4 reflow soldering, Tda5051a, Nxp semiconductors – Philips TDA5051A User Manual

Page 24

TDA5051A

All information provided in this document is subject to legal disclaimers.

© NXP B.V. 2011. All rights reserved.

Product data sheet

Rev. 5 — 13 January 2011

24 of 29

NXP Semiconductors

TDA5051A

Home automation modem

•

Process issues, such as application of adhesive and flux, clinching of leads, board

transport, the solder wave parameters, and the time during which components are

exposed to the wave

•

Solder bath specifications, including temperature and impurities

16.4 Reflow soldering

Key characteristics in reflow soldering are:

•

Lead-free versus SnPb soldering; note that a lead-free reflow process usually leads to

higher minimum peak temperatures (see

Figure 25

) than a SnPb process, thus

reducing the process window

•

Solder paste printing issues including smearing, release, and adjusting the process

window for a mix of large and small components on one board

•

Reflow temperature profile; this profile includes preheat, reflow (in which the board is

heated to the peak temperature) and cooling down. It is imperative that the peak

temperature is high enough for the solder to make reliable solder joints (a solder paste

characteristic). In addition, the peak temperature must be low enough that the

packages and/or boards are not damaged. The peak temperature of the package

depends on package thickness and volume and is classified in accordance with

Table 9

and

10

Moisture sensitivity precautions, as indicated on the packing, must be respected at all

times.

Studies have shown that small packages reach higher temperatures during reflow

soldering, see

Figure 25

.

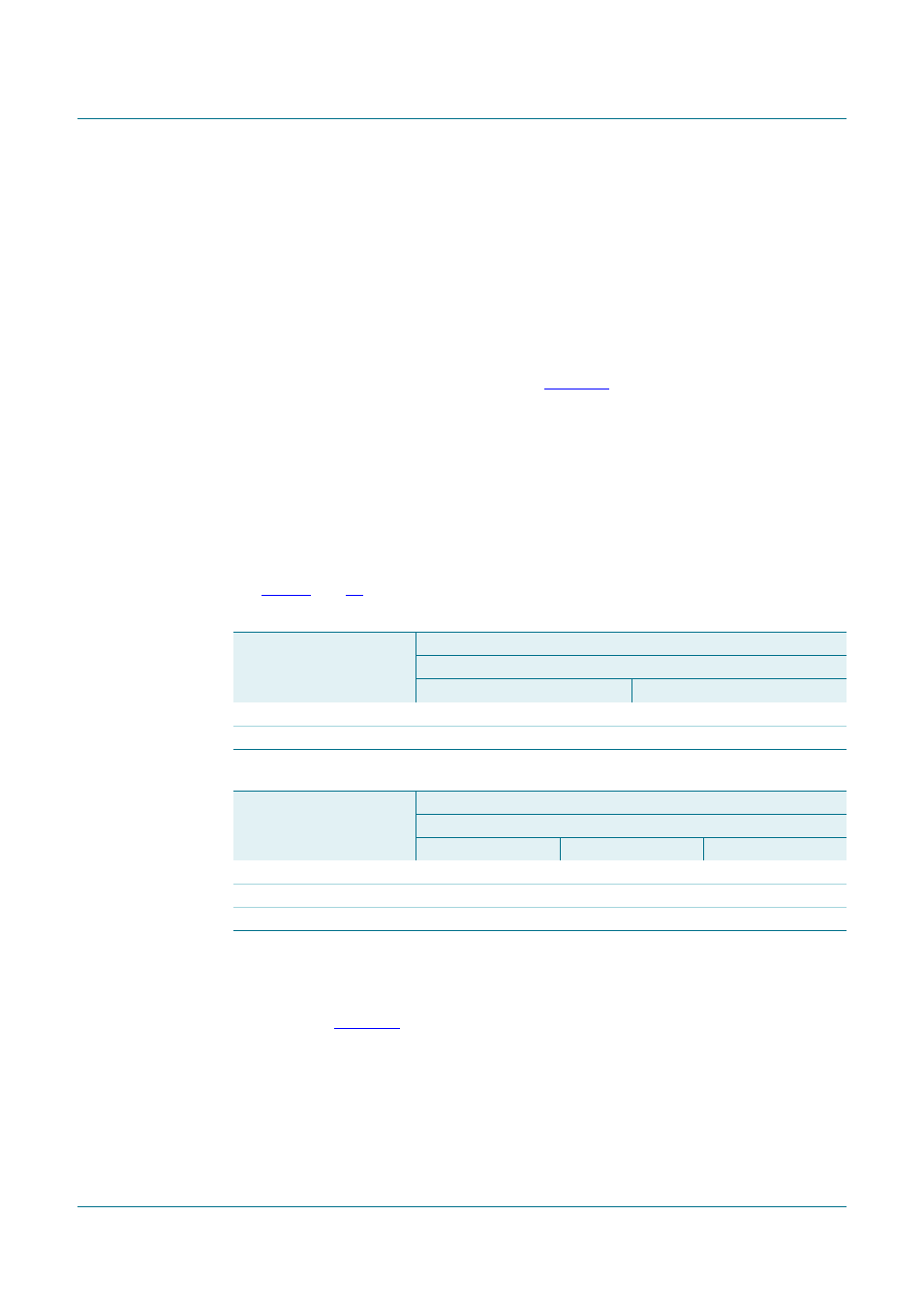

Table 9.

SnPb eutectic process (from J-STD-020C)

Package thickness (mm)

Package reflow temperature (

°C)

Volume (mm

3

)

< 350

≥ 350

< 2.5

235

220

≥ 2.5

220

220

Table 10.

Lead-free process (from J-STD-020C)

Package thickness (mm)

Package reflow temperature (

°C)

Volume (mm

3

)

< 350

350 to 2000

> 2000

< 1.6

260

260

260

1.6 to 2.5

260

250

245

> 2.5

250

245

245