Graco TEXSPRAY 1030 User Manual

Page 8

8

309662

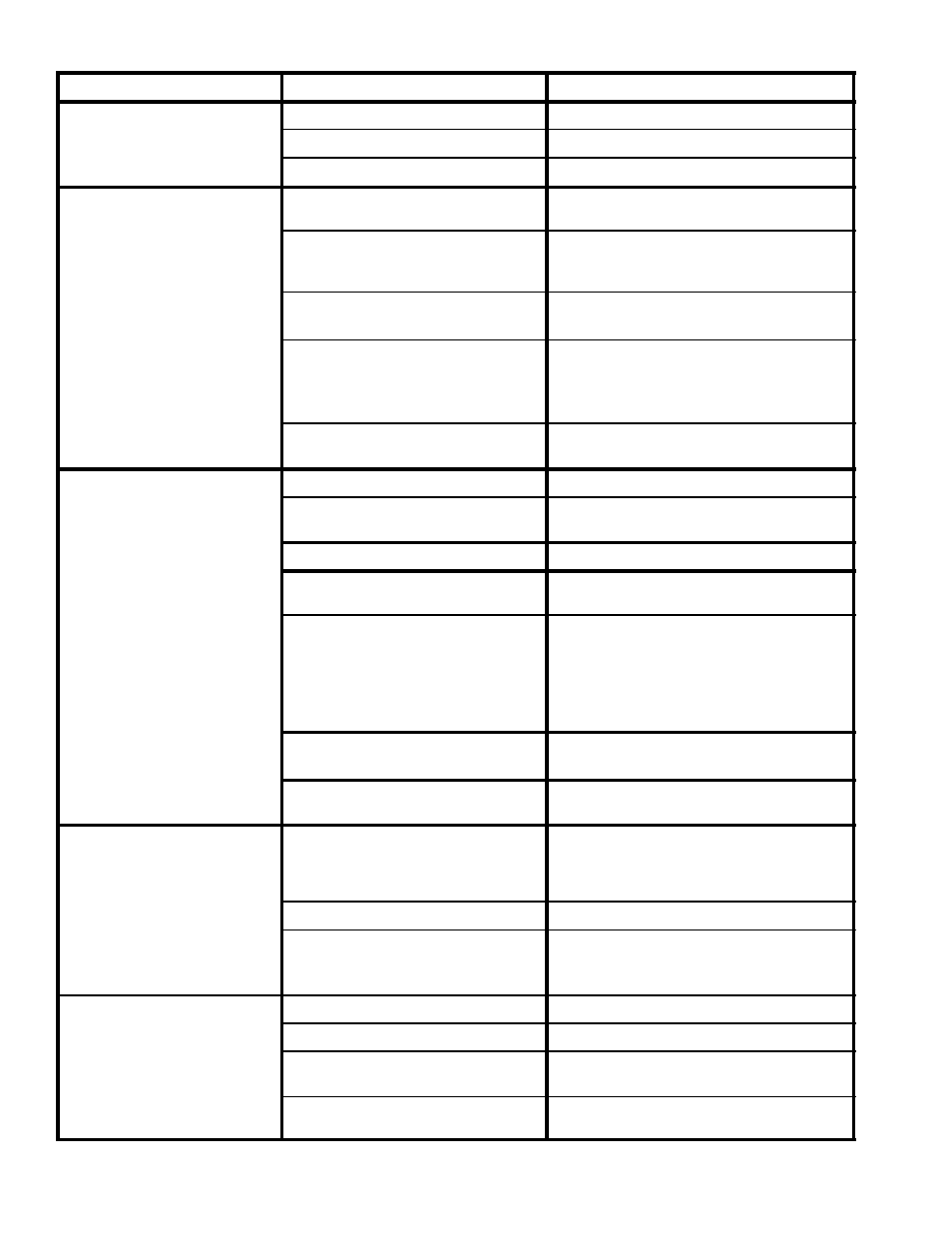

Troubleshooting (Continued)

PROBLEM

CAUSE

SOLUTION

Engine operates, but

displacement pump does not

Connecting rod worn or damaged

Replace connecting rod. See page 14.

displacement pump does not

(Continued)

Drive housing worn or damaged

Replace drive housing. See page 15.

(Continued)

Pinion assembly worn or damaged

Service pinion assembly. See page 16.

Engine operates, displace-

ment pump operates, but no

material pressure at gun

Flow control is set to PRIME

Set flow control to LOW/MED/HIGH while

triggering gun.

material pressure at gun.

Fluid system over--pressurized

Spraying material is too thick or the mate-

rial hose is too long. Use a less course

material or a shorter hose.

Gun nozzle/disk is clogged

Check and clean nozzle/disk as needed.

Switch to a larger nozzle/disk.

Material flowing out drain line

Check for air leaks to dump valve.

Check dump valve for wear, replace as

needed.

Air flow sensor dirty or damaged.

Pump is packed out

Disassemble and clean pump (see page

8), hose(s) and gun.

Low fluid delivery

Siphon hose strainer is clogged.

Clean or remove strainer

Engine RPM too low

Increase engine speed. See Startup,

procedure in operator manual.

Flow control set too low

Increase flow control to MED or HIGH

Hose too long or material too

coarse

Change to a shorter hose or less coarse

material.

Material flowing out drain line

Check drain line for a constant flow of

material when sprayer is operating in

LOW/MED/HIGH mode.

Check for air leaks to prime valve.

Check dump valve for wear, replace as

needed.

Gun nozzle/disk is clogged

Check and clean nozzle/disk as needed.

Switch to a larger nozzle/disk.

Pump is packed out

Disassemble and clean pump (see page

8), hose(s) and gun.

Loss of air control or volume

at gun

Gun air passages clogged with

material

After releasing gun trigger, make sure

system is fully depressurized before trig-

gering gun again. This helps prevent

material backing into gun passages.

Air filter dirty

Clean or replace element

Air flow sensor dirty or damaged

Check air filter.

Clean air flow sensor (see page 4) or re-

place as needed.

Displacement pump output

low on upstroke

Piston ball (220) not seating

Clean piston area. See page 12.

low on upstroke

Piston packings worn or damaged

Replace packings. See page 12.

Siphon hose coupling gasket (1e)

worn or missing.

Replace or install gasket

Pump cylinder o-ring (205) worn or

missing

Replace o-ring