Determine boiler location – Lochinvar Sync Condensing Boiler 1 User Manual

Page 10

Installation & Operation Manual

10

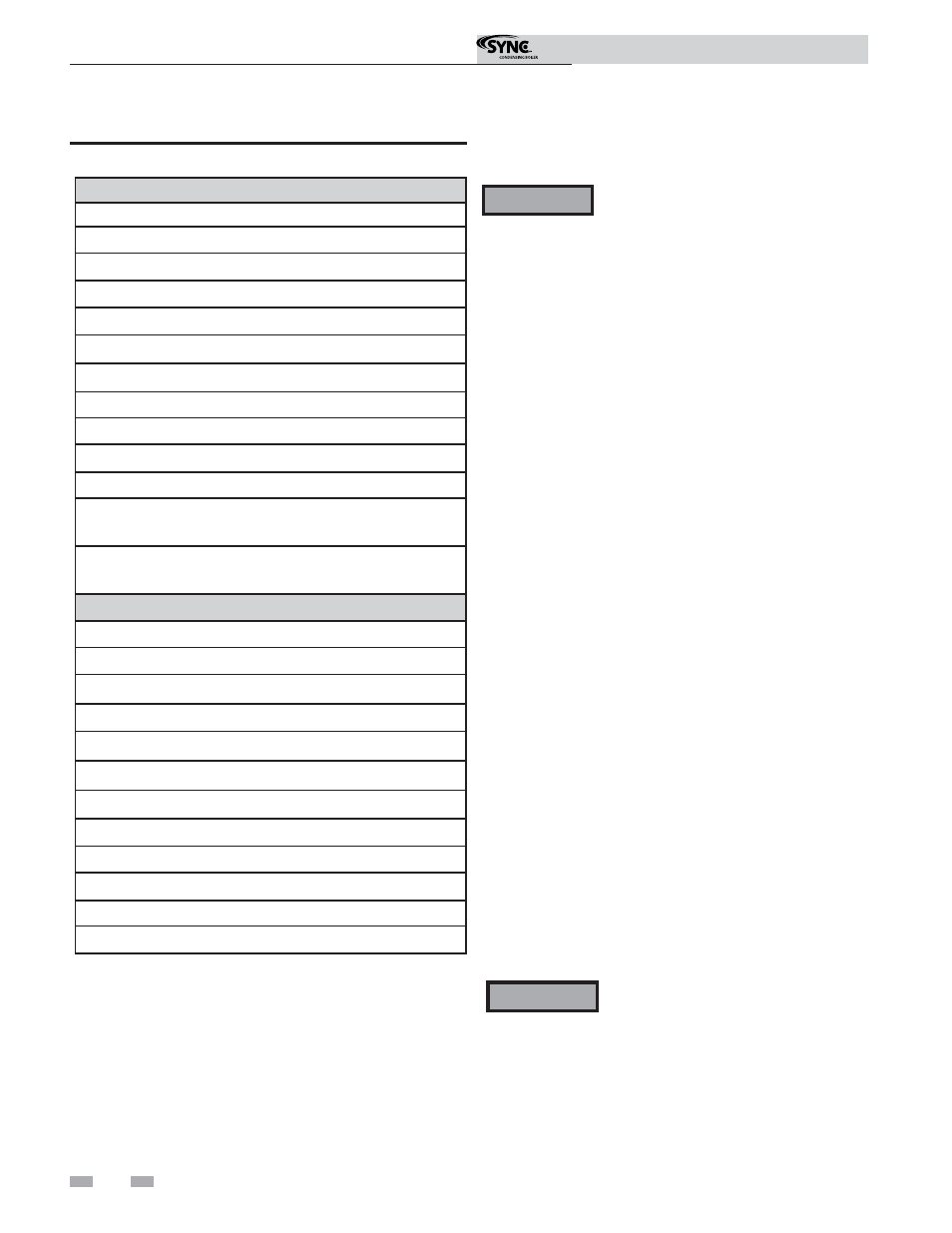

Products to avoid:

Spray cans containing chloro/fluorocarbons

Permanent wave solutions

Chlorinated waxes/cleaners

Chlorine-based swimming pool chemicals

Calcium chloride used for thawing

Sodium chloride used for water softening

Refrigerant leaks

Paint or varnish removers

Hydrochloric acid/muriatic acid

Cements and glues

Antistatic fabric softeners used in clothes dryers

Chlorine-type bleaches, detergents, and cleaning solvents

found in household laundry rooms

Adhesives used to fasten building products and other similar

products

Areas likely to have contaminants

Dry cleaning/laundry areas and establishments

Swimming pools

Metal fabrication plants

Beauty shops

Refrigeration repair shops

Photo processing plants

Auto body shops

Plastic manufacturing plants

Furniture refinishing areas and establishments

New building construction

Remodeling areas

Garages with workshops

Table 1A Corrosive Contaminants and Sources

1

Determine boiler location

Failure to follow all instructions can result

in flue gas spillage and carbon monoxide

emissions, causing severe personal injury

or death.

ƽ WARNING

When using an existing vent system to

install a new boiler:

ƽ WARNING

If any of these conditions are not met,

the existing system must be updated or

replaced for that concern. Failure to

follow all instructions can result in flue gas

spillage and carbon monoxide emissions,

causing severe personal injury or death.

Check the following venting components before installing:

• Material - For materials listed for use with this appliance,

see Section 2 - General Venting. For polypropylene or

stainless steel venting, an adapter of the same

manufacturer must be used at the flue collar connection.

• Size - To ensure proper pipe size is in place, see Table 2A.

Check to see that this size is used throughout the vent

system.

• Manufacturer - For a stainless steel or polypropylene

application, you must use only the listed manufacturers

and their type product listed in Tables 2D and 2F for CAT

IV positive pressure venting with flue producing

condensate.

• Supports - Non-combustible supports must be in place

allowing a minimum 1/4" rise per foot. The supports

should adequately prevent sagging and vertical slippage,

by distributing the vent system weight. For additional

information, consult the vent manufacturer’s

instructions for installation.

• Terminations - Carefully review Sections 2 through 4 to

ensure requirements for the location of the vent and air

terminations are met and orientation of these fit the

appropriate image from the Sidewall or Vertical

options listed in the General Venting Section. For

stainless steel vent, only use terminations listed in Table

2F for the manufacturer of the installed vent.

• Seal - With prior requirements met, the system should be

tested to the procedure listed in parts (c) through (f) of

the Removal of an Existing Boiler Section on page 11.

With polypropylene and stainless steel vent, seal and connect

all pipe and components as specified by the vent manufacturer

used; with PVC/CPVC vent, see the Installing Vent or Air

Piping Section on page 19.