Part 3 - pre-installation checkout – Omega FD6003 User Manual

Page 17

3-1

PART 3 - PRE-INSTALLATION CHECKOUT

After unpacking, it is recommended to save the shipping

carton and packing materials in case the instrument is

stored or re-shipped. Inspect the equipment and carton

for damage. If there is evidence of shipping damage,

notify the carrier immediately.

The FD6000 Series flowmeter can be checked for basic

functionality using the following Bench Test procedure.

It is recommended that this operation be performed

before permanently installing the system.

Procedure:

1. Open the transmitter cover.

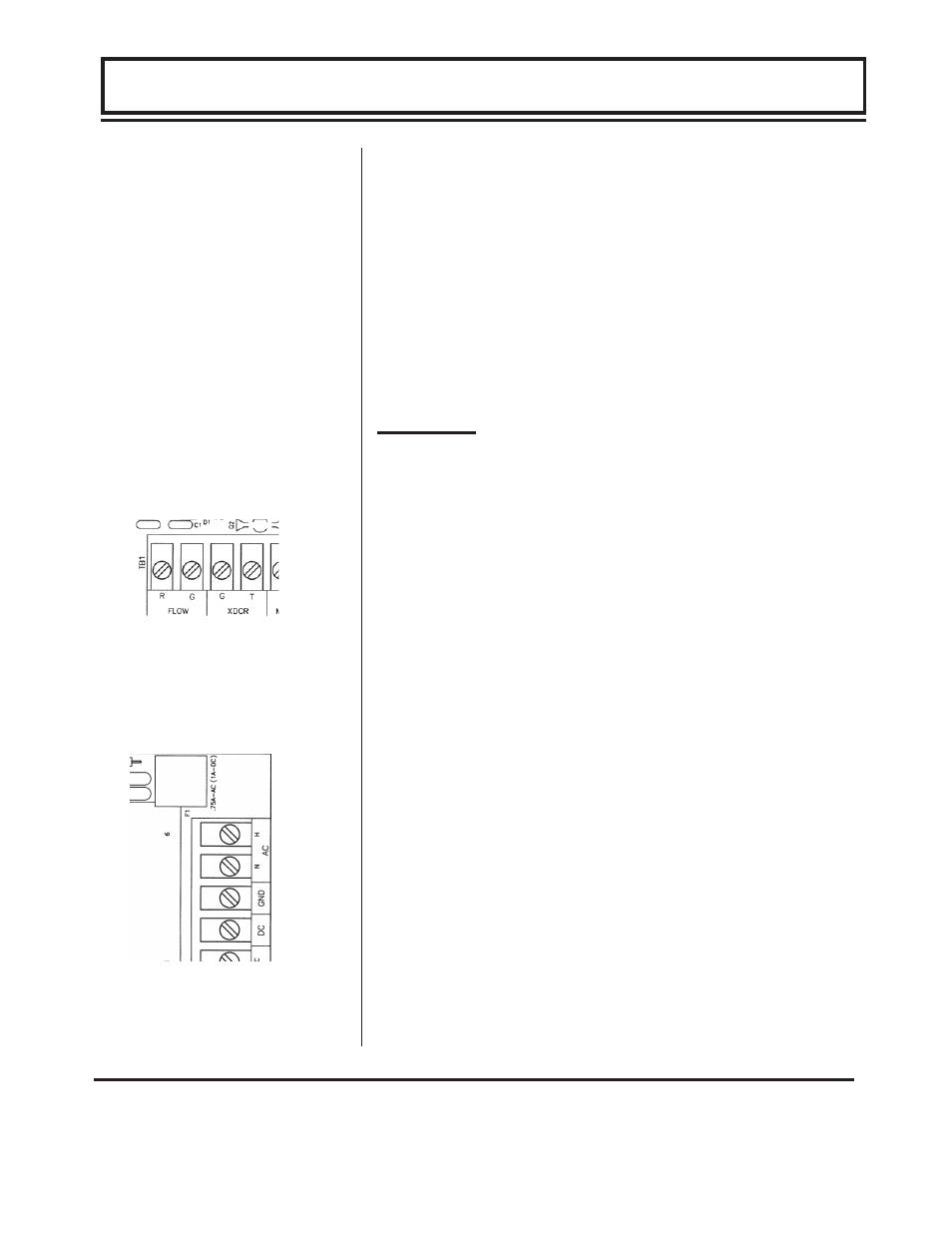

2. Connect the transducer cable connector to the

terminal locations on the lower left corner of the

FD6000 Series main circuit card. See Figure 3.1.

3. Connect supply power to the appropriate terminal

locations on the upper right corner of the main circuit

card. See Figure 3.2. Verify that the power supply

selection jumpers are configured properly—See

Figure 3.4.

4. Apply power.

5. Verify that the display indicates 0.00 FPS (or 0.0 flow

rate of any other unit). If the display does not register

0.0, then press the 2nd FUNCT key, then press

SIGNAL STR. Verify that SIGNAL STR. is lower than

000100. If SIGNAL STR. is greater than 000100,

verify that the sensor/transmitter are not located near

electrically noisy components. (VFDs, inverters,

motors, power relays, etc) Verify that transducer

connections are proper and secure. If the SIGNAL

STR. remains greater than 000100, consult the

Dynasonics Factory for assistance.

6. Press the 2nd FUNCT key to enter SERVICE MODE.

Press the SIGNAL STR key to display SIGNAL STR.

XXXXXX.

7. Rub the face of the transducer lengthwise back and

Unpacking

Functional Test

Figure 3.2

Figure 3.1