3 sl series pump operating parameters, 2 rotary lobe pump principle – Viking SLAL User Manual

Page 5

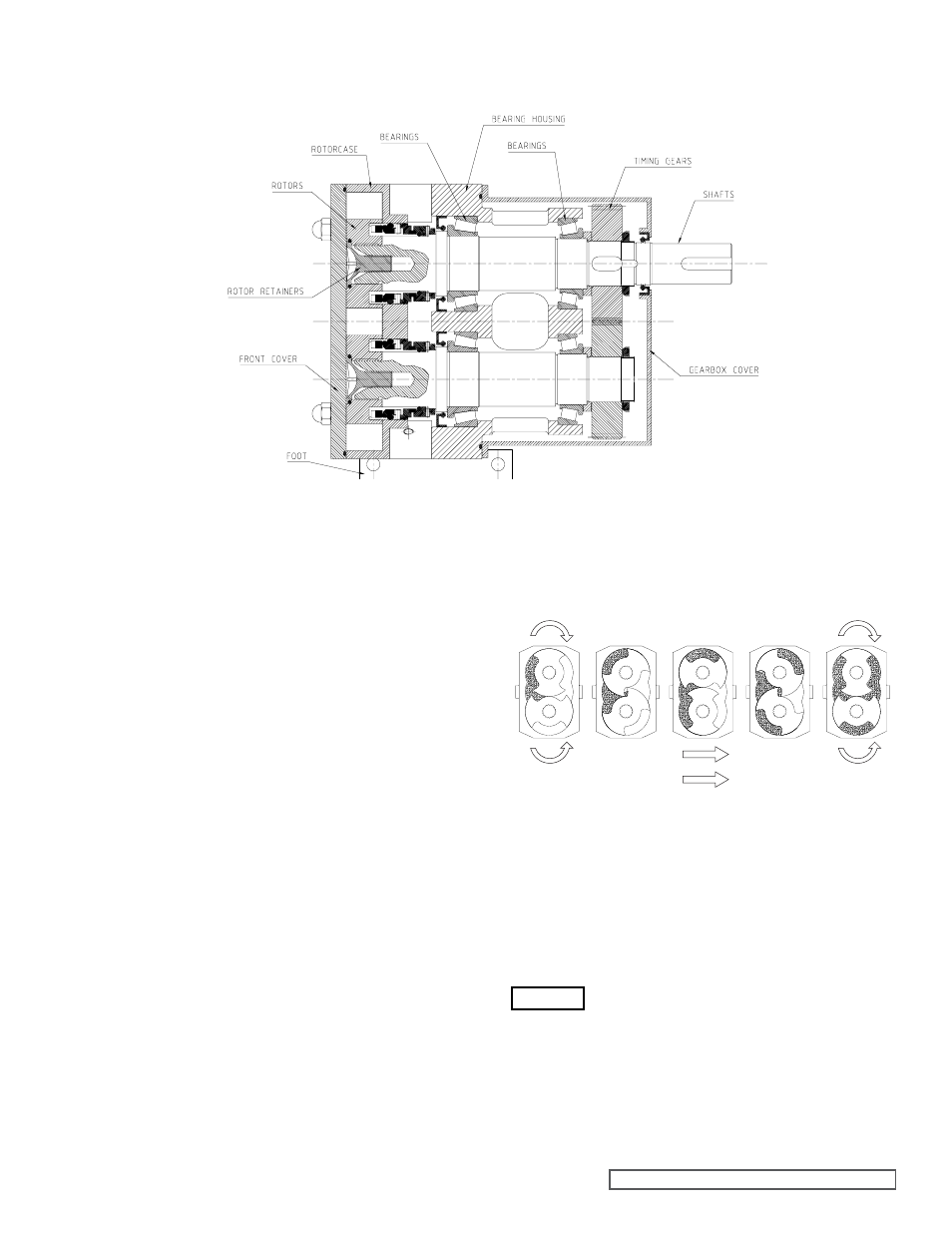

fIGURE 5

fIGURE 6

6a

6b

6c

6d

6e

flOW

SECTION TSM 288

ISSUE

A

PAGE 5 OF 36

3.3 sl sERIEs PUMP OPERaTING

PaRaMETERs

The maximum pressure and speed operating parameters are

given in Figure 7, page 6. In practice these may be limited due

to the nature of the product to be pumped and/or design of the

system in which the pump is to be installed. Consult Viking

Pump or your distributor for assistance.

If the system or product characteristics are to be changed

from the original application for which the pump was

selected, Viking Pump or their authorized distributor should

be consulted to ensure the pump is suitable for the new

application.

The pump should not be subjected to sudden temperature

changes to avoid the risk of damage from sudden

expansion/contraction of components. Care should be

taken when selecting pumps for handling liquids containing

abrasive particles as these may cause wear of pump head

components. For advice or assistance contact your Viking

Pump distributor.

2.8 sTaNdaRd PUMP

COMPONENT TERMs

3.0 GENERal

3.1 sl sERIEs PUMPING

PRINCIPlE

The pumping action of the rotary lobe pump principle is

generated by the contra-rotation of two pumping elements

(rotors) within a chamber (casing) see Figure 6.

The rotors are located on shafts that in turn are held within a

bearing housing mounted to the back of the casing. The shaft

assemblies comprise of, the shaft support bearings and the

timing gears. The gears transfer the energy from the drive

shaft to the driven shaft, synchronizing the rotors such that

they rotate without contact with each other.

As the rotors pass the suction port, Figure 6a, the cavity

increases creating a pressure decrease, which induces the

pumped medium to flow into the casing.

The pumped medium is carried around the casing by the

rotors, Figure 6b and 6c, to the discharge side of the pump,

Figure 6d. Here the cavity decreases and the pumped medium

is discharged from the casing, Figure 6e.

For pump component terms see Figure 5.

3.2 ROTaRY lObE PUMP

PRINCIPlE

WaRNING