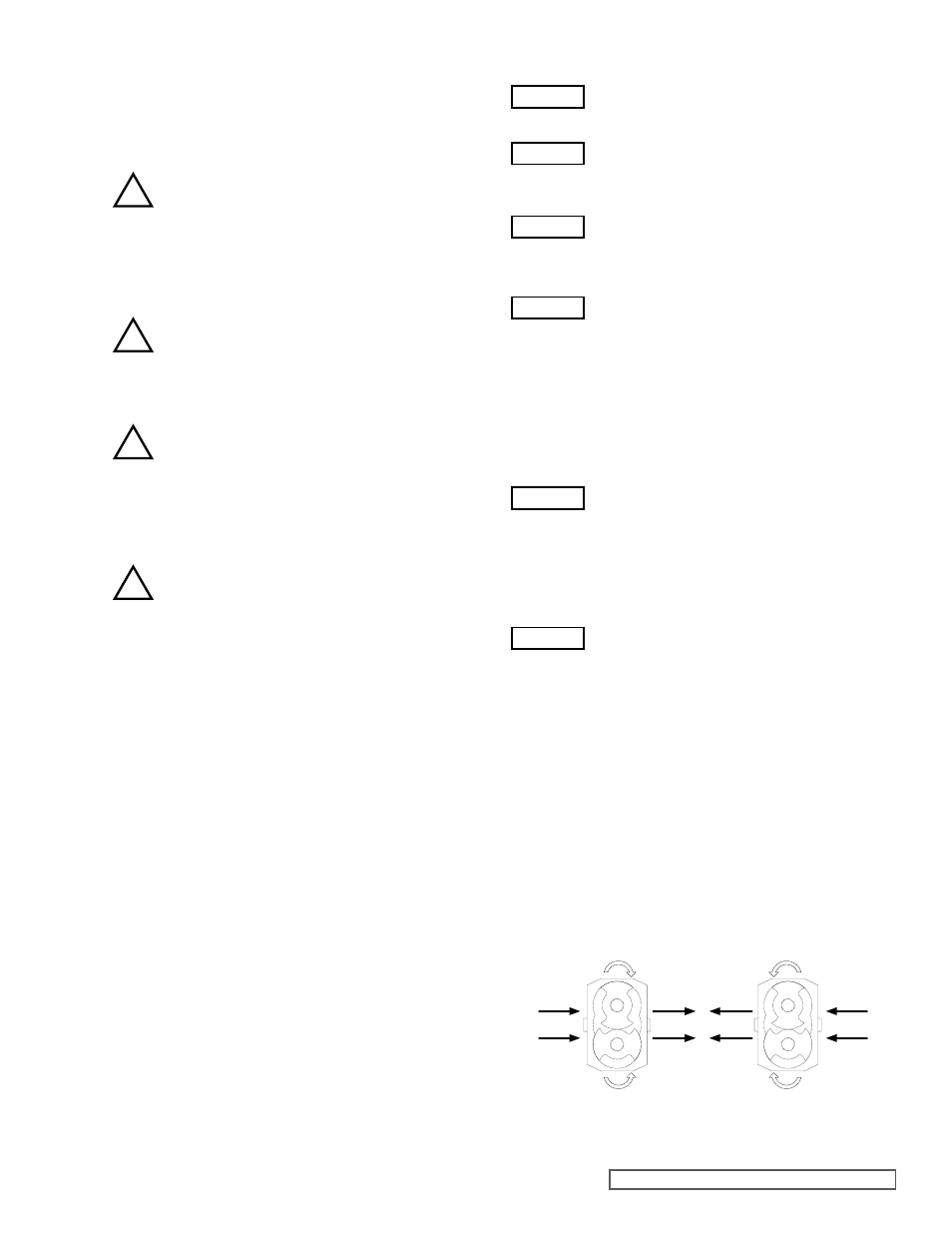

fIGURE 9

ROTaTION

dIsCHaRGE

sUCTION

sUCTION

ROTaTION

SECTION TSM 288

ISSUE

A

PAGE 7 OF 36

3.5 sTaRT UP PROCEdURE

• Check that all piping and associated equipment

are clean and free from debris and that all pipe

connections are secure and leak free.

• For pumps installed with flushed product seals

check that all auxiliary services are in place

and connected and provide sufficient flow and

pressure for flushing purposes

• Ensure lubrication is provided for both pump

and drive. SL Series pumps are shipped pre-

filled with grease, refer to section 6.4 grease

capacities and grades.

• If an external relief valve is incorporated in the

system check that it is set correctly. For start

up purposes it is considered good practice

to set the relief valve lower than the system

design pressure. On completion of start up the

relief valve should be set for the application.

The required setting should never exceed the

lower of either the pumps maximum pressure

rating or the system design pressure. For

setting integral relief valves, refer to sections

3.8.1 and 3.8.2.

• Ensure both suction and discharge valves

are fully open, and pipe work is free from

all obstructions. SL Series pumps are of

the positive displacement type and should

therefore never be operated against a closed

valve as this would result in pressure overload,

resulting in damage to the pump and possibly

the system.

• Ensure rotation of the drive shaft is correct for

the direction of flow required see Figure 9.

• Ensure product is available in the tank before

starting pump. This is very important for pumps

installed with un-flushed product seals, as

these sealing arrangements must never be

allowed to run dry.

• Before beginning operation it is considered

good practice to momentarily start/stop the

pump to check the direction of rotation and

ensure that the pump is free of obstructions.

Once this has been carried out, begin

operation keeping a visual check on suction

and discharge pressure gauges and monitor

pump temperature and power absorbed where

possible.

Where motor mounted options are to be installed follow the

manufactures recommended guidelines. However, when

installing a pump complete with base and drive, the following

guidelines must be observed:

• The preferred drive arrangement for any rotary

lobe pump is in-line direct coupled.

• Flexible couplings must always be incorporated

and correctly aligned within the limits

recommended by the coupling manufacturer.

To check coupling alignment rotate the shaft

by at least one full revolution and ensure that

the shaft rotates smoothly.

Couplings of a non-flexible design must never

be used.

• Couplings must always be enclosed in a suitable

guard to prevent contact with rotating parts that

could result in personal injury. Guards should

be of suitable material, and of sufficiently rigid

design to prevent contact with rotating parts

under normal operating conditions.

• When installing pump sets in flammable

or explosive environments, or for handling

flammable or explosive materials, special

consideration must be given not only to the

safety aspects of the drive unit enclosure

but also to the materials used for both the

coupling and the guard to eliminate the risk of

explosion.

• Baseplates must be secured to a flat level

surface such that distortion and misalignment

are avoided.

Once baseplates are fastened

in position the drive alignment must be re-

checked.

• When using electric motor drives, ensure

that the electrical supply is compatible with

the drive and controls and that the method of

wiring is correct for the type of starting required

by the motor i.e. Direct On Line, or other similar

method. Ensure all components are correctly

grounded.

3.4.1 INsTallaTION WITH IN-lINE

ClEaNING sYsTEMs

The SL Series range has been designed to be effectively

cleaned by procedures recommended for in-line cleaning of

process plant. To assist in maximizing the effectiveness of

cleaning within the pump head it is recommended that during

the cleaning cycle a flow rate equivalent to a velocity of 1.5

metres per second (3.3 feet per second); in a pipe of equal

diameter to the rotor case connections is achieved. With a

differential pressure of 2 to 3 bar (30 to 45 psi) being developed

across the pump head

For applications where maximum drainage of the pump head is

required, and / or where in-line cleaning is employed, the pump

ideally should be mounted with the rotor case connections in

the vertical orientation. A procedure must be determined to

ensure that the pump is effectively cleaned. It is recommended

that this cycle would typically include a combination of some

or all of the following: Acidic or Caustic based Detergents,

‘Sanitizers’, Disinfectants and Water rinses. These must

be appropriate to both the products being handled and the

materials of construction of the pump.

WaRNING

WaRNING

WaRNING

WaRNING

WaRNING

WaRNING

!

!

!

!