Gas connections, Propane gas, Natural gas – Lochinvar Sync Condensing Boiler 1 User Manual

Page 35

35

Installation & Operation Manual

6

Gas connections

(continued)

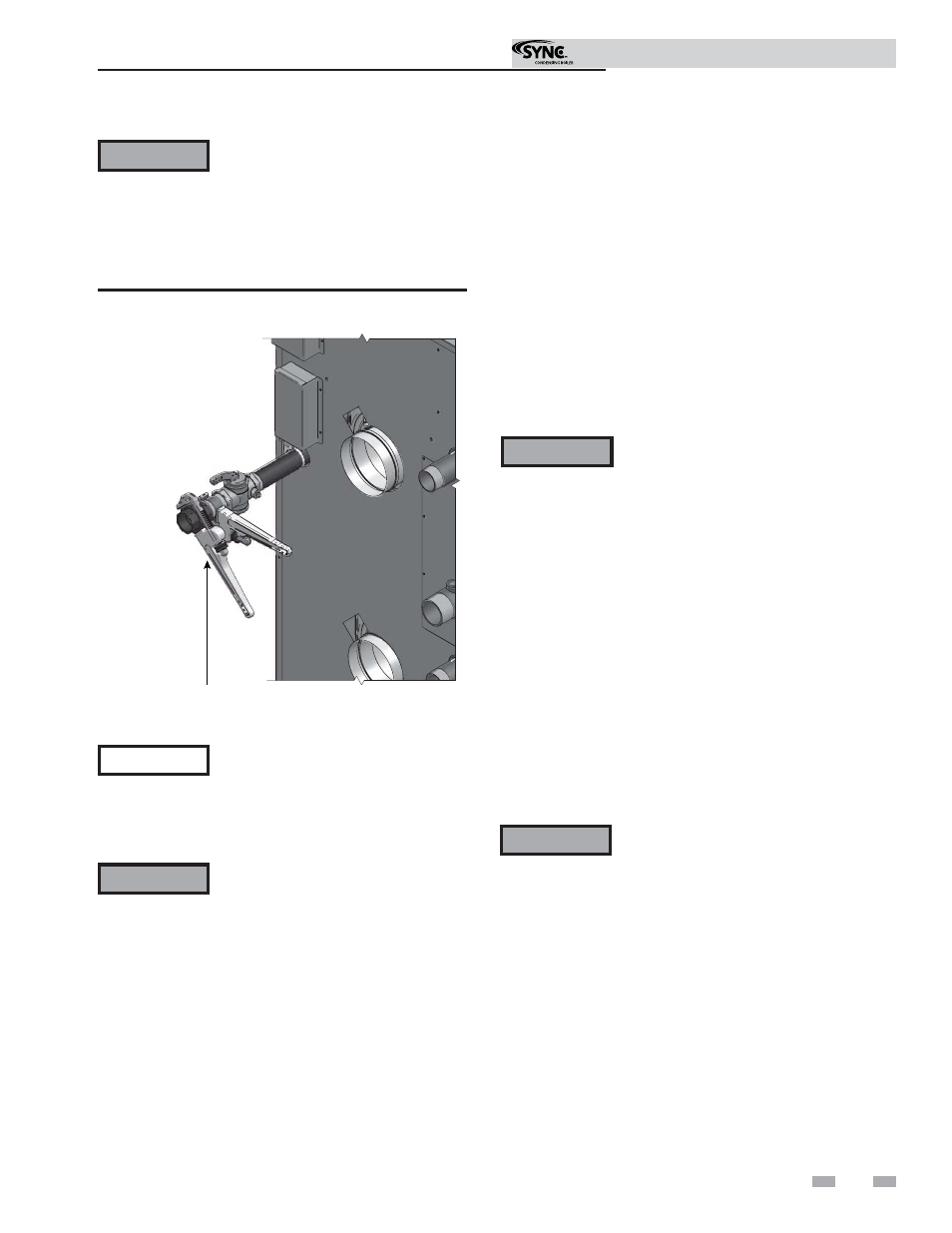

Use two wrenches when tightening gas

piping at boiler (FIG. 6-2), using one

wrench to prevent the boiler gas line

connection from turning. Failure to

support the boiler gas connection pipe

to prevent it from turning could damage

gas line components.

USE BACK UP WRENCH TO

PREVENT PIPE FROM ROTATING

Figure 6-2 Inlet Pipe with Backup Wrench

Natural gas supply pressure requirements

1. Pressure required at the gas valve inlet pressure port:

• Maximum 14 inches w.c. (3.5 kPa) with no flow

(lockup) or with boiler on.

• Minimum 5 inches w.c. (1.25 kPa) for 1.0 models with gas

flowing (verify during boiler startup).

• Minimum 4 inches w.c. (.99 kPa) for 1.3 - 1.5 models with

gas flowing (verify during boiler startup).

2. Install 100% lockup gas pressure regulator in supply line

if inlet pressure can exceed 14 inches w.c. (3.5 kPa) at any

time. Adjust lockup regulator for 14 inches w.c. (3.5 kPa)

maximum.

Propane Gas:

Pipe sizing for propane gas

1. Contact gas supplier to size pipes, tanks, and 100% lockup

gas pressure regulator.

Propane Supply Pressure Requirements

1. Adjust propane supply regulator provided by the gas

supplier for 14 inches w.c. (3.5 kPa) maximum pressure.

2. Pressure required at gas valve inlet pressure port:

• Maximum 14 inches w.c. (3.5 kPa)with no flow (lockup)

or with boiler on.

• Minimum 8 inches w.c. (1.9 kPa) with gas flowing (verify

during boiler startup).

Maximum inlet gas pressure must not

exceed the value specified. Minimum

value listed is for the purposes of input

adjustment.

ƽ WARNING

ƽ WARNING

NOTICE

ƽ WARNING Ensure that the high gas pressure regulator

is at least 10 feet (3 m) upstream of the

appliance.

Check boiler rating plate to determine which

fuel the boiler is set for. SYNC boilers CAN

NOT be field converted. Failure to comply

could result in severe personal injury, death,

or substantial property damage.

ƽ WARNING

Check boiler rating plate to determine

which fuel the boiler is set for. SYNC

boilers CANNOT be field converted.

Failure to comply could result in severe

personal injury, death, or substantial

property damage.

Natural gas:

Pipe sizing for natural gas

1. Refer to Table 6A for pipe length and diameter. Based on

rated boiler input (divide by 1,000 to obtain cubic feet per

hour).

a.

Table 6A is only for natural gas with specific gravity

0.60 inches, with a pressure drop through the gas

piping of 0.5 inches w.c.

b. For additional gas pipe sizing information, refer to

ANSI Z223.1 (or B149.1 for Canadian installations).