Push sticks, Making a push stick, Fg < i 8 k@fej – Woodstock SHOP FOX W1824 User Manual

Page 49

Df[\cN(/)+('?pYi`[KXYc\JXn

-47-

FG

<

I

8

K@FEJ

Push Sticks

When used correctly, push sticks reduce the risk of injury

by keeping hands away from the blade while cutting. In

the event of an accident, a push stick can absorb damage

that would have otherwise happened to hands or fingers.

Use push sticks whenever your hands will get within 12"

of the blade. To maintain control when cutting large

workpieces, start the cut by feeding with your hands then

use push sticks to finish the cut, so your hands are not on

the end of the workpiece as it passes through the blade.

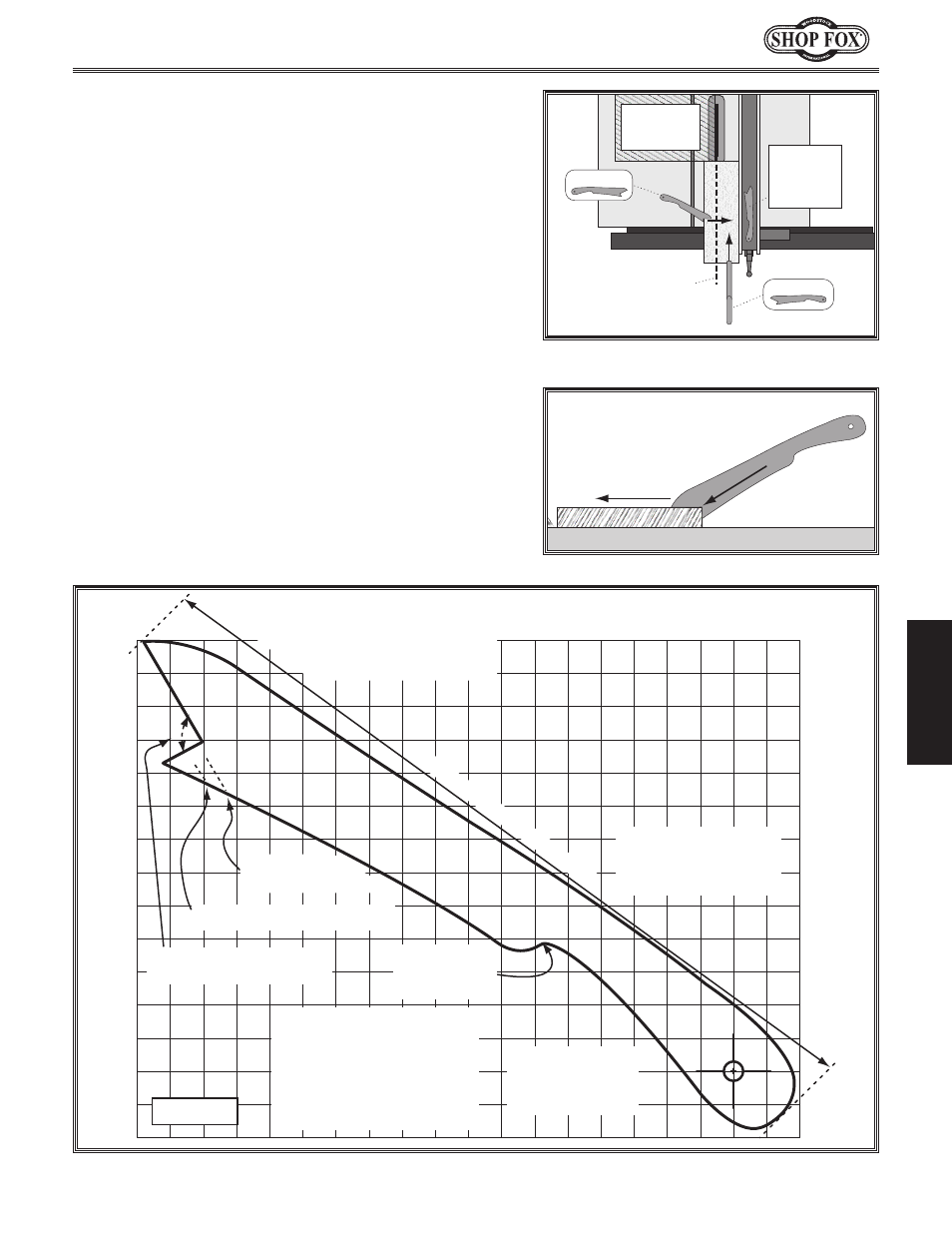

Feeding: Place the notched end of the push stick

against the end of the workpiece (see inset Figure 69),

and move the workpiece into the blade with steady

downward and forward pressure.

Supporting: A second push stick can be used to keep the

workpiece firmly against the fence while cutting. When

using a push stick in this manner, only apply pressure

before the blade; otherwise, pushing the workpiece

against or behind the blade will increase the risk of

kickback (see Figure 69).

90º

Cut here to

push

1

⁄

4

" stock

Cut here to push

1

⁄

2

" stock

Notch for placing on

corners of workpieces

15

3

/

4

" Minimum Length

MATERIAL: Only use hard-

wood, sturdy plywood, or

high-density plastic. Do not

use softwood that may break

under pressure or metal that

can break teeth from the

blade!

SANDING: Sand

edges to remove

rough edges and

increase comfort.

SIZING: Push stick must

be at least 15

3

⁄

4

" long.

Use

1

⁄

2

"–

3

⁄

4

" thick

material.

Notch to help

prevent hand

from slipping

1

⁄

2

" Grid

Figure 71. Template for a basic shop-made push stick (not shown at actual size).

Making a Push Stick

Use this template to make

your own push stick.

=`^li\.'% Side view of push stick in-use.

Feeding

Supporting

Blade

Path

Push Stick

Push Stick

Push Stick

Prohibition

Zone

Store Push

Stick Here

for Easy

Access

=`^li\-0% Using push sticks to rip narrow

stock.