J Page 63

Df[\cN(/)+('?pYi`[KXYc\JXn

-61-

J

M

@:<

The trunnion and motor assembly could fall and crush

your hands or arms if the trunnion mounting cap

screws are loosened too much during the following

steps. DO NOT remove the cap screws that secure

the trunnions to the table or loosen them more than

1

1

⁄

2

turns!

7. To adjust the table, loosen the two cap screws that

secure the rear trunnion to the underside of the

table 1–1

1

⁄

2

turns (see Figure 96), and slightly tap

the trunnion with the dead blow hammer in the

needed direction.

8. Tighten the two cap screws, then repeat Steps 2–5

to re-check the slot-to-blade parallelism.

— If the measurement is the same from front-to-

back, skip ahead to Step 11.

— If the adjustments you made in Step 7 were not

enough to adjust the miter slot parallel to the

blade, continue to Step 9.

9. Loosen the two cap screws that secure the front

trunnion to the underside of the table (see

Figure 97) and tap the trunnion in a similar manner

as you did in Step 7.

10. Tighten the two cap screws and recheck the miter

slot-to-blade parallelism.

— If the blade tip measurement is the same on both

sides, continue to Step 11.

— If the adjustments you made in Step 9 were not

enough to adjust the miter slot parallel with

the blade, continue adjusting the front and rear

trunnions as needed until the miter slot and blade

are parallel.

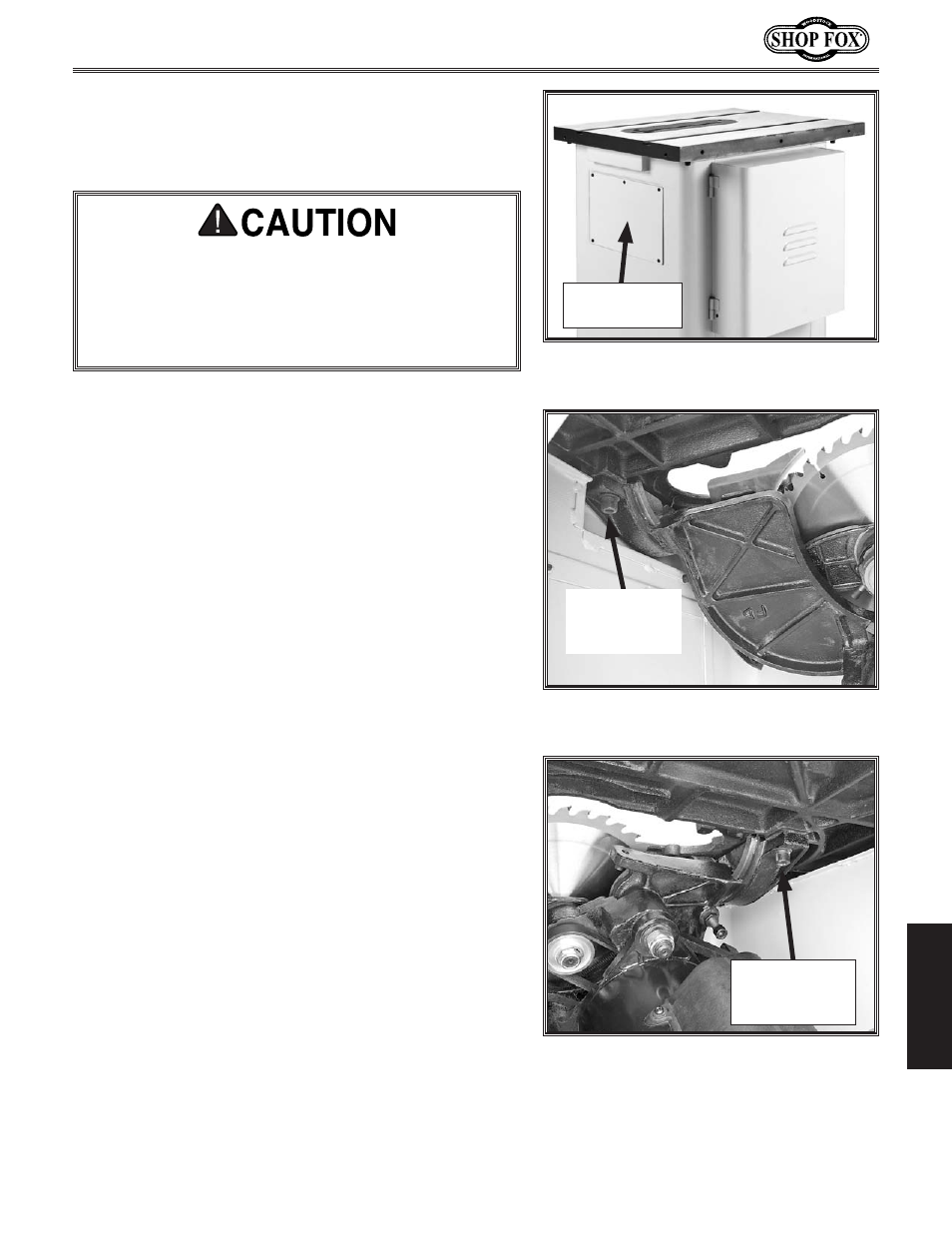

Figure 95. Location of the rear trunnion

access panel.

Rear Trunnion

Access Panel

Figure 96. Location of the rear trunnion

cap screw (1 of 2).

Rear Trunnion

Cap Screw

(1 of 2)

6. Remove the six button head cap screws that secure

the rear trunnion access panel (see Figure 95), then

remove the panel and open the motor access cover

to reach the trunnions.

Figure 97. Location of the front trunnion

cap screw (1 of 2).

Front Trunnion

Cap Screw

(1 of 2)