Slant/Fin V-33 User Manual

Page 14

14

V

ICTORY

2. Safety Shutdown Checkout

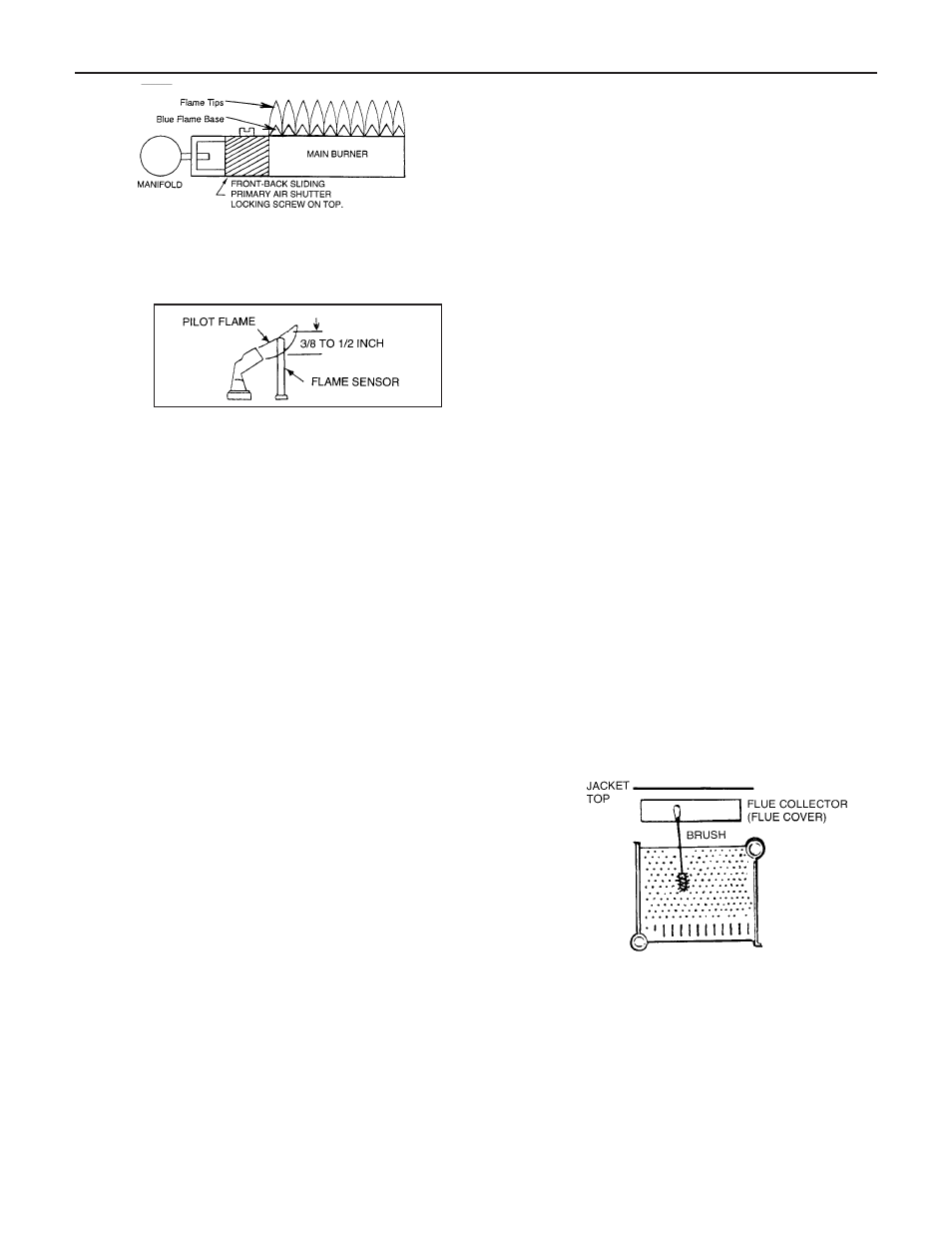

a. For proper operation the pilot should engulf the

thermocouple, powerpile generator or flame sen-

sor as shown below.

b. To adjust pilot, turn pilot flow adjustment screw

on valve clockwise or counterclockwise to give a

steady flame enveloping 3/8 to 1/2 inch of the tip

of the thermocouple, generator or flame sensor.

Note that turning the pilot adjust screw clockwise

will decrease the pilot flame.

c. Check safety shutdown of gas valve by following

procedure outlined "CARE" and "MAINTE-

NANCE" section, item IV-3 in this booklet.

CARE AND MAINTENANCE

WARNING: THE FLOW OF COMBUSTION AND VENTILAT-

ING AIR TO THE BOILER SHOULD NOT BE OBSTRUCTED.

This section must be brought to the attention of the owner by

the installer so that the owner can make the necessary

arrangements with a qualified service agency for the periodic

care and maintenance of this boiler. The installer must

inform the owner that the gas supplier can recommend a

number of qualified service agencies. The installer must also

inform the owner that the lack of proper care and mainte-

nance of this boiler and any fuel burning equipment may

result in a hazardous condition.

1. GENERAL MAINTENANCE (Refer also to Owner’s Infor-

mation Manual)

These operations are recommended to be performed at

regular intervals:

A. BOILER HEATING SURFACES: clean off all coatings

found.

B. BOILER CONTROLS: check contacts, settings, cor-

rect functioning.

C. PIPING: check piping and accessories for leaks.

D. CHIMNEY VENTING SYSTEM: check for obstructions

and leaks. If the boiler is vented horizontally through

the wall, the outside termination elbow and screen

should be checked for any debris blocking the opening

and cleaned as required.

E. BOILER ROOM AIR SUPPLY: check air vents for con-

tinued POSITIVE supply of air as required. Air needs

are greatest in cold weather. Air vents must be open

and free of obstruction.

F. WATER SYSTEM: check

1. System to be full of water, and pressure to remain

stable at correct setting on gauge.

2. Air-control system: noise and air binding in radiation

should not occur.

3. Water lines: slightest leaks should be corrected.

4. Low water cutoff, for operation (see instructions fur-

nished with unit).

II. WATER LEVEL CHECK DURING HEATING SEASON:

A. Check water pressure regularly and add water slowly

to system when needed.

If much water is added,

venting may be necessary.

B. Regular loss of water from water boiler system may

indicate either a system leak, or a faulty air control

system, or a faulty automatic fill valve.

III. ANNUAL INSPECTION AND CLEANING:

A. It is important that this boiler be inspected by a

competent serviceperson to help insure safe and

reliable operation.

B. Check for gas leaks from valve and gas piping to

burners and pilot. If leaks are found, repair or replace

as required.

C. This inspection should include:

1. Controls check. See SAFETY CHECK, IV.

2. Recheck of input gas rate to burners. See "Initial

Start" paragraph in "Operating Instructions" section.

3. Re-adjusting for best flame characteristics of main

flame and pilot(s).

See "Initial Start" paragraph in "Operating Instruc-

tions" section and see "Burner Adjustment" section.

4. Burner and boiler flue passage cleanliness:

BURNER AND FLUE CLEANING (see sketch). It is

suggested that paper be placed on burners to col-

lect any foreign material in cleaning flues.

5. Remove jacket top and flue cover. Remove inducer

assembly.

6. Use wire brush to clean flueways.

7. Replace flue cover and re-seal with furnace

cement. Replace jacket top. Remove and dispose

of paper and accumulated material. Replace

inducer assembly. To prolong life of motor, lubricate

with 6 drops of Anderol 465 annually.

8. If burner surfaces are not clean, or if uneven flame

indicates plugged burner ports, remove and

clean burners.

NOTE–TO REMOVE BURNERS:

1. Disconnect pilot at pilot mount, or disconnect

pilot gas line at gas valve, before removing burn-

ers next to pilot.

2. Lift burner and remove burner from orifice.

3. Clean and replace burners* and pilot. Adjust