Graco 226-167 SERIES"A" User Manual

Gallon, Hydra-spray, Form

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

I N S T R U C T I O N S

A N D P A R T S L I S T

FORM:

306-704

P U B L . S H £ D : / - £ /

10

GALLON

PRESIDENT

HYDRA-SPRAY

UNITS

STATIONARY MODEL

PORTABLE MODELS

LESS WHEELS AND SRAKC

WITH MANUAL ELEVATOR

226-161 SERIES "A"

HAS MANIFOLD

WITH DUMP VALVE

WITH MANUAL ELEVATOR

WITH PNEUMATIC ELEVATOR

226-163 SERIES"A"

HAS MANIFOLD

WITH DUMP VALVE

226-165 S£R1ES"A"

HAS FILTER

WITH DUMP VALVE

226-167 SERtES"A"

HAS FILTER WITH DUMP

VALVE AND SURGE TANK

TIP OF

CUSTOMERS CHOICE

PNEUMATIC

ELEVATOR

r*

~

N.BT.

^

AIR INLET

MANUAL

ELEVATOR

I"

^N.RT.

AIR INLET

TIP OF

CUSTOMERS CHOICE

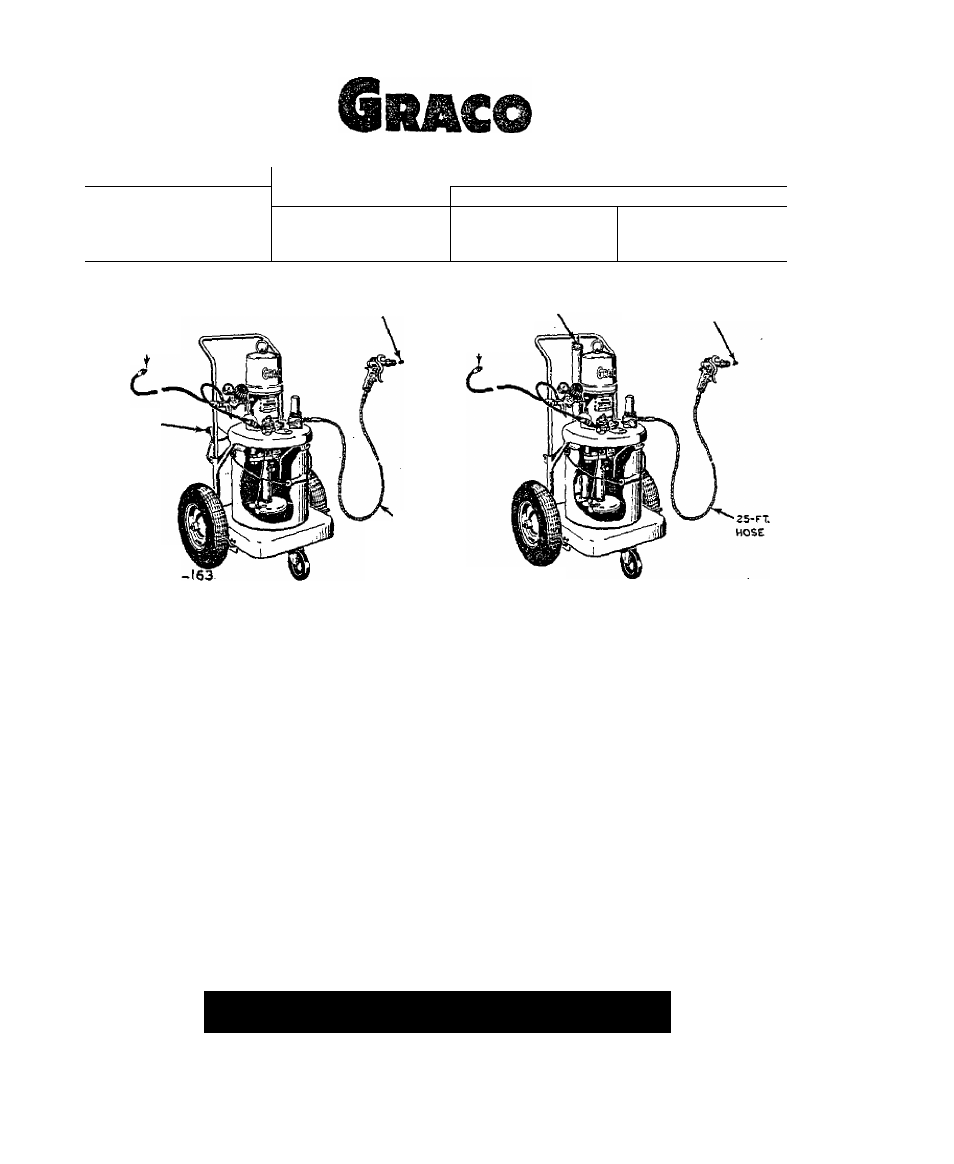

MODEL 226

ILLUSTRATED

I5“FT.

HOSE

MODEL 226-165

ILLUSTRATED

DESCRIPTION

These Hydra-Spray Units apply light materi

als by utilizing HI&H HYDRAULIC PRESSURE THROUGH

A SMALL FLUID ORIFICE. The combination of high

fluid pressure and small orifice creates fine

material breakup without atomizing air. This

airless spraying system without heat was origi

nally pioneered and developed by Graco engineers

to improve the consistency and lower the costs

of coating applications. The portable, truck-

mounted Hydra-Spray units wheel directly to the

work, wherever the job site...in-plant or out

side, on rough terrain or in a remote area.

Works direct from original 1 to 10 gallon con

tainers. Provides fast color changing for short

run work, quick mobility for constant one-color

application.

Units utilize air press\ire to (l) operate

the pump which powers the transfer of material

to the spray tip, (2) drive the agitator that

thoroughly mixes and keeps material solids in

sprayable suspension and (3) power the pneu

matic elevator, of Models 226-165 and 226-167,

for fast, easy material container changing. No

air used to atomize the material...no pressure

on container...no possible aeration of material.

Special, air-powered, reciprocating type pump

provides continuous-duty action, ’.dth equal pres

sure and volume delivery on both strokes. Pump

develops material pressure

28

times greeter than

the inbound air pressure. (For example: at 60 PSl

inbound air, the pump develops 1680 PSI material

pressure.)

Units are designed for high volumeprod

uction-type spraying of protective coating paints

and similar light materials, providing a heavy,

one coat application with almost complete elimi

nation of overspray. All units are equipped with

a material outlet manifold having a valve > for re

circulating material or dumping sludge. -.Also

manifold has an exrtra material outlet for addition

of a second spray gun. Models 226-165 and 226-167

include a filter kit, shipped loose, which can be

easily installed in manifold to filter the materi

al. Also Model 226-167 includes a surge tank,

shipped loose, that can be easily assembled to

manifold to eliminate material surge. NOTE:

A

tungsten carbide spray tip of customers choice is

included in all units. The proper spray tip to be

used for a specific material should be detennined

by a test conducted by your local Graco Industrial

Distributor or by his recommendation from previous

experience with the same or similar material.

7

RETAlNlFOlii-UtU^REFERENtE

• MINNEAPOLIS T3, MINN.

facterji

anuKha;

NEW YORK {Loa| Iilind Citri, PHILADELPHIA. DETROIT.

CHICAGO. ATLANTA, SAN FRANCISCO, HOUSTON

"