Creating project files—plc to devices – Siemens DTU3005-B User Manual

Page 30

4

Creating Project Files—PLC to Devices

26

Siemens Energy & Automation, Inc.

parameter is used only with Allen-Bradley PLCs. It

specifies the file number in the PLC that contains the

register values that are transferred to or from the

device.

4.

Select Save to save the information to the project file,

and then select Ok or press Esc to exit the device

diagnostic registers screen. If at any time you want to

return to the last saved version of the device diagnos-

tics registers, select Revert without saving any

changes.

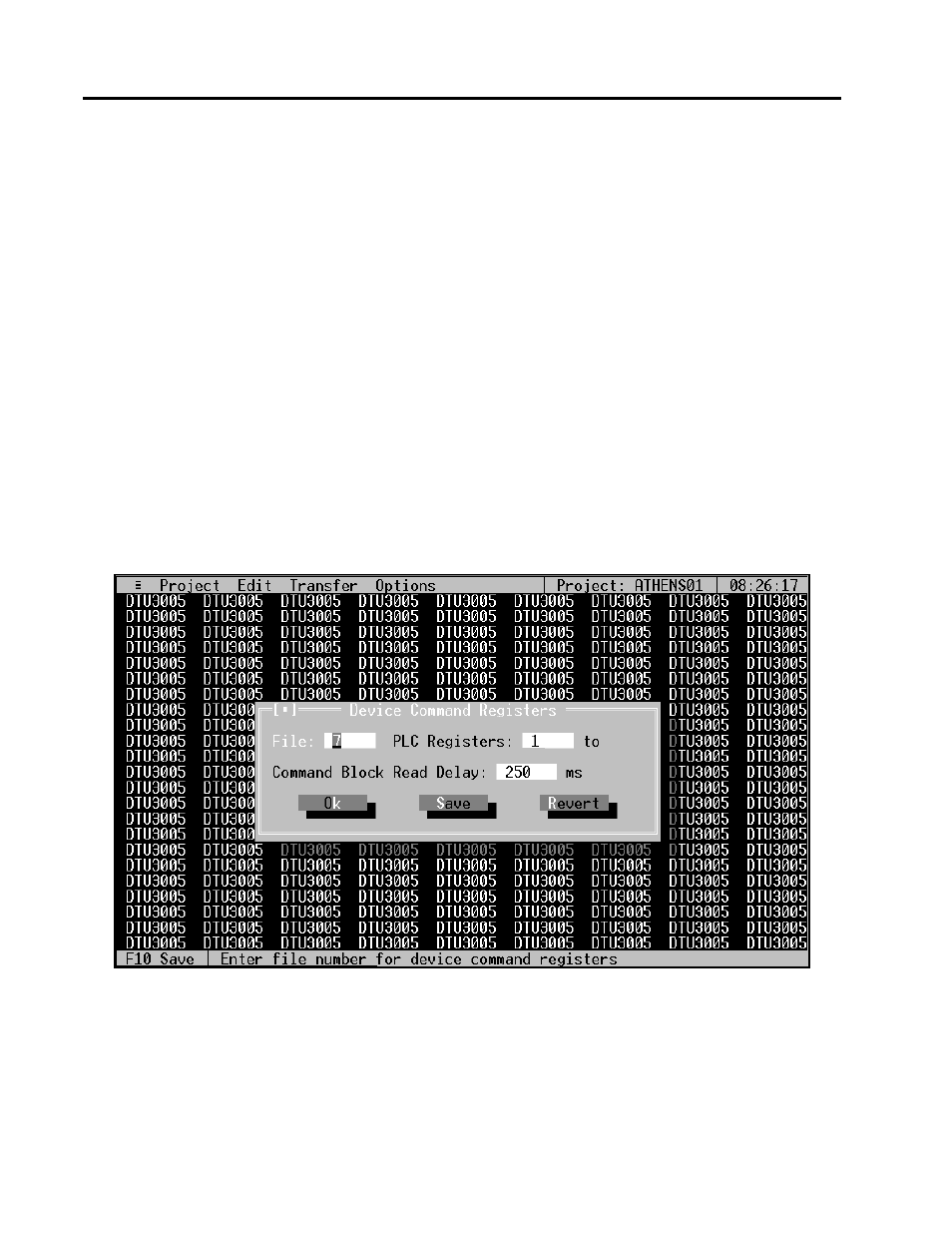

4.11

Device Command Registers

The device command registers consist of two consecutive

registers for each device entered in the device list. These

registers allow the PLC to transmit commands to each of

the devices. To send a command, all the PLC needs to do is

to place the command values into the appropriate PLC reg-

isters, which the DTU3005B unit reads and then processes.

The first register contains the command, and the second

register contains the data associated with the command.

The format of the command registers for each device are

described in Appendix E. All the command registers are

placed in contiguous locations in the PLC’s registers and

are assigned by the DTU3005 to each device in the order

that they are listed in the device list.

To use the command registers for a particular device, the

PLC program must do the following, in order:

1.

First, set the command word to 0 or -1 (FFFF hexadec-

imal).

2.

Set the data word to the appropriate value.

3.

Set the command word to the appropriate value.

4.

After the command is set the PLC must wait for the

DTU3005B unit to change the command word to either

0 (to indicate successful processing of the command),

or -1 (to indicate an error).

To indicate the location of the command registers on the

PLC, follow these steps:

1.

Select Device Command Registers from the Edit

menu. The Device Command Registers screen

appears:

2.

Enter the starting register address in the PLC Regis-

ters field. The DTU3005 Editor software will determine

the proper number of registers for the number of

devices entered in the device list and indicate the final

register number. These registers must be different from

those used for device data and diagnostics. Refer to

Appendix A for a list of valid register numbers for your

PLC. Failure to use different register addresses will

cause communication errors, and may cause unex-

pected operation of the devices.

3.

Press Shift+Tab, or click the left mouse button to high-

light the File field and enter the file number. This

parameter is used only with Allen-Bradley PLCs to

specify the file number in the PLC that contains the reg-

ister values that are transferred to or from the device.