Displacement pump repair, Warning – Graco TEXSPRAY 1030 User Manual

Page 10

10 309662

Displacement Pump Repair

Removal

To reduce risk of injury due to sprayer starting

unexpectedly, shut off engine before performing

checks or service.

WARNING

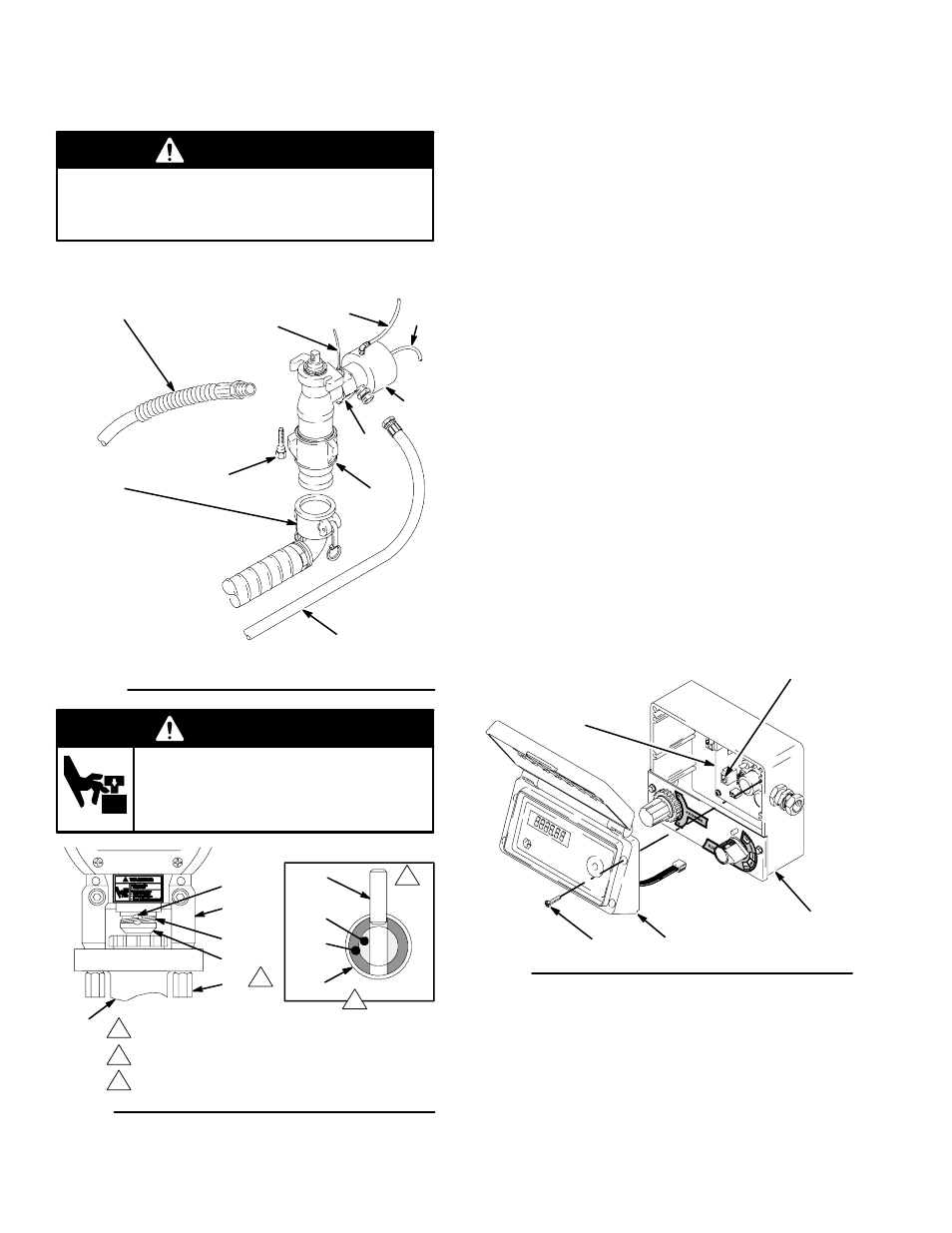

1. Fig. 4. Flush sprayer. Remove suction hose elbow

(150a), pump outlet hose (A) and drain hose (64).

TI3021B

Fig. 4

27

63

22

3

150a

A

64

85

159

158

MOVING PARTS HAZARD

To reduce risk of amputating fingers,

keep fingers away from connecting rod

and pin while jogging engine.

WARNING

0407

Torque to 20 ft--lb (27 N.m)

Fig. 5

38

23

37

128

27

38

201

128

61

1

1

2

3

2

Back of pump

Cutaway view shows how pin (38) goes

through connecting rod

3

3

2. Fig. 5. Start engine. Jog flow control between

PRIME and OFF until connecting rod stops near

bottom of stroke. Shut off engine.

3. Loosen two quick disconnect screws (27).

4. Pry retaining spring (37) up on connecting

rod (128). Push pin (38) out with a screwdriver.

5. Fig. 6. Remove cover (C) to control housing (54)

by removing four screws (12). Detach pressure

transducer cord (63, Fig. 4) from control board (9)

at port (D). Remove pressure transducer cord from

control box.

6. Fig. 4. Remove air hoses (158) and (159) from

prime valve manifold (85). Note correct air hose

connection to ports on air cylinder (22). Use 5/16

inch wrench to hold ring on hose fitting while

removing hose from fitting.

7. Support weight of pump (3) and remove two quick

disconnect screws (27).

8. Unscrew assembled dump valve manifold (85) and

air cylinder (22) from pump (3).

Fig. 6

ti3007b

12

D

9

C

54

Repair

See page 12 for pump repair instructions.