Test run & spindle break-in, Notice – Grizzly G0704 User Manual

Page 23

Model G0704 (Mfg. Since 08/11)

-21-

Test Run & Spindle

break-in

the model g0704 spindle speed can be set from

50–2250 rpm. you must follow the proper break-

in procedures to ensure the spindle bearings

break-in and seat before putting any milling load

on the machine.

To test run and break-in the spindle bearings:

1.

do all lubrication procedures highlighted in

Lubrication

in Section 6: MAINTENANcE

on

page 36.

2. make sure there are no obstructions around

or underneath the spindle.

3. place the spindle direction selection knob in

the "0" (oFF) position and press the emer-

gency stop button (

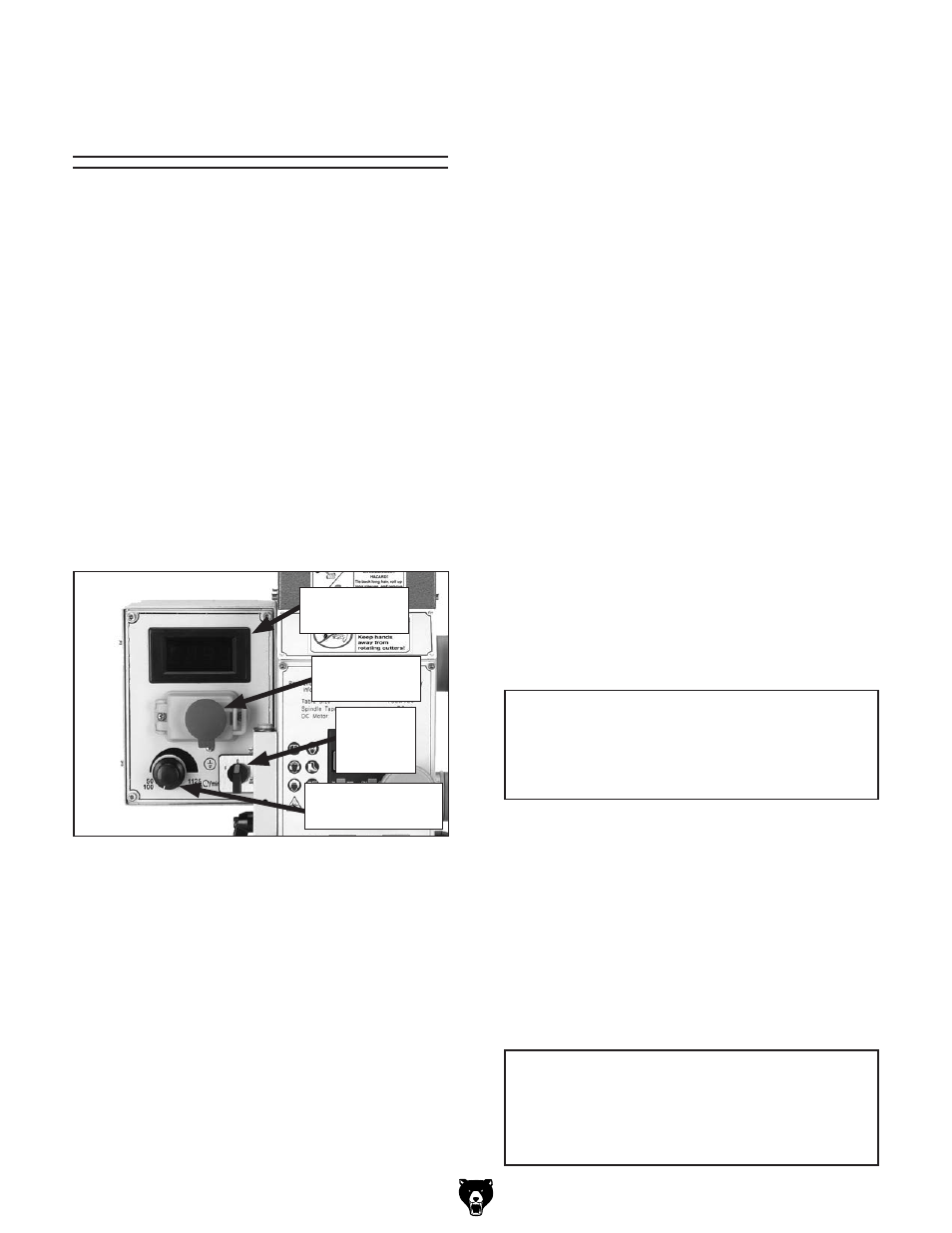

figure 17)

figure 17. test run controls.

4. Connect the mill/drill to the power source.

5. turn the speed range selector knob to the

"l" (low) position (

figure 1 on page 3) and

rotate the variable spindle speed knob all the

way to the left (slowest) position.

6. place the spindle direction knob in the "F"

(Forward) position. squeeze the tab on the

emergency stop button, pull it open, then

press the green button. the spindle will begin

to turn at a low rpm.

emergency

stop button

variable spindle

speed Knob

spindle

direction

Knob

spindle rpm

readout

failure to follow start up and spindle break-

in procedures will likely cause rapid deteri-

oration of spindle and other related parts.

NOTICE

10. increase the speed to 1000 rpm and let it

run for another ten minutes.

11. increase the speed to 2200 rpm and let it

run for another ten minutes.

12

. turn the mill/drill OFF.

13. set the spindle to rotate in the opposite direc-

tion, then press the green button and let it run

at 1000 rpm for another ten minutes.

DO NOT leave the area while break-in pro-

cedure is under way. you must be ready to

stop the machine if a problem occurs.

NOTICE

—When operating correctly, the machine

runs smoothly with little or no vibration or

rubbing noises.

— investigate and correct strange or unusual

noises or vibrations before operating the

machine further. always disconnect the

machine from power when investigating or

correcting potential problems.

7. press the emergency stop button. the

machine should stop.

—if the machine does stop, the emergency

stop button safety feature is working cor-

rectly. Continue to

Step 8.

—if the machine does not stop, the emer-

gency stop button safety feature is not

working correctly. this safety feature must

work properly before proceeding with regu-

lar operations. Call tech support for help.

8. open the emergency stop button cover and

press the green button to start the spindle.

9. While watching the spindle rpm readout,

turn the variable spindle speed knob until the

mill/drill reaches approximately 600 rpm,

then let it run for a minimum of 10 minutes.