Guardian Technologies 4758 User Manual

Page 19

SECTION 1.4

TESTING, CLEANING AND DRYING

PART 1

GENERAL INFORMATION

5. Insert a large paper clip into Pin Location No. 1 (Wire

77). Connect the red tester probe to the paper clip.

Connect the black tester probe to Stator Lead 33. Refer

to Steps 5a through 5c of “TESTING ALL STATOR

WINDINGS TO GROUND” on the previous page.

6. Repeat Step 5 at Pin Location 3 (Wire 66A) and Stator

Lead 33.

7. Repeat Step 5 at Pin Location 7 (Wire 6) and Stator

Lead 33.

For the following steps (8 through 10) an additional

large paper clip (or similar item) will be needed:

8. Insert a large paper clip into Pin Location 1 (Wire 77).

Connect the red tester probe to the paper clip. Insert the

additional large paper clip into Pin Location 3 (Wire

66A). Connect the black tester probe to this paper clip.

Refer to Steps 5a through 5c of “TESTING ALL

STATOR WINDINGS TO GROUND” on the previous

page.

9. Insert a large paper clip into Pin Location 1 (Wire 77).

Connect the red tester probe to the paper clip. Insert the

additional large paper clip into Pin Location 7 (Wire 6).

Connect the black tester probe to this paper clip. Refer

to Steps 5a through 5c of “TESTING ALL STATOR

WINDINGS TO GROUND” on the previous page.

10.Insert a large paper clip into Pin Location 3 (Wire 66A).

Connect the red tester probe to the paper clip. Insert the

additional large paper clip into Pin Location 7 (Wire 6).

Connect the black tester probe to this paper clip. Refer

to Steps 5a through 5c of “TESTING ALL STATOR

WINDINGS TO GROUND” on the previous page.

ROTOR INSULATION RESISTANCE TEST

Before attempting to test rotor insulation, the brush

holder must be completely removed. The rotor must

be completely isolated from other components before

starting the test. Attach all leads of all stator windings

to ground.

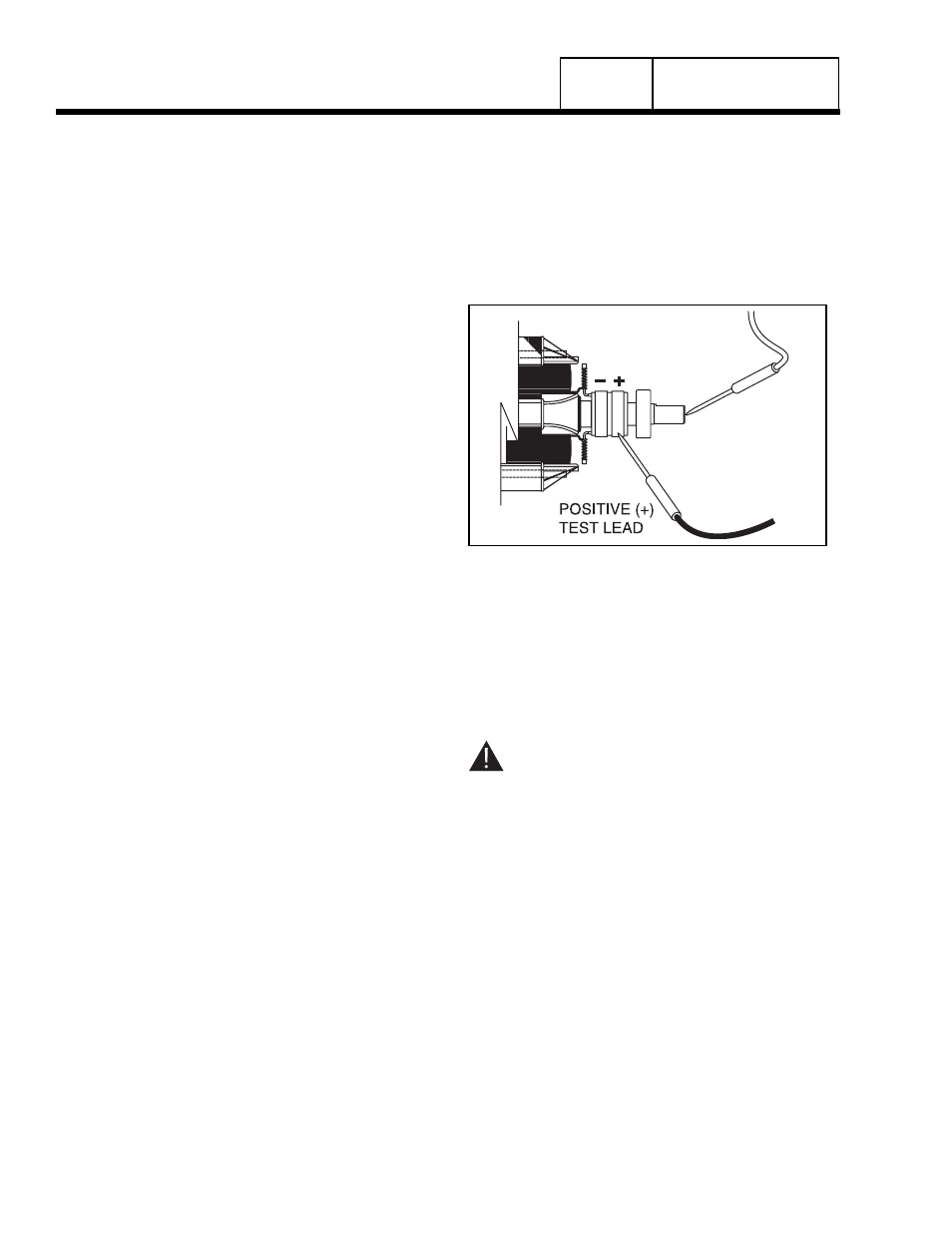

1. Connect the red tester lead to the positive (+) slip ring

(nearest the rotor bearing).

2. Connect the black tester probe to a clean frame ground,

such as a clean metal part of the rotor shaft.

3. Turn the tester switch OFF.

4. Plug the tester into a 120 volts AC wall socket and set

the voltage switch to "1500 volts".

5. Turn the tester switch "On" and make sure the pilot light

has turned on.

6. Observe the breakdown lamp, then turn the tester

switch OFF. DO NOT APPLY VOLTAGE LONGER

THAN ONE (1) SECOND.

If the breakdown lamp came on during the one (1)

second test, cleaning and drying of the rotor may be

necessary. After cleaning and drying, repeat the

insulation breakdown test. If breakdown lamp comes

on during the second test, replace the rotor assembly.

Figure 4. Testing Rotor Insulation

CLEANING THE GENERATOR

Caked or greasy dirt may be loosened with a soft

brush or a damp cloth. A vacuum system may be

used to clean up loosened dirt. Dust and dirt may also

be removed using dry, low-pressure air (25 psi

maximum).

CAUTION: Do not use sprayed water to clean

the generator. Some of the water will be

retained on generator windings and terminals,

and may cause very serious problems.

DRYING THE GENERATOR

To dry a generator, proceed as follows:

1. Open the generator main circuit breaker. NO

ELECTRICAL LOADS MUST BE APPLIED TO THE

GENERATOR WHILE DRYING.

2. Disconnect all Wires 4 from the voltage regulator.

3. Provide an external source to blow warm, dry air

through the generator interior (around the rotor and

stator windings. DO NOT EXCEED 185° F. (85° C.).

4. Start the generator and let it run for 2 or 3 hours.

5. Shut the generator down and repeat the stator and rotor

insulation resistance tests.

Page 1.4-6