Electrical troubleshooting – Graco Inc. UNICARB Pro AA4500 User Manual

Page 24

24 308936

Electrical Troubleshooting

NOTE: Additional gun troubleshooting can be done on Gun Part No. 236031 using the Remote Spraying Voltage Read-

out (SVR

t). See Accessories to order the SVR.

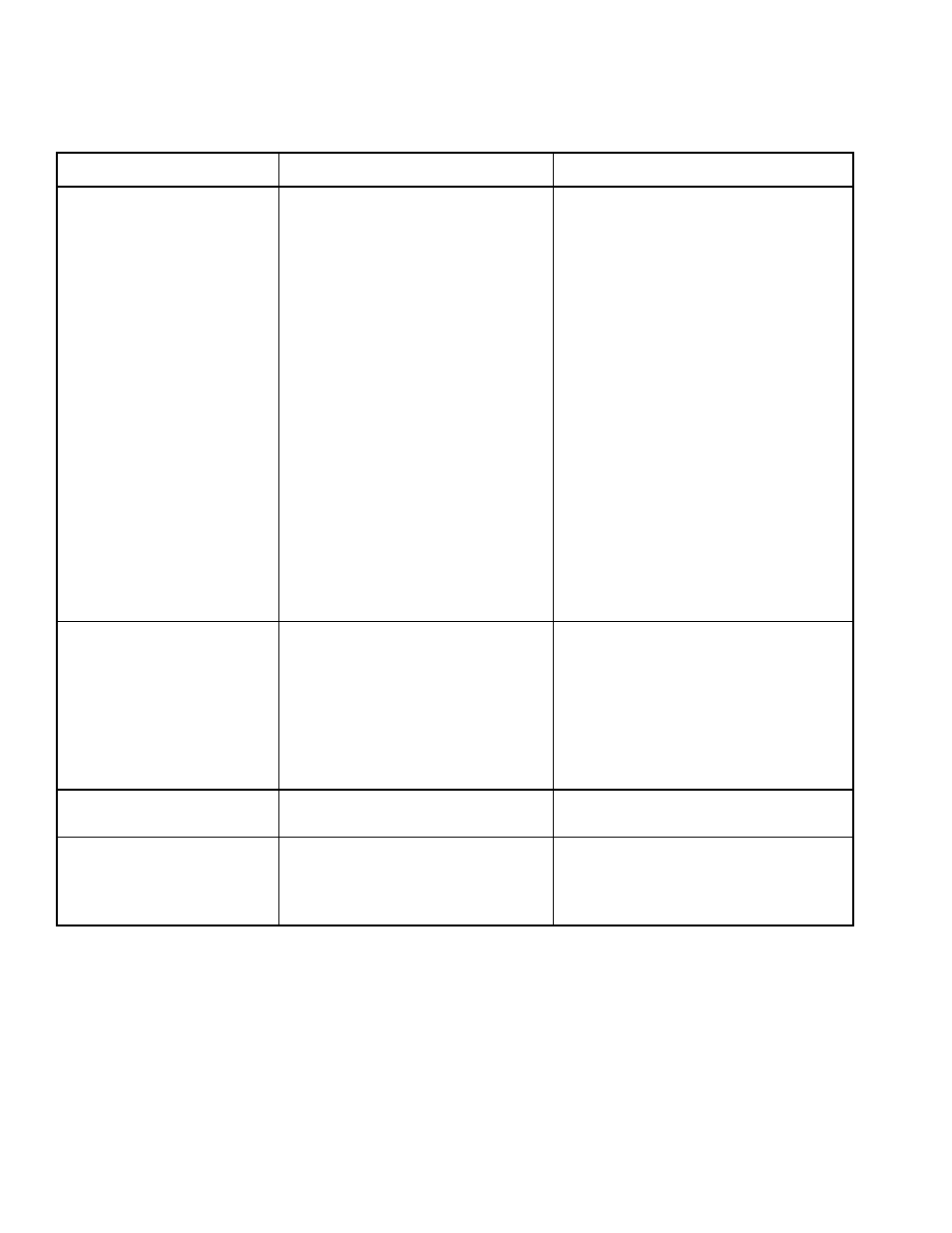

PROBLEM

CAUSE

SOLUTION

Reduced fluid efficiency

Improper distance between gun and

work-piece

Parts poorly grounded

High booth exhaust velocity

Fluid pressure too high

Improper fluid viscosity

Fluid resistivity too low

No or low voltage output

Turbine alternator not operating

Faulty gun resistance

Fluid leaks from needle packing and

causes short

Faulty turbine alternator

kV switch stuck on low

Adjust spraying distance to 8 to 12 inches

(203 to 305 mm)

Clean hangers; Check for proper ground on

conveyer or track

Reduce exhaust velocity within code limits

Reduce fluid pressure at fluid supply

Check supplier for proper fluid for electro-

static spray

Check fluid resistivity with paint meter and

probe

Check possible causes listed below

Check air supply to turbine inlet; See page 15

Check gun resistance; See page 25

Clean needle cavity; Replace fluid needle;

See page 34

Be sure plug is in place on back of turbine

alternator housing; Remove and test turbine

alternator; See page 36

Check switch actuation; replace if needed

Operator gets shock

Operator not properly grounded or is

near an ungrounded object

Gun not properly grounded

Be sure floor is properly grounded; Wear

shoes with conductive soles or wear personal

grounding straps; Be sure operator is not in

contact with or carrying any metallic items

which could build up electrical charge; If

worn, a glove must be conductive or modified

as shown on page 9

See Check the Electrical Grounding,

page 12

Operator gets shock when

touching workpiece

Workpiece not properly grounded.

Clean workpiece hangers; Check for proper

ground on conveyor or track

No or low voltage output reading

on gun display module

Damaged fiber optic cable or

connection

Check cables and connections; replace if

damaged

See other causes under Problem –

Reduced fluid efficiency, above

NOTE: If using an ES Display Module, see its instruction manual, No. 308265, for further troubleshooting.