Miter slot to blade parallelism – Woodstock SHOP FOX W1824 User Manual

Page 62

Df[\cN(/)+('?pYi`[KXYc\JXn

-60-

J

M

@:<

Miter Slot to Blade

Parallelism

Your table saw will give the best results if the miter slot

and the rip fence are adjusted parallel to the blade. If

either of these are not exactly parallel, your cuts and

your finished work will be lower in quality, but more

importantly, the risk of kickback will be increased.

Tools Needed

Qty

Adjustable Square ..............................................1

Marker ............................................................1

Dead Blow Hammer.............................................1

Hex Wrenches 3, 8 mm ................................. 1 Each

To adjust the blade parallel to the miter slot, do these

steps:

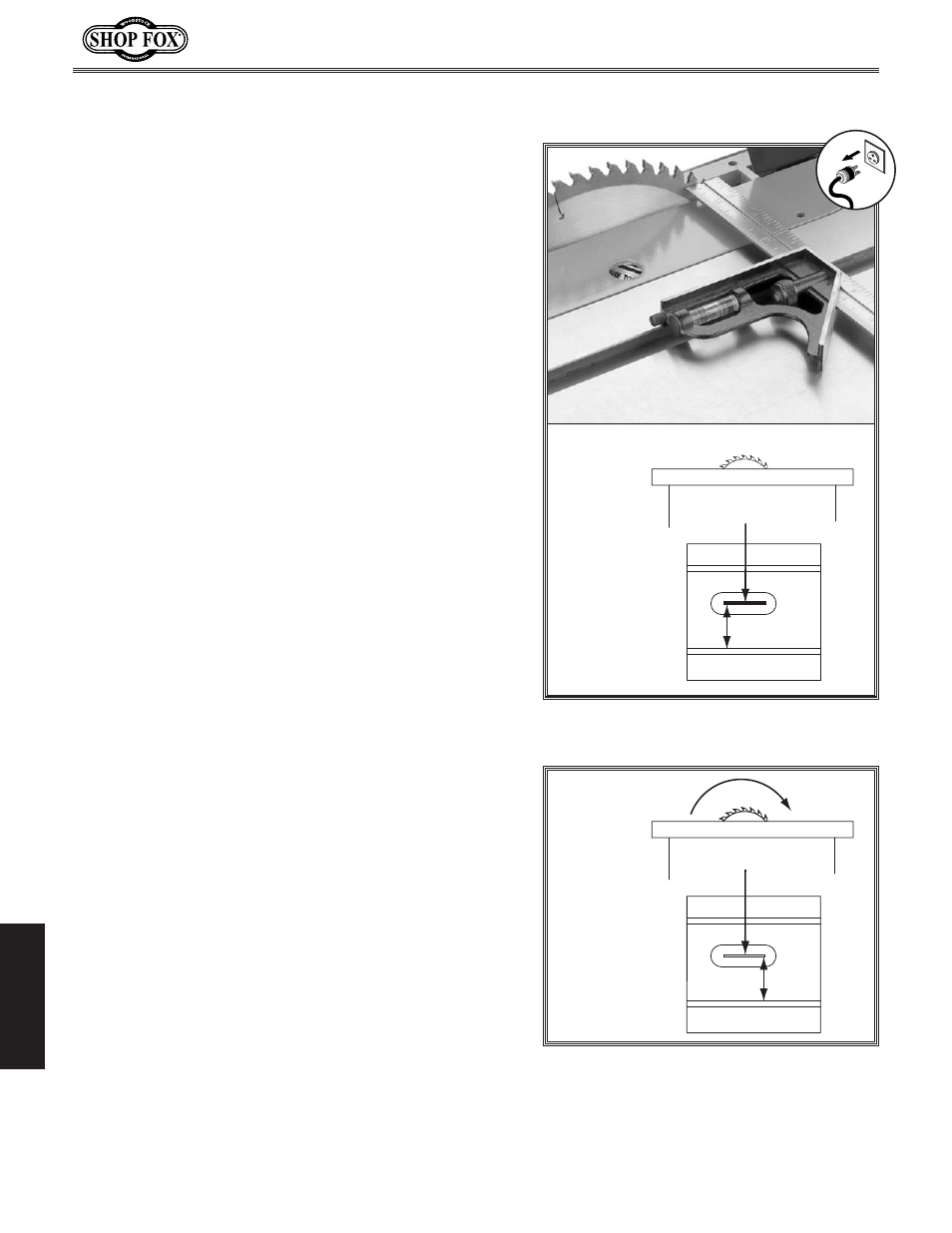

1. DISCONNECT SAW FROM POWER!

2. Use the adjustable square to measure the distance

from the miter slot to a carbide tip on the blade, as

shown in Figure 93. Make sure that the face of the

adjustable square is even along the miter slot.

3. With the end of the adjustable square just touching

the carbide tip, lock the measurement bar of the

square in place. Now, mark the tip of the carbide tip

with a marker where you made this measurement.

4. Rotate the marked blade tip to the other end of the

table insert.

5. Slide the adjustable square down to the other end

of the table insert, and compare the distance from

the marked blade tip to the end of the adjustable

square, as shown in Figure 94.

— If the blade tip measurement is the same on both

sides, go to Step 11.

— If the blade tip does not touch the end of the

adjustable square in the same manner as in the

first measurement, the table will need to be

adjusted. Proceed to Step 6.

Figure 93. Making the first slot-to-blade

measurement at 90°.

Blade tilted to 90º

Front

STEP A

A

Blade tilted to 90º

Front

B

STEP B

Figure 94. Making the second slot-to-blade

measurement at 90°.