Component description, Maintenance, Caution – Graco TEXSPRAY 1030 User Manual

Page 6

6

309662

Component Description

Compressor Requirements

NOTE: This sprayer requires an external air compres-

sor.

CAUTION

Install an air filter on external air compressor to

reduce contamination to spray system.

Air compressor range: 10 scfm to 35 scfm, 30 to 140

psi (0.2--0.97 MPa, 2 to 9.7 bar)

Material

Air Requirements*

Minimum

Compressor

Size*

Elastomerics

(textured)

30 scfm at 90 psi

(0.84 m

3

/min at

0.63 MPa, 6.3 bar)

15 HP

Simulated

Accoustical

20 scfm at 60 psi

(0.56 m

3

/min at

0.42 MPa, 4.2 bar)

5.5 HP

Splatter Coat

and

Knockdown

15 scfm at 40 psi

(0.42 m

3

/min at

0.28 MPa, 2.8 bar)

8 HP

Orange Peel

20 scfm at 60 psi

(0.56 m

3

/min at

0.42 MPa, 4.2 bar)

8 HP

* Material, temperature and volume affect cfm needed

to properly atomize material.

Maintenance

CAUTION

D

For detailed engine maintenance and specifica-

tions, refer to separate HONDA engine manual.

D

Close black fuel shutoff lever whenever you are

transporting sprayer to prevent fuel from flooding

engine.

D

Keep sprayer upright and level when operating it

and when transporting it. This prevents crankcase

oil from leaking into combustion chamber, which

makes startup very difficult.

Daily: Check engine oil level and fill as needed.

Daily: Check and fill gas tank.

Daily: Check sprayer air filter, clean and replace

element as needed.

After first 20 hours of operation and each 100

hours thereafter: Change oil.

Weekly: Remove engine air filter cover and clean

element. In very dusty environments, check filter daily.

Replace element as needed. Replacement elements

can be purchased from your local HONDA dealer.

Spark plug: Use only a (NGK) BP6ES or BPR6ES

plug. Gap plug to 0.025 to 0.030 in. (0.7 to 0.8 mm).

Always use a spark plug wrench.

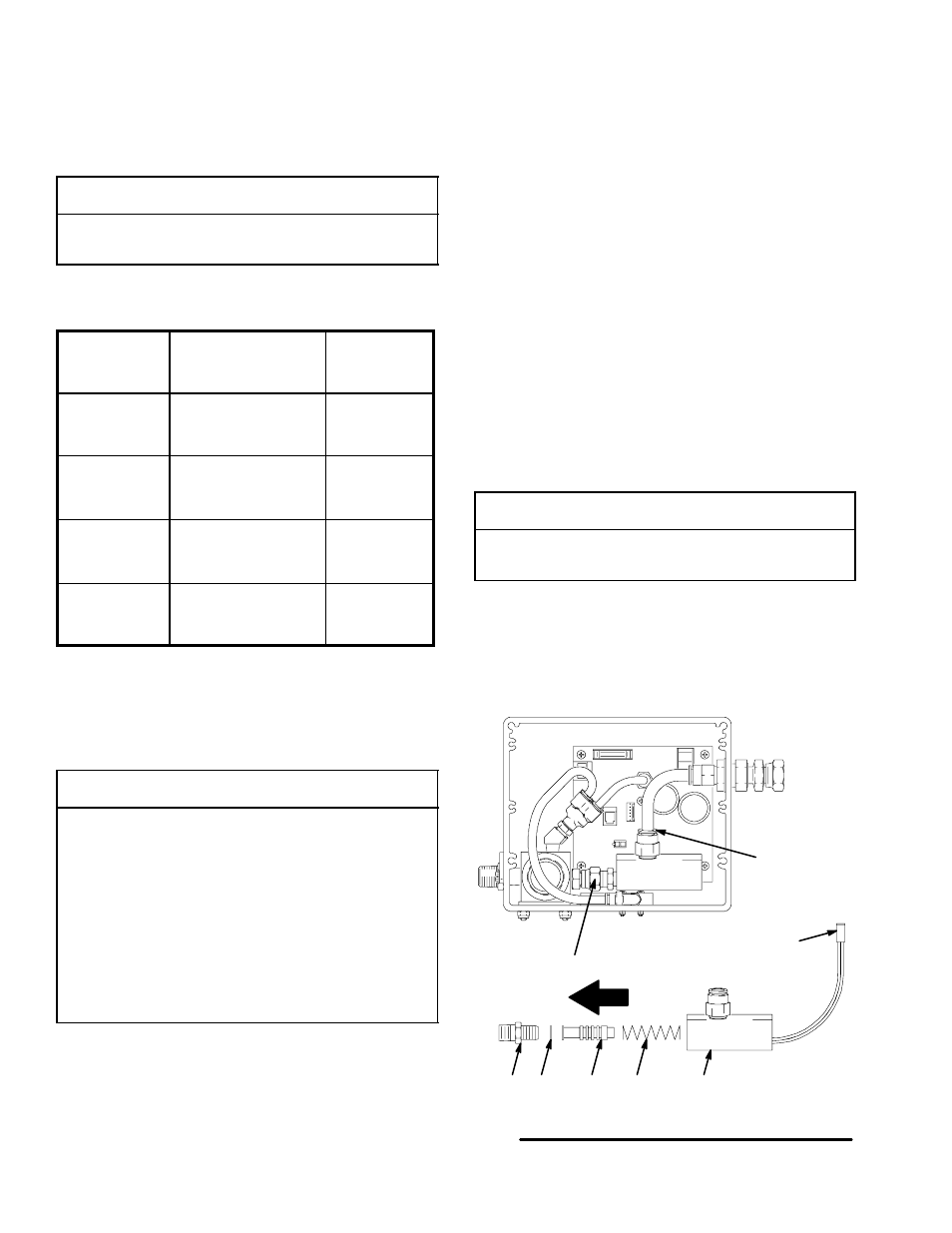

6 months: Clean Air Flow Sensor as follows:

1. Fig. 3. Loosen adapter (A). Pull down quick re-

lease (C) and swing out flow sensor regulator.

Disconnect connector (B).

2. Remove inlet fitting (D), retainer ring (E), piston (F)

and spring (G) from flow sensor regulator (H).

CAUTION

Do not scratch or nick piston (F) or inside of flow

sensor regulator (H).

3. Clean all parts (D, E, F, G). Clean inside of (H)

with a pipe cleaner.

4. Assemble all parts and install flow sensor regula-

tor.

Flow

Sensor Regulator

A

C

ti4366a

Flow

Sensor Regulator

B

D E

F

G

H

Fig. 3