Slant/Fin V-33 User Manual

Page 5

V

ICTORY

5

HORIZONTAL PRESSURE VENTING

All VICTORY models are certified for horizontal pressure

venting with the following restrictions:

1.

Vent Material

A. The vent system for horizontal venting must be UL list-

ed single wall Saf-T 3" diameter #AL 29-4C

▲

stainless

steel manufactured by Heat-Fab, Inc. The manufactur-

ers’ part numbers for various items of the vent system

are listed in SLANT/FIN Parts List, Publication # V-

10PL.

B. DO NOT use plastic or galvanized flue pipe.

C. For horizontal, through the wall venting, the 3" flue

collar and adapter MUST be used. The vent pipe size

must be 3" diameter from the boiler to the outside ter-

mination. Certain restrictions on the location of the

vent terminal are specified in APPENDIX "B" and must

be followed.

2

. Installation

A. Figures 7 and 8 show the allowed venting arrange-

ments. The maximum equivalent vent length is 40 feet

plus vent terminal for all models except V-180 which

has a 20 feet maximum equivalent vent length. Every

90° turn in the vent piping is equivalent to 5 feet of

straight run, (eg. a V-120 system with 3 elbows and the

outside terminal would allow 40 - 15 = 25 feet of

straight run). The minimum allowable equivalent vent

length is 2 feet and 1 elbow plus vent terminal for all

models, see table below. NOTE: For best operation,

elbows should be at least five diameters apart other-

wise maximum vent length should be reduced.

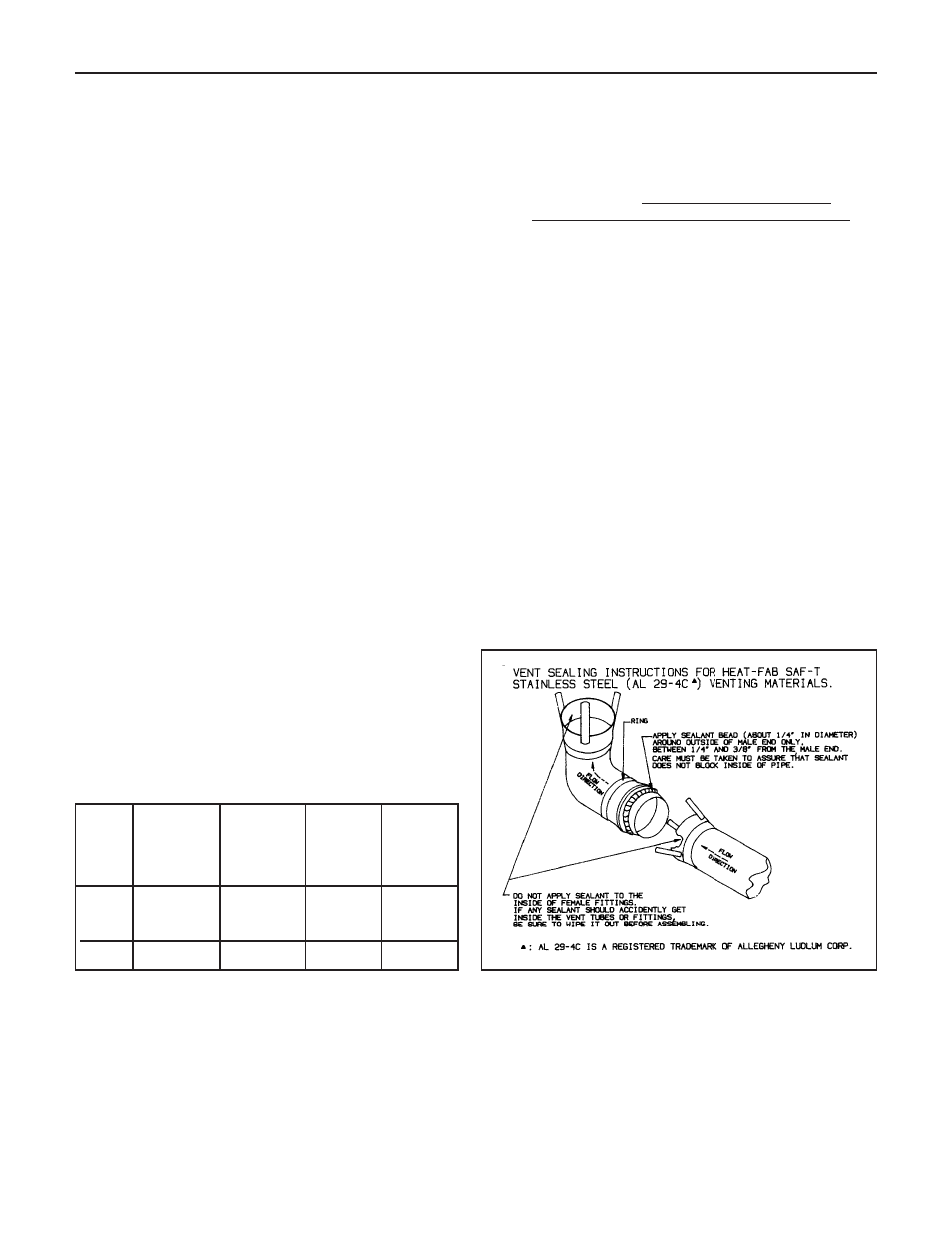

B. When joining the various components of the above list-

ed vent systems, the manufacturers’ instructions

should be closely followed to insure proper sealing.

Use GE-RTV 106 or Dow Corning 732 Sealant for

sealing of pipe and fittings. See figure 4 for proper

application of vent pipe sealant.

C. All Victory boilers require a condensate drain and drain

trap.

The horizontal pipe must be sloped TOWARD the con-

densate drain at least 1/4" per 1' of run. The horizontal

portion must also be supported with pipe straps at

intervals no greater than indicated by vent pipe manu-

facturer’s instruction.

Where the vent pipe goes through the outside wall, a

thimble must be used (see Figures 7 and 8).

Heat-Fab pipes and fittings

cannot be cut to length.

Use slip joint connector (Heat-Fab part no. 7324GC) to

adjust pipe lengths dimensions.

Figure 4.

Vent Sealing Instructions

(Consult vent manufacturer’s instructions.)

3” Diameter Venting System Restrictions

Model

Minimum

Length*

Maximum

Equivalent

Length

including

Elbows*

Equivalent

Length

of Elbows

Minimum

No. of

Elbows*

V-33

to

40 ft.

5 ft.

2 ft.

1

V-150

V-180

20 ft.

5 ft.

2 ft.

1

* Vent terminal is in addition to the allowed vent pipe length and elbows.

▲

: AL 29-4C is a registered trademark of Allegheny Ludlum Corp.