Troubleshooting, Warning – Graco TEXSPRAY 1030 User Manual

Page 7

309662

7

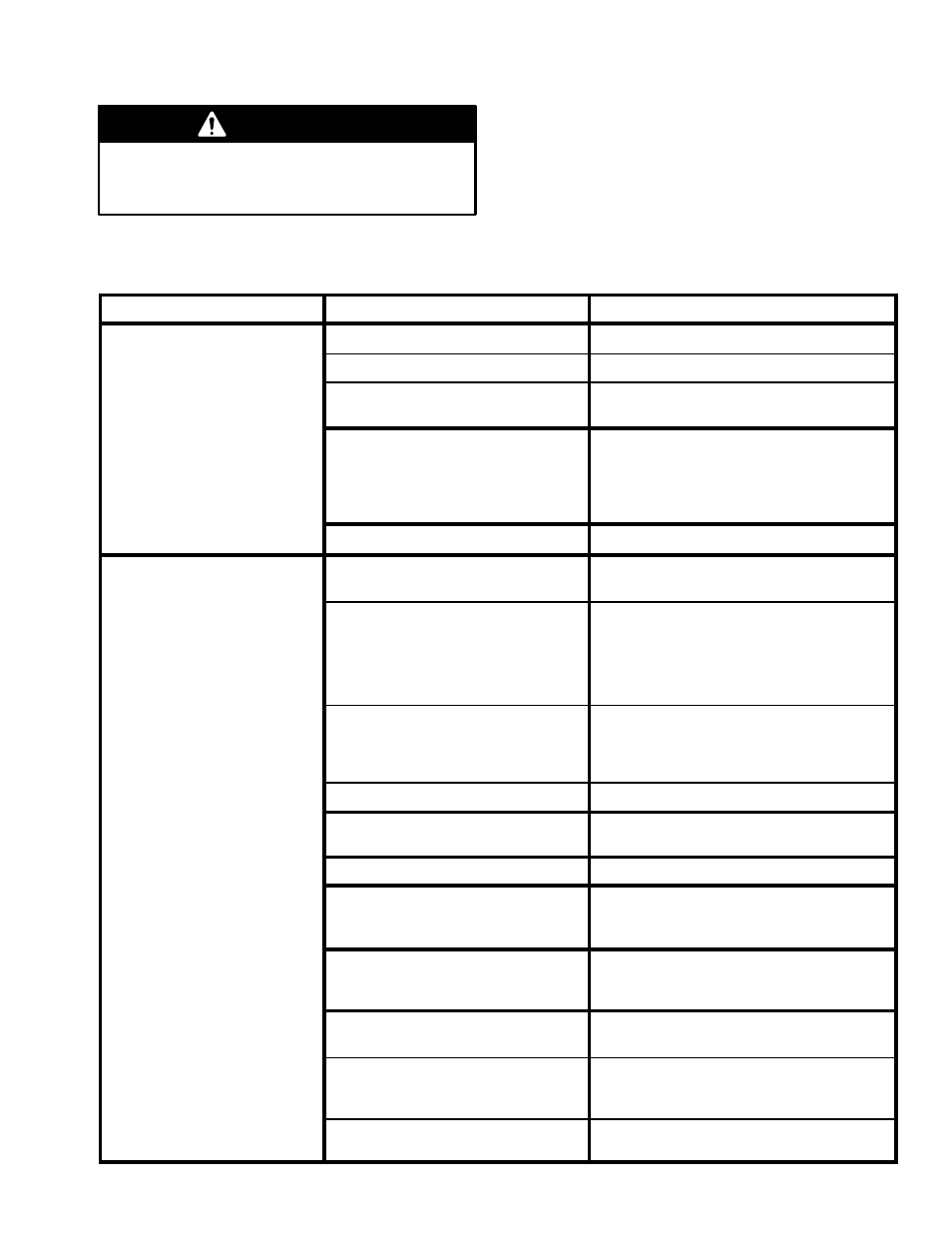

Troubleshooting

To reduce risk of injury due to sprayer starting

unexpectedly, shut off engine before performing

checks or service.

WARNING

Check everything in chart before disassembling sprayer.

PROBLEM

CAUSE

SOLUTION

Engine does not start

Engine switch not ON

Turn engine switch ON

Out of gas

Fill gas tank

Spark plug cable disconnected or

spark plug damaged

Connect spark plug cable or replace

spark plug

Oil seepage into combustion

chamber

Remove spark plug. Pull starter rope 3 or

4 times. Clean and install spark plug. Try

to start. Keep sprayer upright and do not

overfill engine crankcase to avoid oil

seepage.

Oil level low

Add oil to engine crankcase

Engine operates, but

displacement pump does not

Flow control set to OFF

Set flow control to PRIME mode or LOW/

MED/HIGH while triggering gun

Air compressor not on or insufficient

air flow from compressor

Start air compressor

Increase SCFM or compressor size.

Check air passages and tips for obstruc-

tions.

Check air filter element for clogs.

Air pressure set to low

Check display for air pressure. System

requires a minimum of 40 psi (0.28 MPa,

2.8 bar) to operate. Increase pressure by

adjusting air control knob.

Sprayer engine RPM too low

Increase engine speed

Clutch connector into back of circuit

board is loose.

Check and ensure a tight connection.

Air filter dirty

Clean or replace filter element.

Air flow sensor dirty or damaged

Check air filter.

Clean air flow sensor (see page 4) or re-

place as needed.

Air transducer failed

Check display for correct air pressure

reading. Replace circuit board as need-

ed.

Fluid transducer failed

Check connection at circuit board.

Replace fluid transducer.

Clutch not engaging

Worn or damaged clutch. See page 18.

Fluid transducer failure. Air transducer

failure.

Displacement pump rod seized by

dry coating

Service pump. See page 10.