Stall pressure calibration – Graco ULTRA AIRLESS 230-963 User Manual

Page 25

STALL PRESSURE CALIBRATION

I

I

USE EXTREME CAUTION WHEN PERFORMING THIS CALIBRATION PROCEDURE to reduce the risk of a

fluid injection injury or other serious bodily injury which can result from splashing, component rupture, electric

shock, fire, explosion, or moving parts.

This procedure sets the sprayer to 192 bar (2750 psi)

MAXIMUM WORKING PRESSURE. This procedure

must be performed whenever a

new

or

used circuit

board, or pressure control assembly is removed and

reinstalled or replaced, to be sure the sprayer is pro-

perly calibrated.

pressurize and result

in

component rupture, fire or

Improper calibration can cause the sprayer to

explosion.

It

may also prevent the sprayer from ob-

taining the maximum working pressure which would

result in poor sprayer performance.

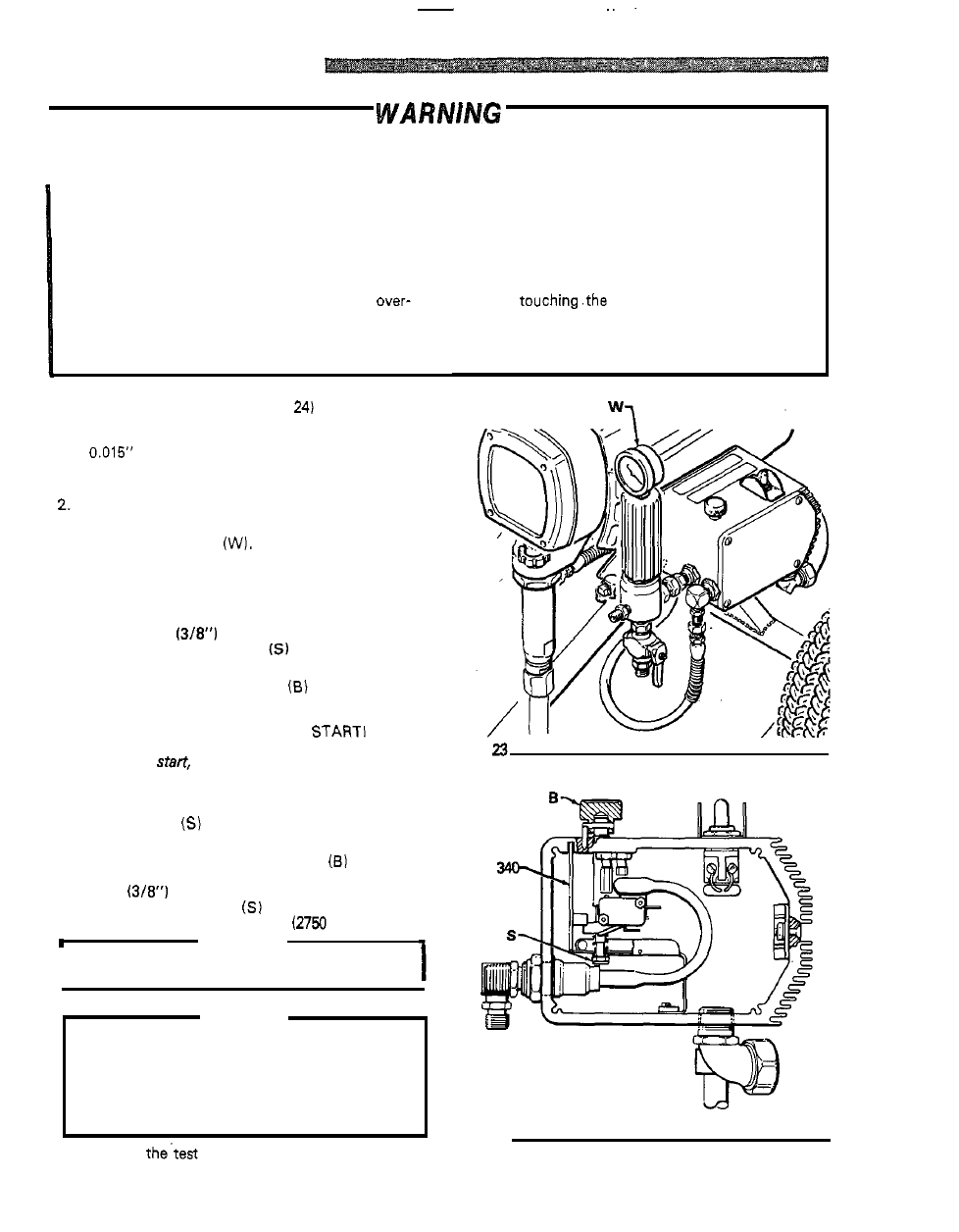

Calibration Setup

(See Fig

and

1. Follow the Pressure Relief Procedure Warning

a

spray tip in the gun. Connect the gun to a

on page 17. Remove the spray hose and gun. Install

outlet.

new test hose and connect the hose to the sprayer

Remove the pressure control screws and cover.

3. Remove the plug from the top of the

fluid filter, and

4. Place the pump suction tube

in

a

5 gallon pail of

install the test gauge

clean water.

5.

Be sure the gun safety latch is engaged.

6. Use a 9 mm

ignition wrench to turn the

pressure adjustment nut

counterclockwise

about

two

full turns. See Fig 24.

7. With the pressure control knob

at

the

minimum

setting, turn the sprayer switch ON.

THE SPRAYER SHOULD NOT

If

it

does

shut the. sprayer switch OFF,

disengage the gun safety latch, trigger

the

gun

into

a grounded waste container until pressure is reliev-

ed. Engage the gun safety latch. Turn the pressure

adjustment nut

a

little further counterclockwise.

Turn the sprayer on to be sure

it does nor

start.

8.

Slowly turn the pressure control knob

clockwise

to the maximum setting and hold

it

there. Use a

9

mm

ignition wrench to slowly turn the

pressure adjustment

nut

clockwise

until

the

test

gauge reads EXACTLY 192 bar

psi).

WARNING

I

Follow the Pressure Relief Procedure Warning

on page

CAUTION

To prevent pump corrosion,

flush the water out of

the pump, hose and gun with mineral spirits. Be

sure to close the drain valve, first. Use the lowest

pressure necessary to flush. Follow the Pressure

the mineral spirits

in

the pump to protect

it

until

Relief Procedure Warning

on page

Leave

you are ready to spray again.

9. Remove

gauge assembly and reinstall the

plug. Flush out water

with mineral spirits.

24

307-671

NEVER attempt to increase the fluid outlet pressure

by performing this calibration in any other way.

NEVER EXCEED 192 bar (2750 psi) MAXIMUM

WORKING PRESSURE. Normal operation of the

sprayer at higher pressures could result in compo-

nent rupture, fire or explosion.

AVOID

wires

in

the pressure control

assembly with your fingers or tools when the control

box cover is removed to reduce the risk of electric

shock.

Fig

Fig

24