Raypak 500 User Manual

Page 43

43

–0.5 in. WC from the reading recorded on the

start-up checklist.

3. The desired combustion CO2 is between 8.5%

and 9.0% for natural gas and 9.0% and 9.5% for

propane with CO less than 150 ppm. Combustion

should be checked at high and low fire (Max. and

Min. fan speed) by using the service mode. Enter

the service mode by pressing the UP arrow key

and ENTER/MENU key simultaneously for 1 sec-

ond. Set the fan speed using the UP and DOWN

arrow keys.

Manifold Check

1. Check manifold gas pressure at the manifold pres-

sure tap (connection “D” in Fig. 35). This pressure

should read per the values in Table S for natural

and propane gas.

2. If the pressure reading differs by more than ± 0.2

in. WC, STOP – Call the factory for directions

on what to do next!

Safety Inspection

1. Check all thermostats and high limit settings.

2. During the following safety checks leave manome-

ters hooked up, check and record.

3. If other gas-fired appliances in the room are on the

same gas main, check all pressures on the XFyre

with all other equipment running.

4. Check thermostats for ON-OFF operation.

5. Check high limits for ON-OFF operation.

6. While in operation, check flow switch operation.

7. Check the low gas pressure switch (if provided).

(For proper adjustment, use the attached

manometers, if available, to set pressure. The

scales on the switch are approximate only.) Low

gas pressure switch (if provided) must be set at

3.0 in. WC for natural gas and propane gas.

8. Make sure that the high gas pressure switch (op-

tional) is set to 3.0 in. WC for both natural gas and

propane gas.

Follow-Up

Safety checks must be recorded as performed.

Turn boiler on. After main burner ignition:

1. Check manometer for proper readings.

Specifically note the change in air intake pressure.

Replace the filter if necessary. (Refer to Table Q.)

2. Cycle unit several times and re-check readings.

3. Remove all manometers and replace caps and

screws.

4. Check for gas leaks one more time.

CAUTION: Special manifold and air settings may

be required.

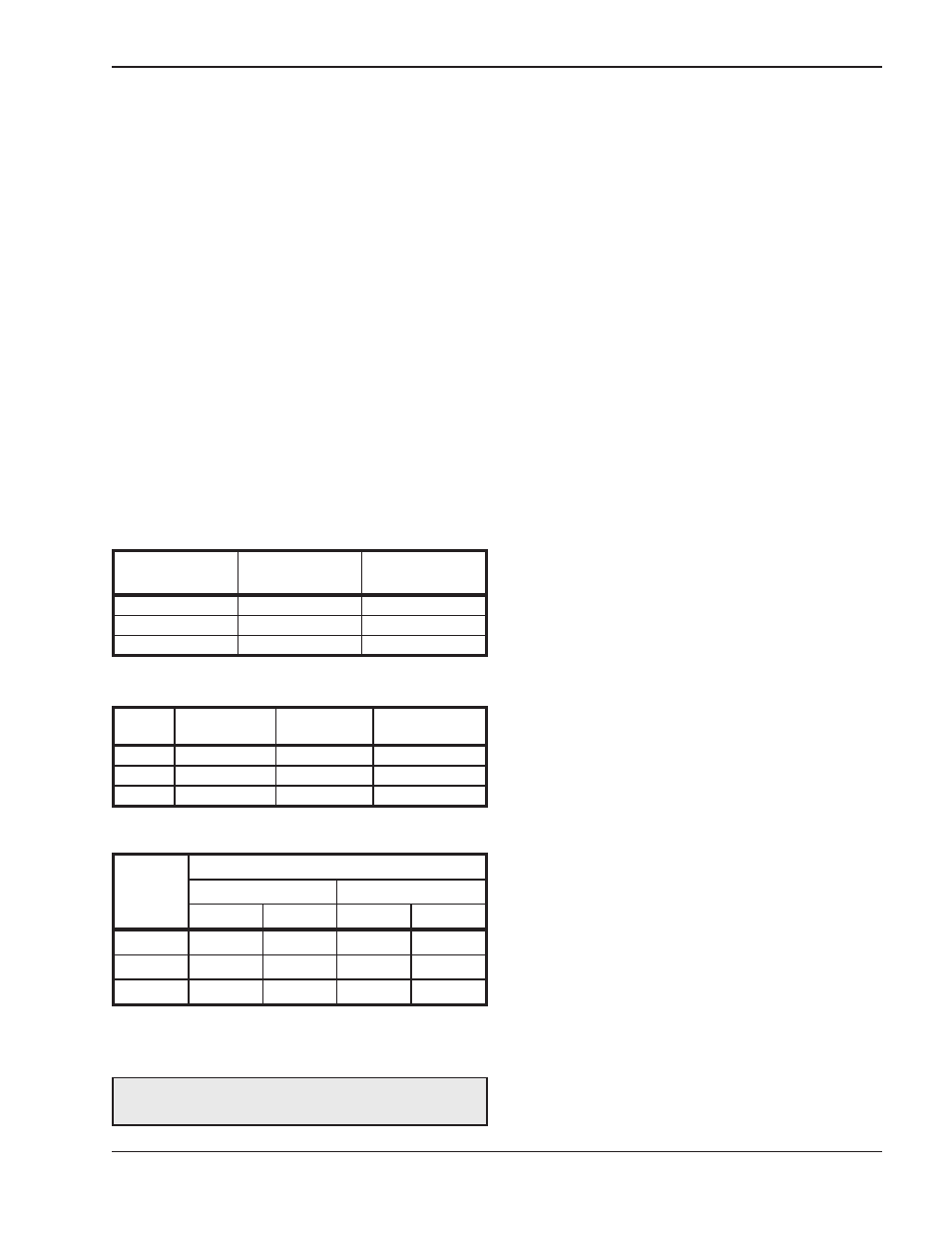

Model

Air Pressure

Setting (in. WC)

Setting

Tolerance

300

-0.1

± 0.2 in. WC

500

-0.2

± 0.2 in. WC

850

-0.3

± 0.2 in. WC

Table Q: XFyre Intake Air Pressure Settings (High Fire)

Model

High Fire

Ignition

Low Fire

300

5000

3000

1500

500

7600

3000

1750

850

5500

3000

1500

Table R: XFyre Fan Speed Settings

Table S: XFyre Manifold Pressure Settings

Finishing

1. Record all data on the “Start-up Checklist” located

at the back of this manual.

2. Disconnect the manometers and reconnect the

cap on the air intake and reinsert or close the seal-

ing screws into the bleedle valves.

3. Start-up is complete and the boiler should be oper-

ating properly.

Model

No.

Manifold Pressure (in. WC)

Natural Gas

Propane Gas

High

Low

High

Low

300

-0.2

-0.1

-0.2

-0.1

500

-0.3

-0.1

-0.3

-0.1

850

-3.2

-0.2

-2.7

-0.1

NOTE: Manifold pressures should be ±0.3 in. WC.