Raypak 500 User Manual

Page 27

27

mon venting system are located and other spaces

of the building. Turn on clothes dryers and any

appliance not connected to the common venting

system. Turn on any exhaust fans, such as range

hoods and bathroom exhausts, so they will oper-

ate at maximum speed. Do not operate a summer

exhaust fan. Close fireplace dampers.

(d) Place in operation the appliance being inspected.

Follow the lighting instructions. Adjust thermostat

so appliance will operate continuously.

(e) After it has been determined that each appliance

remaining connected to the common venting sys-

tem properly vents when tested as outlined above,

return doors, windows, exhaust fans, fireplace

dampers and any other gas burning appliance to

their previous conditions of use.

(f) Any improper operation of the common venting

system should be corrected so that the installation

conforms with the latest edition of the National

Fuel Gas Code, ANSI Z223.1 and/or CAN/CSA

B149. When re-sizing any portion of the common

venting system, the common venting system

should be re-sized to approach the minimum size

as determined using the appropriate tables in Part

11 of the National Fuel Gas Code, ANSI Z223.1

and/or CAN/CSA B149.

WARNING: Vent connectors serving any other

appliances shall not be connected into any portion of

mechanical draft systems operating under a positive

pressure. If an XFyre boiler is installed to replace an

existing boiler, the vent system MUST be verified to

be of the correct size and of Category IV AL29-4C

vent material or approved PVC/CPVC construction

(in Canada, ULC-S636 approved plastic materials

must be used). If it is NOT, it MUST be replaced.

NOTE: For extractor sizing, typical CO

2

levels are

8.5% for natural gas and 9.5% for propane gas and

flue temperatures of approximately 150°F.

NOTE: Data for 100% firing rate.

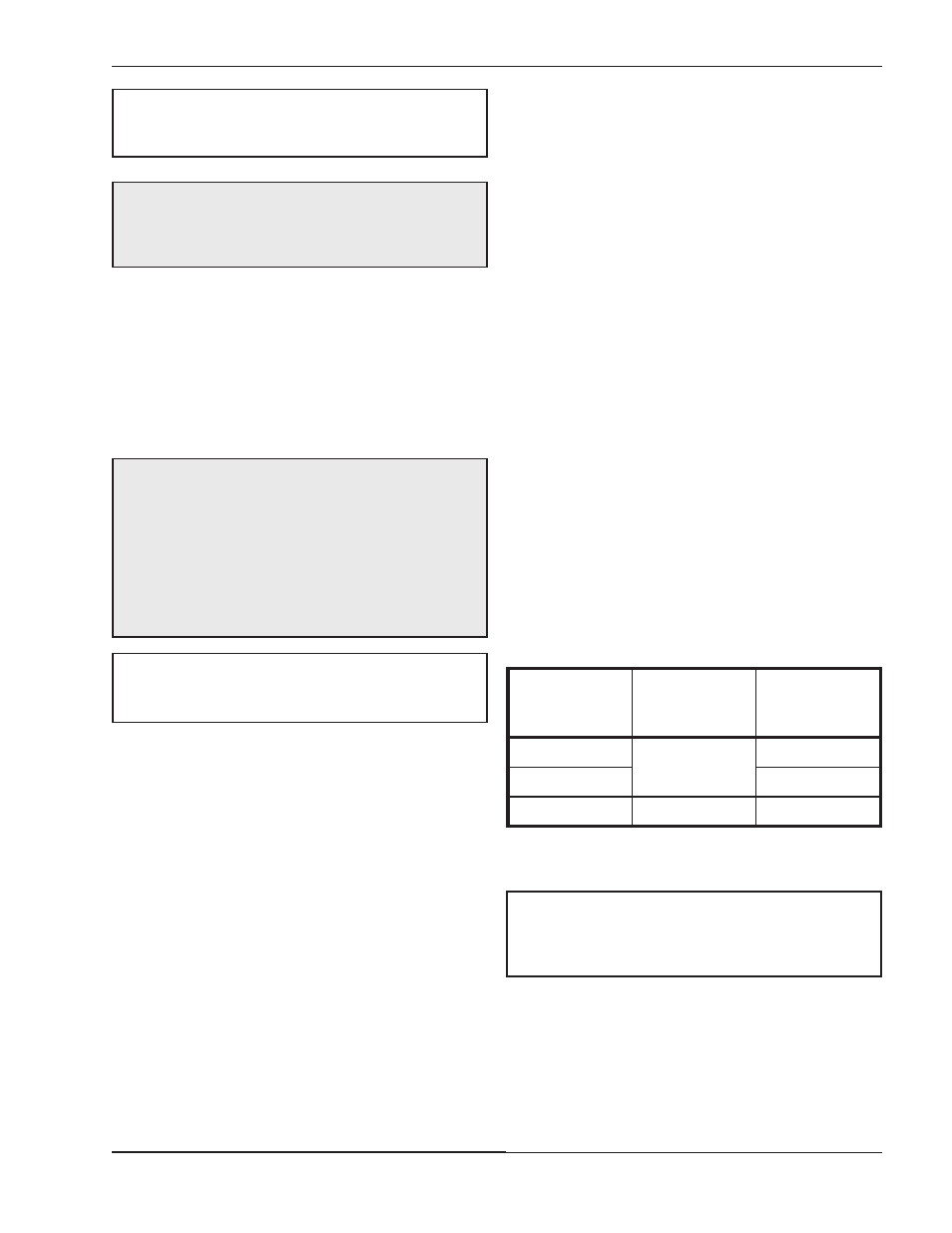

Table M: Volume of Flue Products Data

CAUTION: A listed vent cap terminal suitable for

connection to the Cat IV vent materials, adequately

sized, must be used to evacuate the flue products

from the boilers.

Common Venting

The NFGC does not address sizing guidelines for the

common venting of multiple Category IV heaters. This

is covered in the NFGC under “Engineered Vent Sys-

tems”. Table M provides volumes of flue products at

full fire for the calculation of appropriate vent and

extractor sizing for common venting.

Model No.

Vent Size

(inches)

Volume of

Flue Products

(CFM)

300

4

80

500

130

850

6

220

At the time of removal of an existing boiler, the follow-

ing steps shall be followed with each appliance

remaining connected to the common venting system

placed in operation, while the other appliances remain-

ing connected to the common venting system are not

in operation:

(a) Seal any unused openings in the common venting

system.

(b) Visually inspect the venting system for proper size

and horizontal pitch and make sure there is no

blockage or restriction, leakage, corrosion and

other deficiencies which could cause an unsafe

condition.

(c) As much as possible, close all building doors and

windows and all doors between the space in which

the appliances remaining connected to the com-

NOTE: Vent and intake piping must be supported so

that the weight of the venting is not transfered to the

unit. Horizontal runs of vent and intake piping must

be supported to prevent sagging.

NOTE: When using PVC vent termination, insert the

round stainless mesh screens provided with the unit

into the tee and terminals.