Pinion assembly/rotor/field/shaft/clutch, Collar – Graco TEXSPRAY 1030 User Manual

Page 17

309662

17

Pinion Assembly/Rotor/Field/Shaft/Clutch

Installation

1. Fig. 14. Lay two stacks of two dimes on smooth

bench surface.

2. Lay armature (89) on two stacks of dimes.

3. Press center of clutch down on bench surface.

Fig. 14

4a

8705A

0.12 ±.01 in. (3.0 ±.25 mm)

4. Install armature (89) on engine drive shaft.

5. Install four screws (2) and lockwashers (43) with

torque of 125 in-lb.

6. Fig. 12. Tap pinion shaft (58d) in with plastic

mallet.

7. Install retaining ring (58e) with beveled side facing

field.

8. Fig. 11. Place pinion assembly (58) on bench with

rotor side up.

9. Apply locktite to screws. Install four screws (2) and

lockwashers (43). Alternately torque screws to 125

in-lb until rotor is secure. Use threaded holes to

hold rotor.

10. Fig. 10. Install pinion assembly (58) with five

screws (99) and lockwashers (43).

11. Connect field cable to flow control.

Collar

Removal

1. Fig. 15. Loosen two screws (2) on collar (86),

2. Push screwdriver into slot in collar (86) and re-

move collar.

Installation

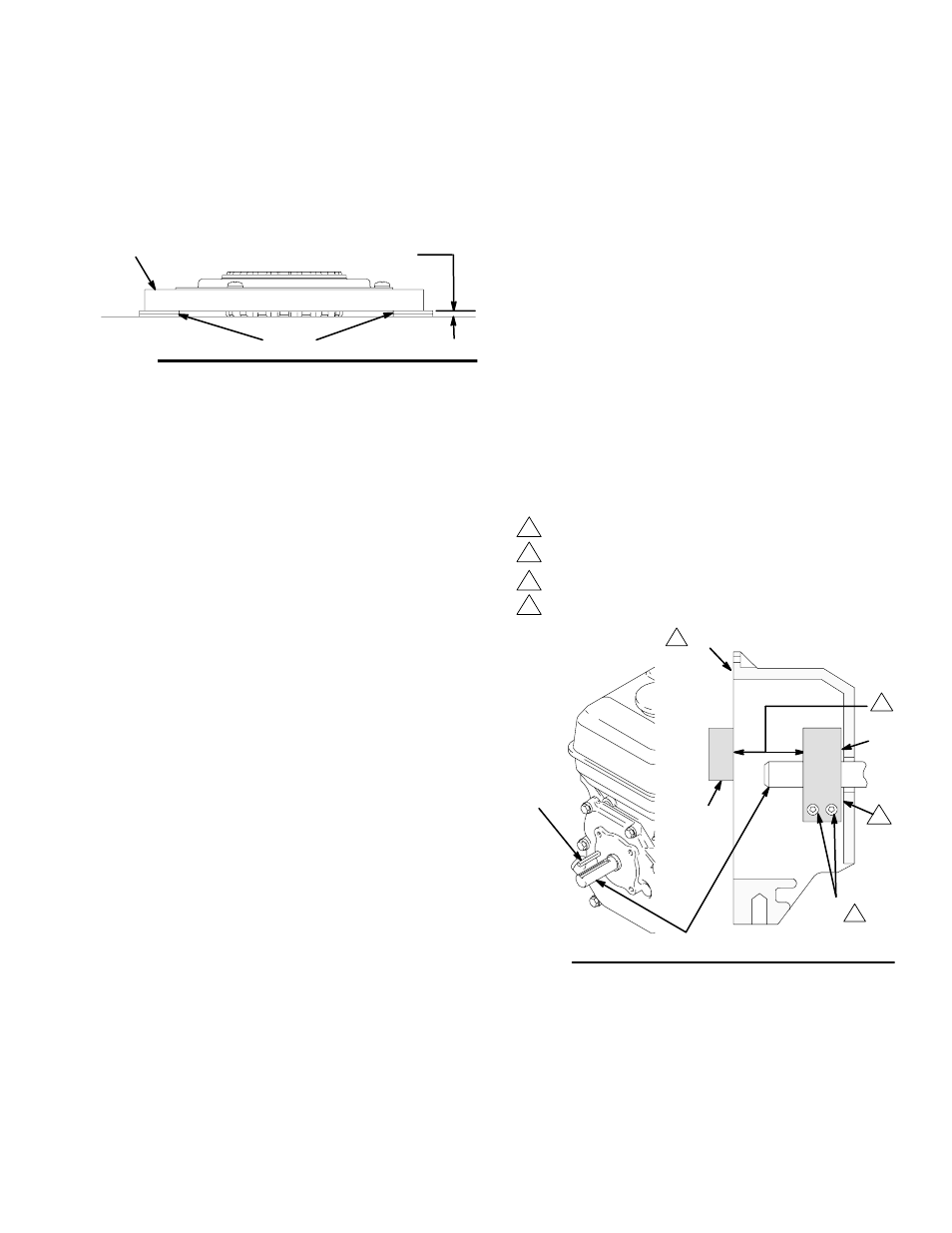

1. Fig.15. Install engine shaft key (90).

2. Tap collar (86) on engine shaft (A) with plastic

mallet.

3. Press collar (86) onto engine shaft (A). Maintain

dimension shown note 2 in Fig. 15. Chamfer must

face engine.

Check dimension: Place rigid, straight steel bar (B)

across face of clutch housing (88). Use accurate

measuring device to measure distance between

bar and face of collar. Adjust collar as necessary.

Torque two screws (16) to 125 ±10 in-lb (14 ±1.1

N¡m).

Fig. 15

2

88

B

03483

1

3

2

Face of clutch housing

1.812 ±.010 in. (46.02 ±.25 mm)

Torque to 125 ±.10 in-lb (14 ±1.1 N¡m)

1

2

3

90

86

A

4 Chamfer this side

4