Schedule, Lubrication – Grizzly G0704 User Manual

Page 38

-36-

Model G0704 (Mfg. Since 08/11)

SEcTION 6: MAINTENANcE

Always disconnect power

to the machine before

performing maintenance.

failure to do this may

result in serious person-

al injury.

For optimum performance from your machine,

follow this maintenance schedule and refer to any

specific instructions given in this section.

Daily check:

•

make sure mill/drill is disconnected from

power when not in use.

•

Check for loose mounting bolts.

•

make sure mill/drill is clean and lubricated.

•

Check for worn or damaged wires.

•

Check for any other unsafe condition.

Monthly check:

•

Check that gibs are adjusted properly.

biannual check:

•

lubricate headstock lead screw and gears.

Schedule

regular lubrication will ensure your mill/drill per-

forms at its highest potential.

regularly wipe all

sliding surfaces with primrose

®

Way oil (

page 34)

or a light machine oil, then move the components

back and forth several times to ensure smooth

movements (

figures 46–48). every six months,

or more often with heavy use, clean and lubricate

the leadscrews and vertical handwheel ring & pin-

ion gears, as outlined on

page 38.

protect other unpainted cast iron surfaces with

regular applications of products like g96

®

gun

treatment, slipit

®

, or boeshield

®

t-9.

Lubrication

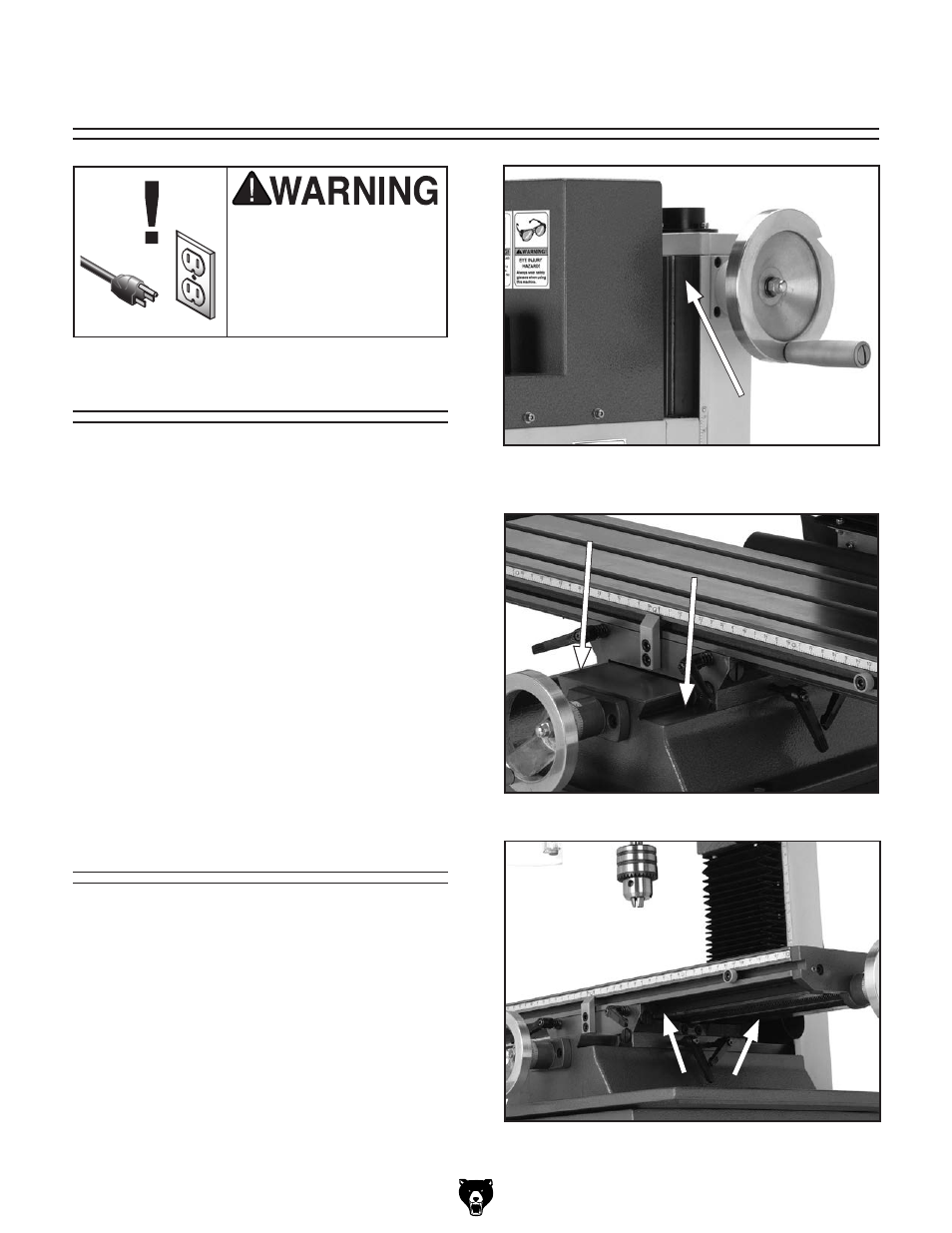

figure 46. vertical way lube location (both

sides).

figure 47. Cross way lube locations.

figure 48. longitudinal way lube locations.