Lennox Hearth MODEL MONTAGE 32FS User Manual

Page 14

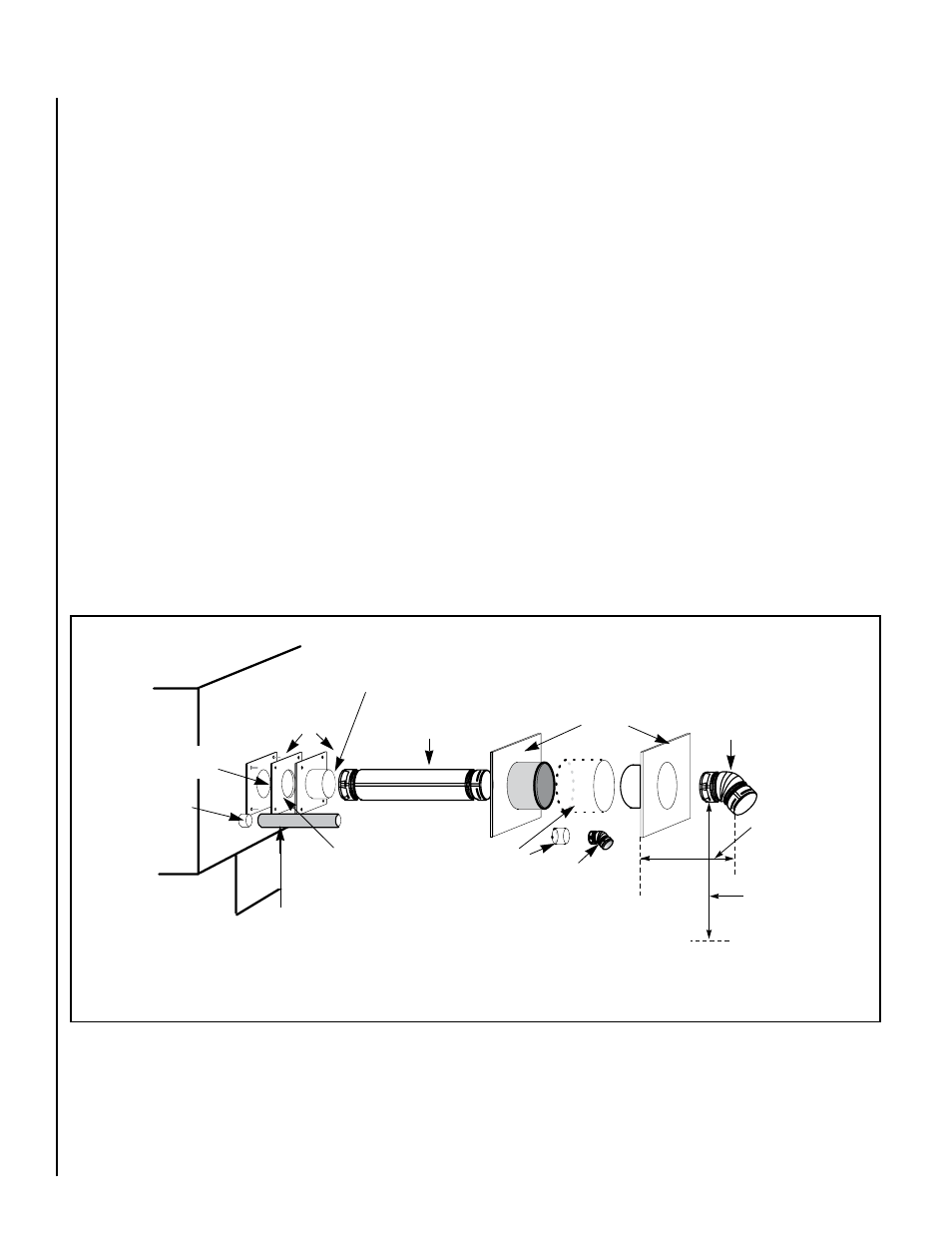

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE

14

Exhaust

Port

Quick

Disconnect

Straight “PL-vent”

Pipe

Combustion

Air Inlet

Collar

Metal Fresh

Air Pipe

Lytherm

Gasket

Wall

Thimble

45˚

Elbow

Holes through

the Wall for the

Thimble and

Fresh Air Pipe

45

o

Degree

Elbow Joint

for Fresh

Air Pipe

12” (305 mm)

Min. From

Outer Wall

12”(305 mm)

From

Ground or

Other Surface

Silicone sealant and 3 screws required on the first vent connection.

Secure and seal the remaining vent sections per vent manufacturers instructions.

Standard Horizontal Vent Installation

Installing Montage™ 3FS

This stove is approved for venting with Type L and Type PL pellet vent

pipe listed to UL 641 or ULC S609. We recommend the use of venting

products manufactured by Security Chimneys International.

1. Locate the proper position for the listed type “PL” wall thimble. Avoid

cutting wall studs when installing your pipe. Use a saber saw or keyhole

saw to cut the proper diameter hole through the wall to accommodate

the wall thimble. Use extreme caution to avoid cutting into power lines

within the wall of the home. The hole size will depend on the brand

of pellet vent that you are using. Install the wall thimble in the hole.

2. ALL INTERLOCKING PIPE CONNECTIONS MUST BE SEALED GAS-

TIGHT AND SECURED TOGETHER PER VENT MANUFACTURER

INSTRUCTIONS.

Position the stove approximately 12” (305 mm) from the wall on the

floor pad. Push the “PL” pipe through the wall thimble. Squeeze a

bead of high temperature silicone (RTV) sealer around the end of the

machined portion of the 3” (76 mm) pipe connector on the back of

the stove. Firmly push on a section of “PL” pipe until inner pipe liner

pushes into the bead of RTV sealer.

3. Push the stove with pipe attached towards the wall (the pipe will go

through the wall thimble). Do not position the back of the stove closer

than 2” (51 mm) from the wall (see Clearances, Page 5).

4. Install listed type “PL” 45 degree elbow with rodent screen or cap on

outside end of pipe. The Inlet shall remain free of obstruction while

unit is in operation and constructed in a manner so as to prevent

material from dropping into the inlet or into the area beneath the

dwelling. The inlet shall also have a screen with openings not larger

than 1/4" to prevent rodents from entering.

5. If the installation includes a source of outside combustion air; cut a

separate hole through the wall for the fresh air tube. This tube should

be 1-5/8” (42 mm) minimum diameter I.D., steel only. Connect outside

air pipe to air inlet on stove. This tube must be terminated with a 45

degree elbow or hood.

Notes:

• Combustion air may also be drawn from a vented crawl space under

the home.

• All joints for connector pipe are required to be fastened together per the

vent manufacturers instructions. If vented horizontally, joints must be

made gas-tight (air tight, sealed connection) in a manner as specified

on this page (see instruction #2). INSTALL VENT AT CLEARANCES

SPECIFIED BY THE VENT MANUFACTURER.

• Greater back clearance will improve the ease of serviceability of the

stove.

• The end of the exhaust pipe must extend a minimum of 12” (305 mm)

from the outside of the building.

Back of

Stove

Metal Fresh Air Pipe

OPTIONAL (EXCEPT FOR MOBILE HOME

INSTALLATIONS)

Figure 15 - Horizontal Vent Installation

Silicone sealant and three screws required on the first vent connection.

Secure and seal the remaining vent sections PER VENT MANUFACTURER INSTRUCTIONS.