Blade guard assembly – Woodstock SHOP FOX W1824 User Manual

Page 30

Df[\cN(/)+('?pYi`[KXYc\JXn

-28-

FG

<

I

8

K@FEJ

Blade Guard Assembly

The term "blade guard" refers to the assembly that

consists of the clear polycarbonate shield, the spreader,

and the anti-kickback pawls on each side of the spreader

(see Figure 37). Each of these components have

important safety functions during the operation of the

saw.

Guard

The clear polycarbonate guard allows the operator to

see the blade cut the workpiece during operation. This

guard is designed to lift as the workpiece is pushed into

the blade and remain in contact with the workpiece

throughout the entire cut.

The guard reduces injury risk by providing a barrier

around the blade that prevents accidental contact and

contains flying wood chips.

To ensure that the guard does its job effectively, the

guard must always be in the downward position against

the table during idle operation, and the hinge mechanism

must be maintained in good working condition so the

guard can freely pivot up and down to accommodate the

height of the workpiece and return to the table surface.

Spreader

The spreader is a metal plate that prevents the freshly

cut pieces of the workpiece from pinching the backside of

the blade and causing a kickback. It also acts as a barrier

behind the blade to shield hands from being pulled into

the blade if a kickback occurs.

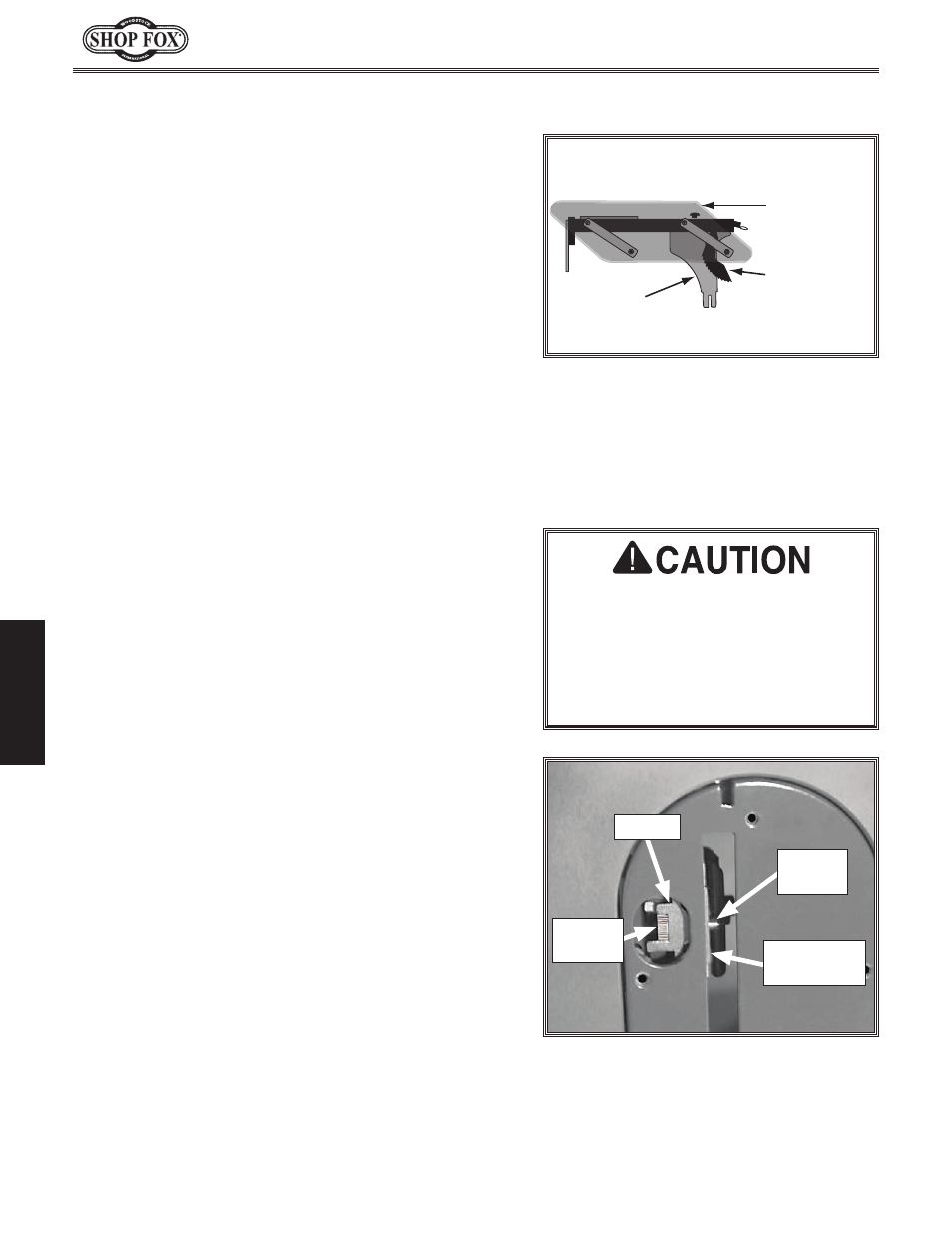

Blade Guard & Spreader Installation

1. DISCONNECT SAW FROM POWER!

2. Install the standard table insert.

3. Slide the knurled knob out (see Figure 38), then

rotate it so it engages the upper bracket.

4. Slide the blade guard spreader all the way down

into the adjustment block, then rotate the knurled

knob so it disengages the bracket and the locking pin

engages the hole in the center of the spreader.

5. Tug the spreader upward to verify that it is locked

and does not come out when pulled.

Clear Guard

Anti-Kickback

Pawl

Spreader

Figure 37. Blade guard assembly

components.

In order to work properly, the spreader

cannot be bent or misaligned with the

blade. If the spreader gets accidentally

bent, take the time to straighten it

or just replace it. Using a bent or

misaligned spreader will increase the

risk of kickback!

Figure 38. Knurled knob used to secure

the spreader.

Knurled

Knob

Bracket

Locking

Pin

Adjustment

Block