Graco HIGH EFFICIENCY LOW PRESSURE AA2000 User Manual

Air-assisted airiess spray gun, Instructions-parts list, High efficiency low pressure"” system

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

INSTRUCTIONS-PARTS LIST

■mmucnoNt

This manual contains important

warnings and information.

READ AND RETAIN FOR REFERENCE

<3

ORACO

307-947

Rev. E

Supersedes D

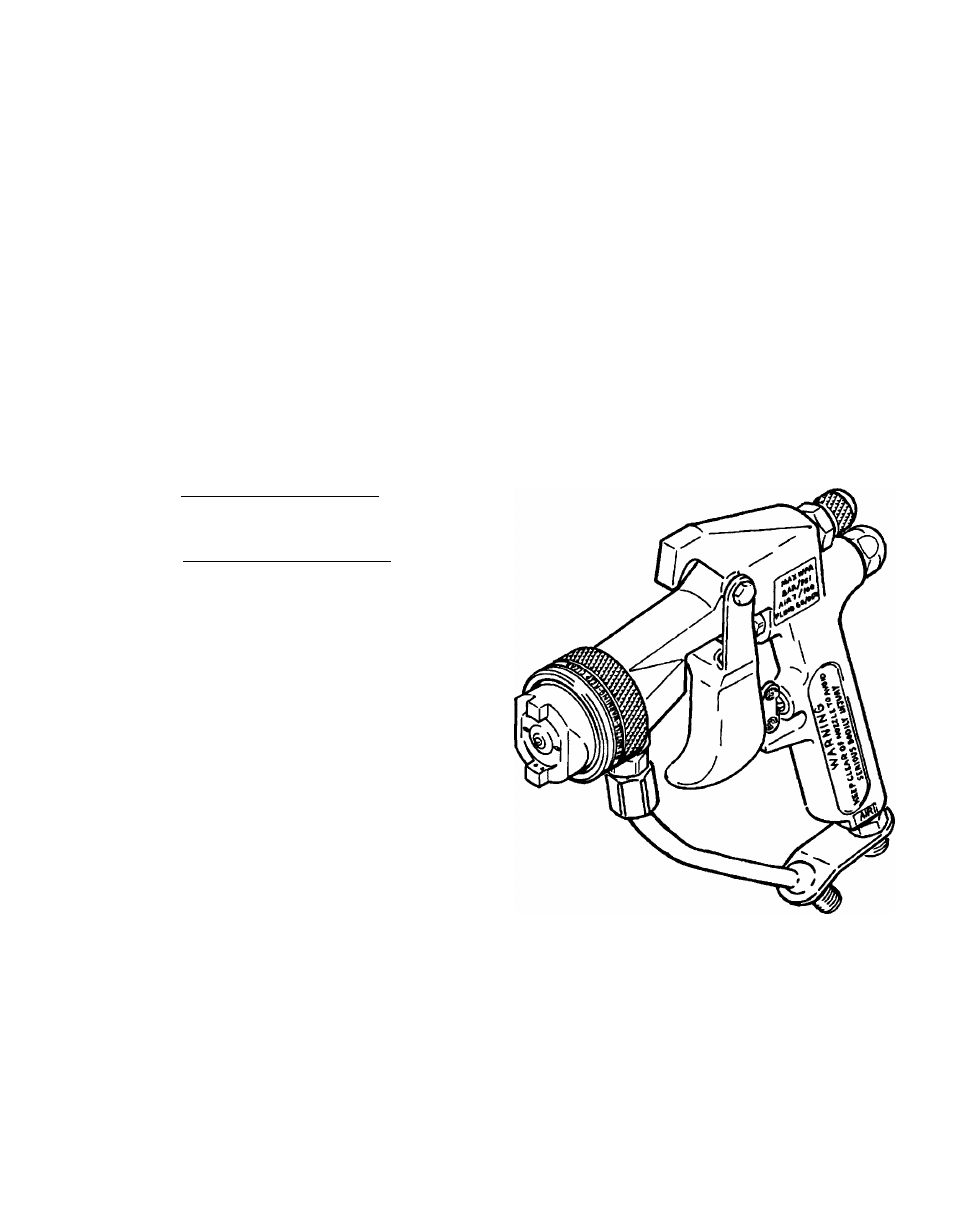

Model AA2000

High Efficiency Low Pressure"” System

Air-Assisted Airiess Spray Gun

Part Number 222-615, Series C

950 psi (66 bar) Maximum Working Fluid Pressure

100 psi (7 bar) Maximum Working Air Pressure*

10 psi (0.7 bar) Maximum Operating Air Pressure**

*

The

Maximum Working Air Pressure

indicates the maxi

mum air pressure the gun was designed to operate safely

under.

** The

Maximum Operating Air Pressure

indicates the maxi

mum air pressure the air cap supplied with this gun was

designed to operate at or below to comply with

California

Wood Rule 1136.

To guarantee compliance to rule 1136,

the gun must be used with Air Regulator Part No. 110-776.

This regulator limits the operating pressure to 10 psi (0.7

bar), using an air supply pressure of 100 psi (7 bar).

U.S. Patent Nos. 3,843,052; 4,386,739

United Kingdom Patent No. 2 111 406 B

Patented 1984 Canada

Brevete 1984

French Patent No. 82-21202

Foreign Patents Pending

GRACO INC.

P.O. BOX 1441 MINNEAPOLIS, MN

©COPYRIGHT 1988, GRACO INC.

55440-1441

Document Outline

- <3

- Part Number 222-615, Series C

- Ventilate the Spray Booth WARNING

- Required Accessories

- Connect the Air Line

- Connect the Fluid Line

- Grounding

- WARNING

- WARNING

- How the Air-Assisted Airless Spray Gun Operates

- WARNING

- Select a Spray Tip

- Install a Spray Tip

- WARNING

- Adjust the Spray Pattern & Apply the Fluid

- WARNING

- Adjust the Spray Pattern & Apply the Fluid (Continued)

- RIGHT

- Flush the Gun Daily

- WARNING

- Clean the Spray Gun & System Daily

- CAUTION

- CAUTION

- WARNING

- General Troubleshooting

- Spray Pattern Troubleshooting

- Air Valve Service

- CAUTION

- Fluid Packing Replacement