Slant/Fin V-33 User Manual

Page 6

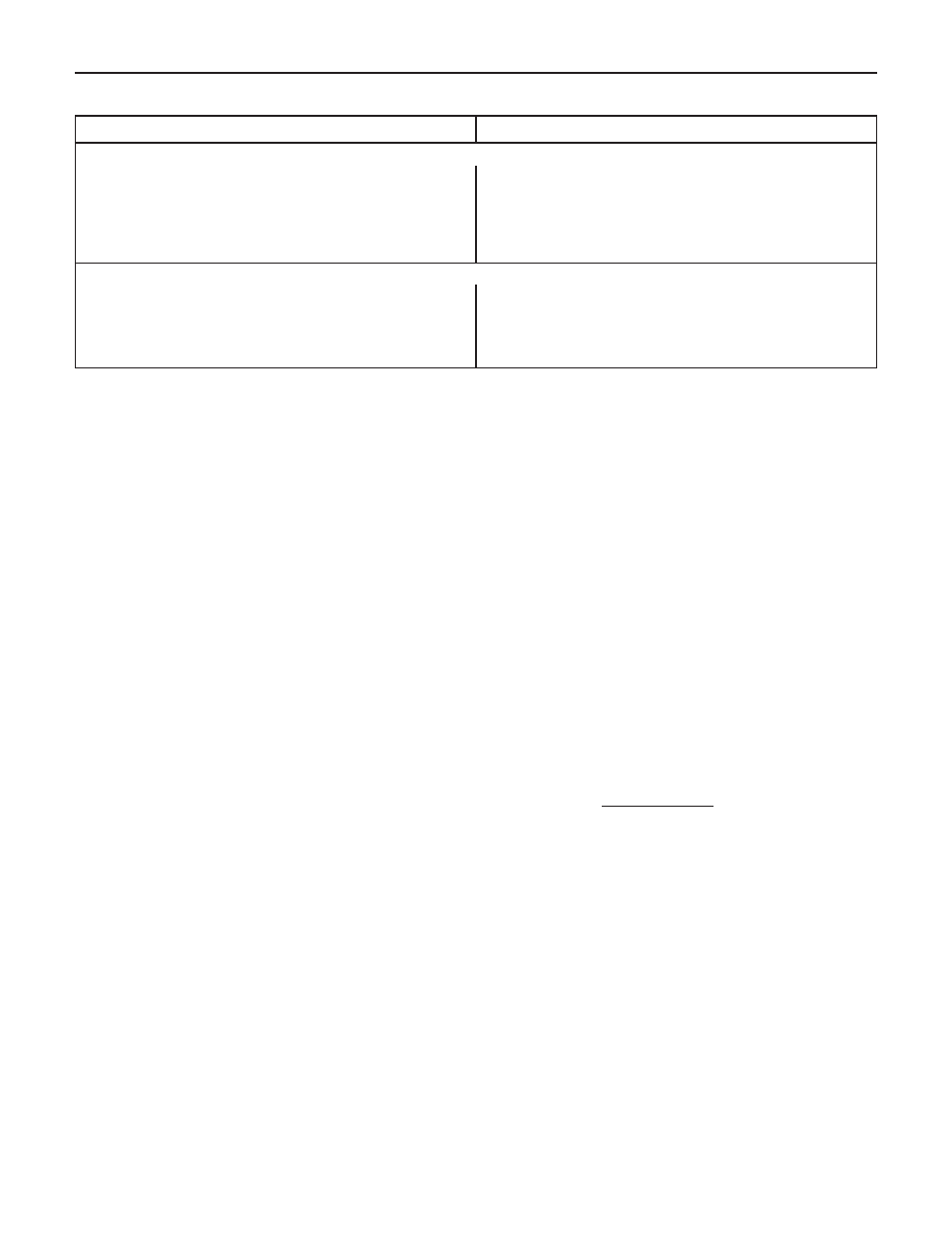

Model/Vent Size

V-90, V-120, V-150 and V-180 boilers may be vented into a

chimney (see “Chimney and type “B” venting” paragraph on

page 4) or into a type “B” vent, ONLY when converted to the

5" dia. Slant/Fin flue collar supplied unassembled with these

boilers and ONLY as described here, other places in this

booklet and in figures 6a and 6b.

V-33, V-60, V-90, V-120, V-150 and V-180 may be vented

horizontally and vertically ONLY when boilers are equipped

with the Slant/Fin factory installed 3" dia. flue collar and

adapter is used ONLY as described here, other places in

this booklet and figures 7, 8 and 9.

Requirements

Standard vent connector materials (i.e. galvanized or stain-

less steel vent pipe). Condensate drain and liquid tight seal

is required. See figures 6a, 6b and “Chimney and type “B”

venting” on page 4.

ONLY 3" dia. single wall Saf-T #AL 29-4C

▲

stainless steel

manufactured by Heat-Fab, Inc. may be used. Condensate

drain and liquid and pressure tight sealing is required. See

figures 7, 8, and 9.

6

V

ICTORY

The condensate drain should be installed as close to the

boiler as possible. The drain fitting size is 3/8" or

1/2"depending on the type of drain assembly. Clear plastic

tubing (3/8" I.D. or 1/2” I.D.) sized to fit the fitting must be

connected to the drain fitting. The clear tubing should be

formed into approximately a 4-5 inch diameter loop to form

a trap. The loop should be tied with cord or a cable tie

where the loop crosses over itself. See figures 6,7,8 and 9.

This loop should then be filled with water to form a liquid

filled trap. DO NOT OPERATE THE BOILER WITHOUT

INSTALLING THIS TRAP AND FILLING WITH WATER.

Periodic inspection should be made of this assembly for

deterioration of the tubing and to insure that the trap is not

plugged. If it is plugged or appears to have excessive

sediment in it, it should be removed from the drain assem-

bly, straightened out to clear the obstruction, reformed,

filled with water and reinstalled as before. The drain

should extend to a floor drain or to a plastic container

which will require emptying periodically.

D. WHEN VENTING HORIZONTALLY, COMMON VENTING

WITH OTHER APPLIANCES IS NOT ALLOWED.

VERTICAL PRESSURE VENTING

Vertical pressure venting (not natural draft chimney and type “B”

venting) is allowed with the 3" flue collar and adapter and #AL

29-4C

▲

stainless steel vent system previously shown in “Hori-

zontal Pressure Venting” paragraph No.1. This arrangement is

shown in Figure 9.

Note, that when using a 3" diameter vent for vertical pressure

venting, a chimney may be used as a chase for a vertical vent

(support is required in conjunction with firestop as per vent

manufacturers’ instruction). The 3" vent system MUST extend the

total length of the chimney but not longer than the equivalent

length limitations indicated on page 5 under “HORIZONTAL

PRESSURE VENTING” paragraph 2A. Other appliances can

NOT be vented into the same chimney.

As noted previously, all Victory boilers MUST be installed with a

condensate drain trap. Vent system must be sealed liquid and

pressure tight.

The instructions indicated in “HORIZONTAL PRESSURE VENT-

ING” on pages 5 and 6 must also be followed for the above

described Vertical Pressure Venting except, use figure 9 includ-

ing the clearances shown in figure 9 in place of figures 7 and 8.

REGULAR INSPECTION

A. Inspect the system regularly for condensation, corrosion

and/or physical damage. A qualified professional should service

the boiler annually and include such an inspection at that time.

The homeowner should look over the system monthly for dam-

age, water stains, any signs of rust, other corrosion or separation

of the flue (vent) tubing and fittings.

B. Should an inspection turn up signs of condensation, corrosion

or damage, the boiler should be shut down immediately and the

condition should be corrected by a qualified professional.

GAS PIPING

A. Local installation codes apply. The pipe joint compound used

on threads must be resistant to the action of liquefied petrole-

um gases.

B. The gas supply line to the boiler should be run directly from

the meter for natural gas or from the fuel tank for L.P. propane

gas. See page 2 for location of union and manual main shut-

off valve that may be specified locally.

Selecting pipe size for natural gas:

1. Measure or estimate the length of piping from the meter to

the installation site.

2. Consult gas supplier for heating value of gas (BTU/cu. ft.).

3. Divide boiler rated input by heating value to find gas flow

in piping (cu. ft. per hour).

4. Use table below to select proper pipe size.

Example: Boiler model V-150 is to be installed. Distance from

gas meter to the boiler is 30 ft. Heating value of natural gas is

1020 BTU/cu. ft. Select proper pipe size.

Gas flow =

150,000 BTU/hour

=

147 cu. ft. per hour

1020 BTU/cu. ft.

At 30 ft. length of pipe, match required capacity from table below

(choose higher capacity, in this case is 152 cu. ft. per hour).

Required pipe size is 3/4".

Improper gas pipe sizing will result in pilot flame outages, insuffi-

cient heat and other installation difficulties. For more information

and also if other appliances are to be attached to the piping sys-

tem, see Appendix C of National Fuel Gas Code ANSI Z223.1-

latest edition.

C. The boiler and its gas connection must be leak tested

before placing the boiler in operation. Use liquid soap

solution for all gas leak testing. DO NOT use open flame.

This boiler and its individual shutoff valve must be discon-

nected from the gas supply piping system during any

pressure testing of that system at test pressures in

excess of 1/2 PSIG.

This boiler must be isolated from the gas supply piping

system by closing its individual manual shutoff valve dur-

ing any pressure testing of the gas supply piping system

Figure 5.

▲

: AL 29-4C is a registered trademark of Allegheny Ludlum Corp.

NATURAL DRAFT CHIMNEY AND TYPE “B” VENTING

PRESSURE HORIZONTAL AND VERTICAL VENTING