2 pump assembly slg 4.2.1 shaft assembly – Viking SLAL User Manual

Page 18

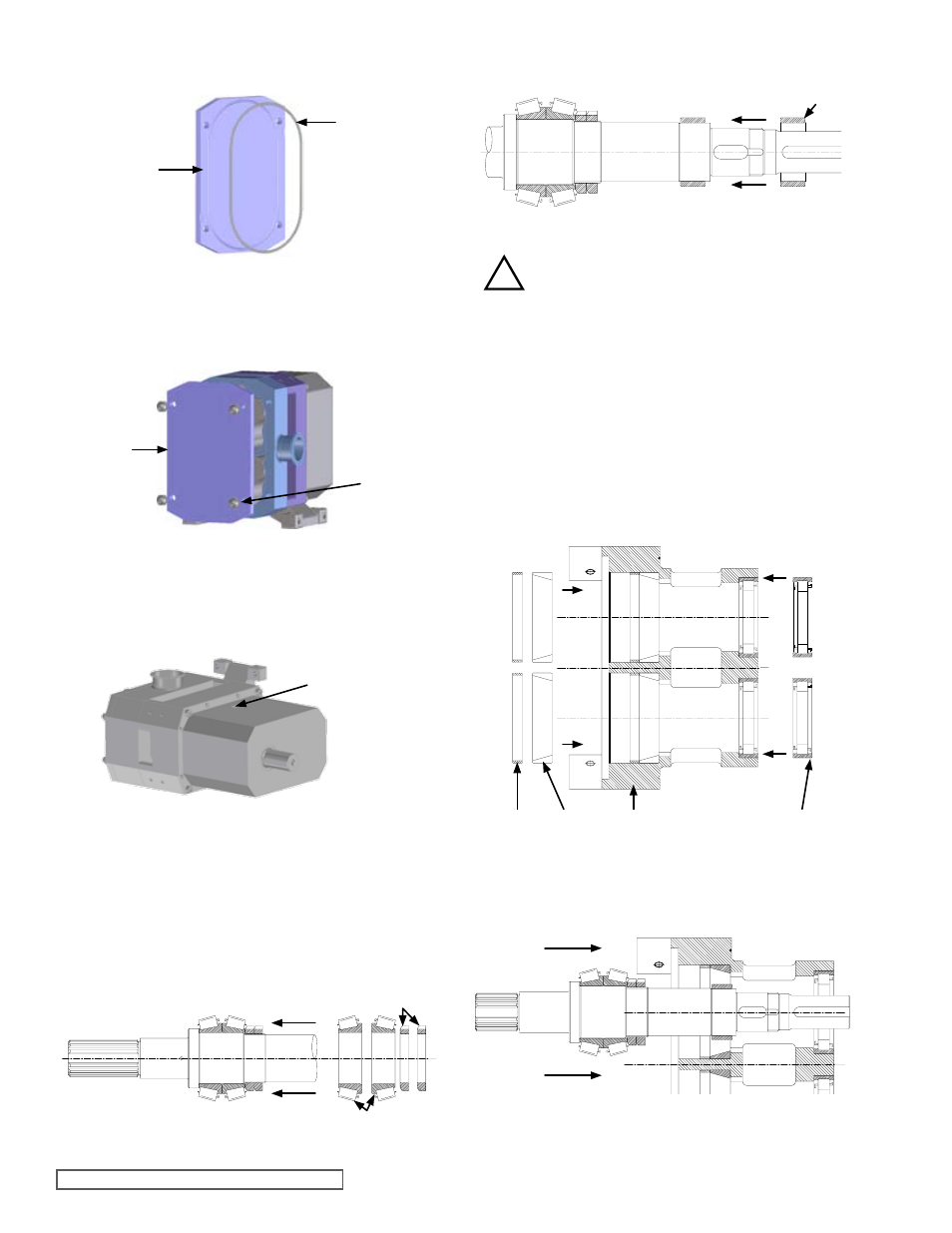

fIGURE 44

5.04

fIGURE 45

4.10

5.03

4.10

5.04

fIGURE 46

fIGURE 43

5.16

5.03

fIGURE 42II

fIllING POINT

fIGURE 42I

1.01

1.03

fIGURE 41

1.02

1.01

SECTION TSM 288

ISSUE

A

PAGE 18 OF 36

NOTE: The preferred method of installing bearing

cones is that they are heated to approximately

125°C (250°F) prior to installation. During this

operation protective gloves should be used.

Once bearing cones are installed in correct

position they should be allowed to cool before

proceeding with assembly. As an alternative,

bearing cones may be pressed into position

providing the proper equipment is employed and

the necessary procedures are used to prevent

component damage.

Under no circumstances should bearing cones or cups be

hammered into position.

• Install Bearing cups (5.03, 5.04) and the bearing pre-load

adjustment spacer (4.10) into the bearing housing (4.01)

• Install the needle roller inner race (5.04)

• Install the shaft assembly into the bearing housing.

4.2 PUMP assEMblY slG

4.2.1 sHafT assEMblY.

• Install the bearing cones (5.03) see Figure 43 and secure

using the two locknuts (5.16) see section 6.2 for torque

settings.

• Install the head O-ring (1.02) into the head (1.01)

• Install the head (1.01) and secure with the dome nuts (1.03).

(See section 6.2 for torque settings)

• Rotate the pump so filler hole is uppermost, add lubricant.

(See section 6.4 for lubricants and quantities)

!