Replacement – Graco ULTRA AIRLESS 230-963 User Manual

Page 26

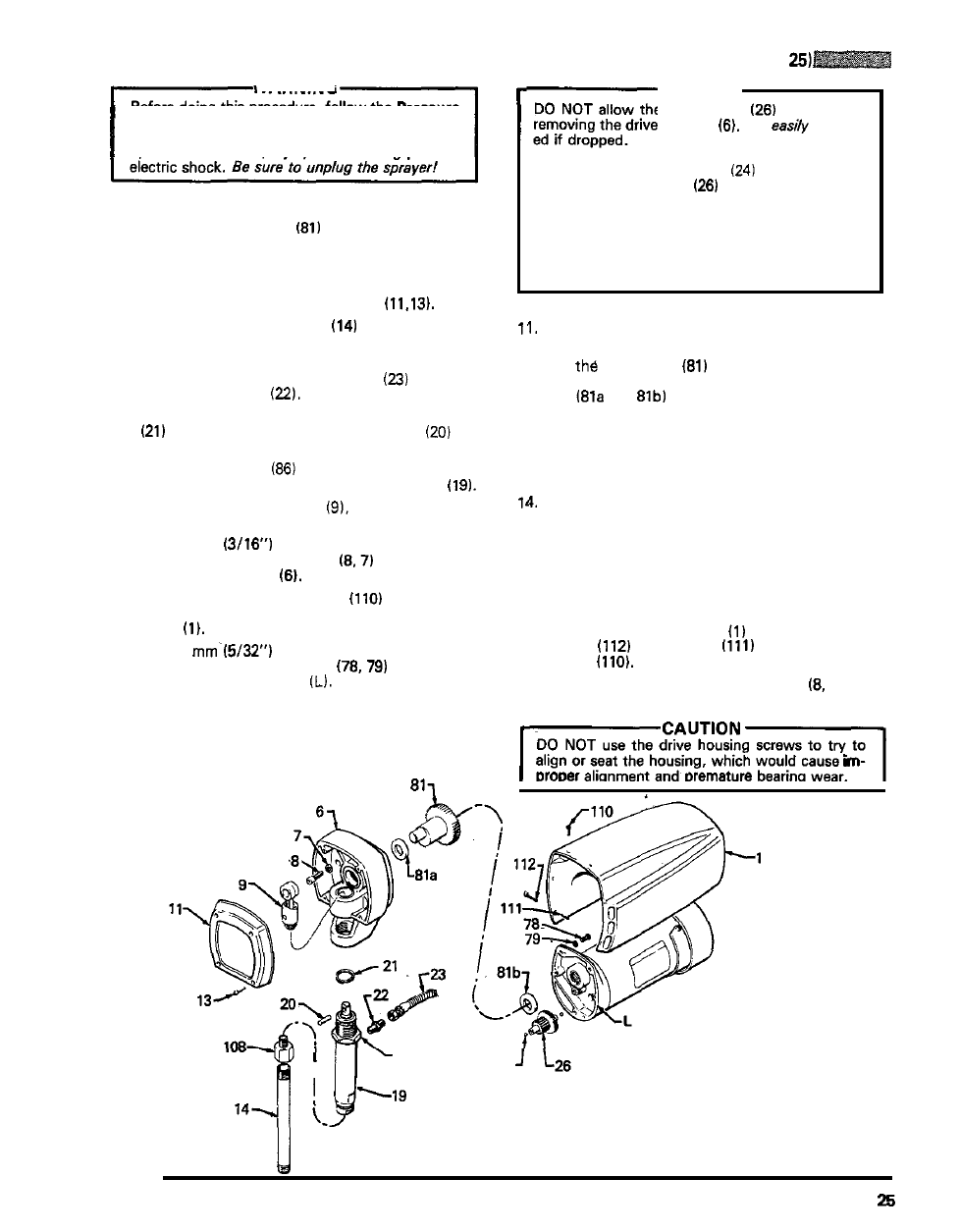

CONNECTING ROD, DRIVE HOUSING, or CRANKSHAFT REPLACEMENT

(See Fig

WARNING

Before doing

this

procedure, follow the Pressure

the risk of a fluid injection injury, splashing in the

Relief Procedure Warning on page

17 to reduce

eyes or on the skin, injury from moving parts or

NOTE:

Stop the sprayer at the bottom of its stroke

to get the crank

in

its lowest position. If

the crank must be lowered manually,

carefully rotate the blades of the fan with a

screwdriver.

1. Remove the front cover and screws

2.

Unscrew the suction tube

from the pump,

the pump from loosening.

holding a wrench on the pump intake valve to keep

3. Disconnect the pump outlet hose

from the

pump outlet nipple

4. Use a screwdriver

to

push aside the retaining spring

at the top of the pump. Push the pin

out

the rear.

5.

Loosen the jam nut

with an adjustable wrench.

Unscrew and remove the displacement pump

6.

Remove the connecting rod

inspect for wear or

damage, and replace if needed.

7. Use a

5

mm

hex key wrench to remove the

three screws and lockwashers

from the recess

of the drive housing

8.

Remove the four short screws

and

two

long

screws

(1121 and spacers (1111 from the motor

shield

Remove the shield.

9. Use a 4

hex key wrench to remove the

two

screws and lockwashers

from the top

rear of the front end bell

10. Lightly tap the lower rear of the drive housing with

a plastic mallet to loosen

it

from the motor front end

bell. Then pull the housing off.

CAUTION

DO

NOT allow the gear cluster

to fall when

removing the drive housing

It

is

damag-

ed if dropped.

DO NOT lose the thrust balls

located at each

end of the gear cluster

or allow them to fall

between gears. The ball, which is heavily covered

with grease, usually stays

in

the shaft recesses,

and not removed, the balls

will seriously damage

but could be dislodged. If caught between gears

the drive housing. If the balls are not

in

place, the

bearings will wear prematurely.

Inspect the drive housing for wear or damage and

replace if needed.

12. Pull

Crankshaft

out. Inspect for wear or

damage and replace, if needed. Be sure the bear-

ings

and

are

in

place on either side of the

crankshaft assembly.

13. Evenly lubricate the inside of the bronze bearing

in

the drive housing with high quality motor oil.

Liberally pack the roller bearings and gears with

bearing grease.

Install the crankshaft, meshing the gears.

15. Clean the mating surfaces of the drive housing and

front end bell.

16.

Carefully align the drive housing and front end bell

with the locating pins, then push the drive housing

onto the front end bell or tap

it

into place with a

plastic mallet.

17. Reinstall the motor shield

using the two long

screws

and spacers

and the four short

screws

18. Install the screws and lockwashers

7) and

tighten evenly.

DO

NOT use the drive housing screws to

try

to

align or seat the housing, which would cause

alionment and

bearina wear.

86

24

I

Fig

2 5

307-671