Nno ot tiic ce e – Grizzly G4000 User Manual

Page 24

G4000 9'' x 19'' Lathe

-23-

N

NO

OT

TIIC

CE

E

S

Slliip

p C

Cllu

uttc

ch

h::

To avoid overloading the drive, a

safety slip clutch is fitted in the idler pulley.

Overloading the drive at slower speeds (rattling

noise) means the depth of cut is too deep and

should be reduced.

E

Ex

xa

am

mp

plle

e o

off G

Ge

ea

arr S

Se

ett--U

Up

p tto

o C

Cu

utt 1

10

0 T

T..P

P..ll..::

1

1..

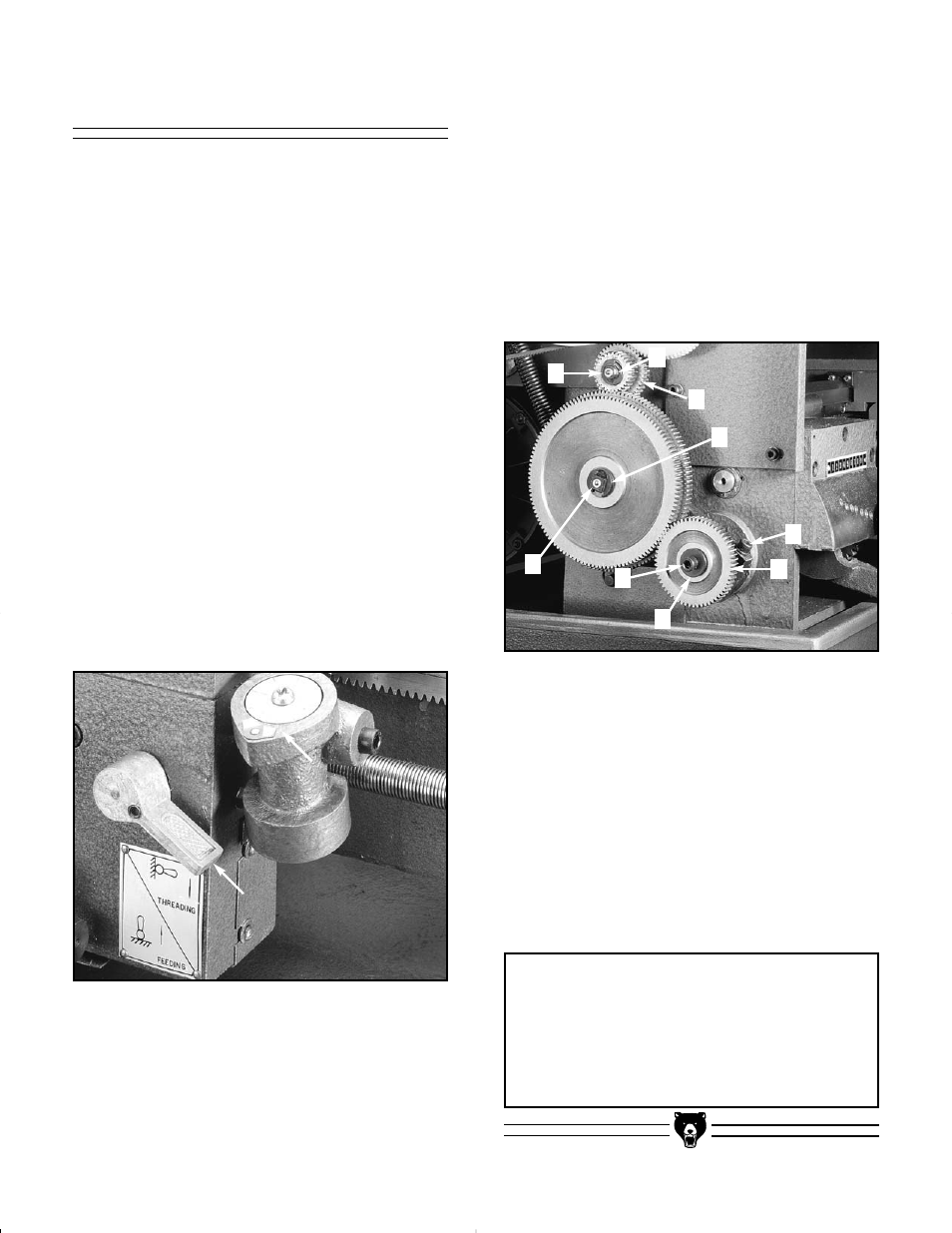

Loosen cap screw

((1

1))

.

F

Fiig

gu

urre

e 3

35

5..

2

2..

Loosen bolt

((2

2))

. Remove washers

((3

3))

and

gear

((6

6))..

3

3..

Loosen bolts

((7

7))

to allow movement in the

center gear position.

4

4..

Loosen nuts

((5

5))..

Remove washer

((4

4))

and

gear

((8

8))..

R

Re

ea

as

ss

se

em

mb

blle

e a

as

s ffo

ollllo

ow

ws

s::

1

1..

Install 30 tooth gear in position

((6

6))

with bush-

ings, washer, and bolt.

2

2..

Install 60 tooth gear in position

((8

8))..

3

3..

Center 127 tooth gear remains in place.

4

4..

Adjust gear to mesh with upper and lower

gear and tighten bolts

((7

7))..

T

Th

hrre

ea

ad

d C

Cu

uttttiin

ng

g

Several different threads can be cut using the

proper combination of gears and settings. When

cutting inch threads, the half nut and threading

dial are used to thread in a conventional manner.

F

Fiig

gu

urre

e 3

34

4..

The thread dial chart specifies at

which point a thread can be entered using the

threading dial.

M

Me

ettrriic

c T

Th

hrre

ea

ad

d C

Cu

uttttiin

ng

g

- The only difference in

metric thread cutting is,

tth

he

e h

ha

allff n

nu

utt m

mu

us

stt

rre

em

ma

aiin

n e

en

ng

ga

ag

ge

ed

d d

du

urriin

ng

g tth

he

e e

en

nttiirre

e tth

hrre

ea

ad

diin

ng

g

p

prro

oc

ce

es

ss

s..

The thread dial cannot be utilized.

Set the machine up for the desired thread pitch.

Start the machine and engage the half nut. When

the tool reaches the workpiece, it will cut the ini-

tial threading pass. When the tool reaches the

end of the cut, stop the machine by turning the

motor off and at the same time back the tool out

of the workpiece so that it clears the thread.

D

Do

o

n

no

ott

disengage the half nut lever. Reverse the

motor direction to allow the cutting tool to traverse

back to the starting point. Repeat these steps

until you have obtained the desired results.

F

Fiig

gu

urre

e 3

34

4..

Half nut and threading dial.

F

Fiig

gu

urre

e 3

35

5..

Gear train adjustment points.

5

5

4

4

8

8

4

4

7

7

2

2

3

3

6

6

1

1