8 paper feed specifications, 1 paper feed methods/paths, 2 paper positioning restrictions – Oki POS 425D User Manual

Page 92: 3 paper tear-off, 4 paper end detection

92

OKIPOS 425D

|

5.8 Paper Feed Specifications

5.8.1 Paper feed methods/Paths

a

Friction feed

For Cut-sheet paper

b

Friction feed

For Roll paper

c

Push tractor feed (Front path)

For Sprocket paper (Tractor)

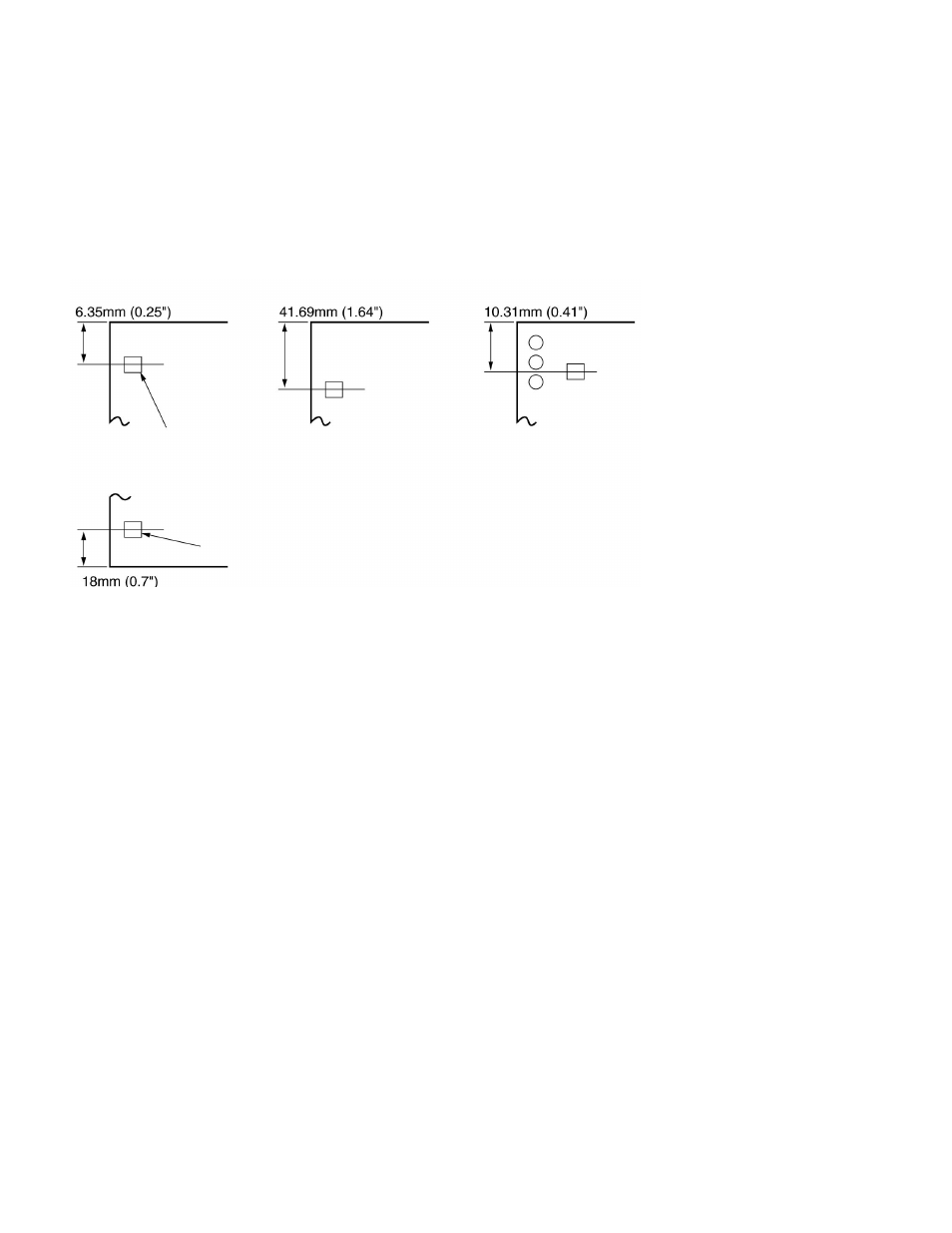

5.8.2 Paper Positioning Restrictions

OP425_31.eps

1

Cut-sheet paper (slip)

2

Roll paper

3

Sprocket paper (Tractor)

4

Printing position on the first line

5

Printing position on the last line

6

Cut-sheet paper (Counterfoil, Stub)

5.8.3 Paper Tear-off

Roll paper

The paper can be torn off 41.69mm (1.64 inch) above the first printed line. A sharp serrated edge is provided on the top

cover for paper tear-off.

Sprocket paper (Tractor)

The paper can be torn off 35.96mm (1.42 inch) above the first printed line. A sharp serrated edge is provided on the access

cover for paper tear-off.

5.8.4 Paper End Detection

1

With cut-sheet paper feed, the paper end is detected when the remaining paper length is about 19.6mm (0.77 inch) from

the last printed line.

2

With roll paper feed, the paper end is detected when the remaining paper length is about 87.83mm (3.46 inch) from the last

printed line.

3

With Sprocket paper (Tractor) feed, the paper end is detected when the remaining paper length is about 19.6mm (0.77

inch) from the last printed line.

4

Upon detecting the paper end, the printer stops printing and sends a paper end signal to the interface.

1

2

3

4

5

6