Guardian Technologies 4758 User Manual

Page 129

SECTION 6.1

MAJOR DISASSEMBLY

PART 6

DISASSEMBLY

Figure 7. Removing the Rotor

16.Remove Engine: Using a 13mm socket, remove the

two engine mount nuts, and ground wires.

Remove the engine.

17. Reverse the previous steps to re-assemble.

Figure 8. Removing the Engine

FRONT ENGINE ACCESS

1. Follow Stator/Rotor/Engine removal procedures,

Steps 1-5.

2. Control Panel Removal: Using a 7mm socket remove

the eight bolts from male connectors C1 and C2.

Remove connectors engine divider panel.

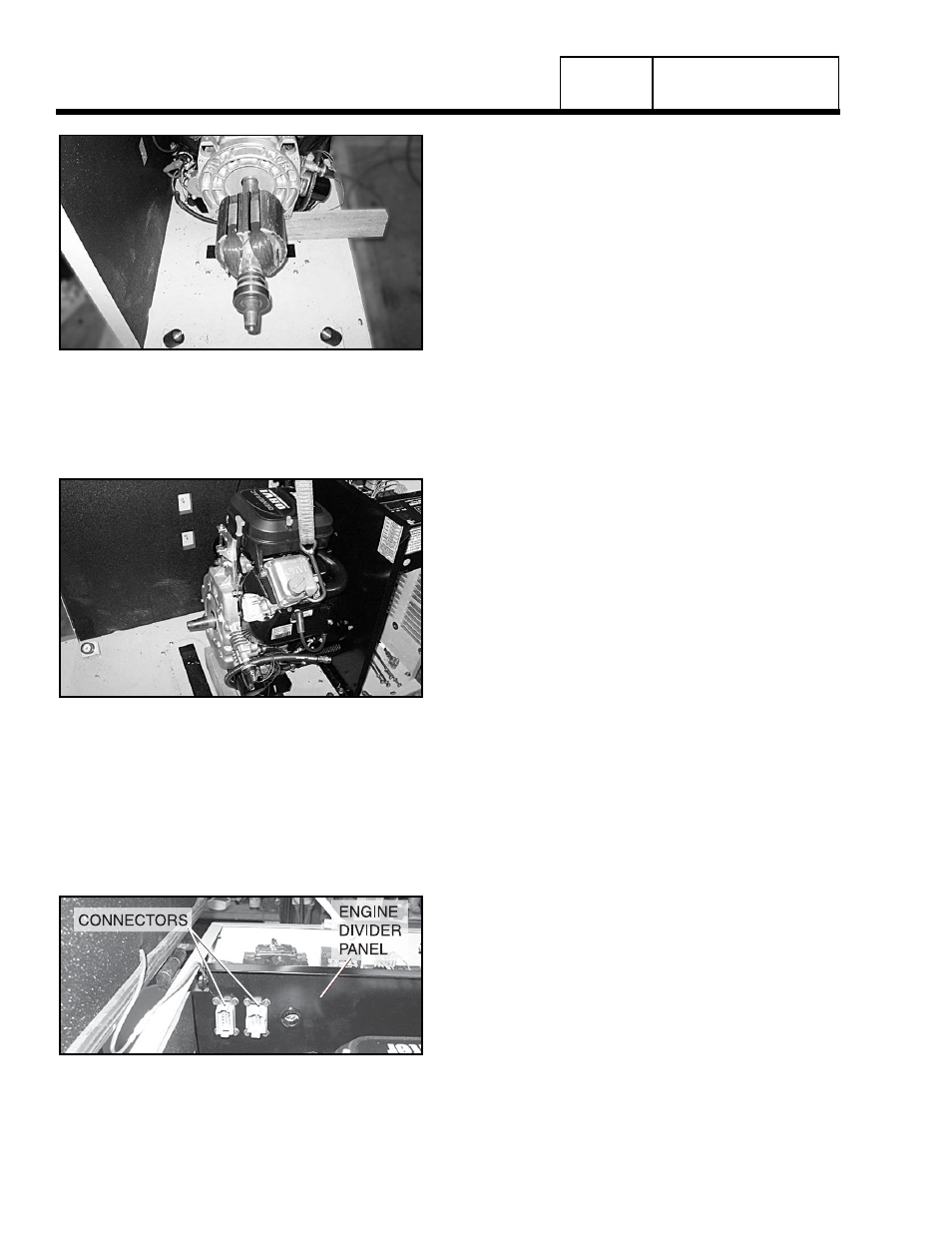

Figure 9. C1 and C2 Connectors Located on the

Engine Divider Panel

Using a 10mm socket, remove the six (6) nuts attaching

the control panel to the side/back enclosure and the

engine divider panel. Remove the two (2) nuts

connected to the back enclosure located on the top side

of control panel. Remove the two (2) nuts located

underneath the middle of the control panel, connecting

to the back/side enclosure and the engine divider panel.

Remove the two (2) nuts from the front top side of the

control panel, connecting to the back/side enclosure

and the engine divider panel. Remove the control panel.

3. Remove Engine Divider Panel: Using a 10mm socket,

remove the remove the two (2) nuts attached to the

back enclosure. Remove the two bolts attached to the

base enclosure. Remove the engine divider panel.

4. Remove Intake manifolds: Using a 6mm allen wrench,

remove the four (4) socket head cap screws from the

intake manifolds. Remove the intake manifolds.

Remove the air intake snorkel.

5. Remove Air Box: Using a 5/32 allen wrench, remove

the four (4) air box allen head shoulder bolts. While

removing the air box remove the four rubber washers

and disconnect the throttle linkage and anti-lash spring.

6. Unbolt Oil Cooler: Using a 10mm socket, remove the

four (4) oil cooler bolts.

7. Remove Blower Housing: Using an 8mm socket,

remove the nine (9) bolts around the blower housing.

Remove the blower housing.

8. Remove flywheel: Use a 36mm socket, a steering

wheel puller, two (2) M8x1.25 bolts and a 13 mm

socket. Remove the flywheel hex nut, remove the fan

plate and fan. Install the puller using the M8x1.25 bolts

and remove the flywheel.

TORQUE REQUIREMENTS (UNLESS OTHERWISE SPECIFIED)

FLYWHEEL NUT . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 FT-LBS

STATOR BOLTS . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 FT-LBS

ROTOR BOLT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 FT-LBS

ENGINE ADAPTER . . . . . . . . . . . . . . . . . . . . . . . . . 25 FT-LBS

EXHAUST MANIFOLD . . . . . . . . . . . . . . . . . . . . . . 18 FT-LBS

INTAKE MANIFOLD (TO CYLINDER HEAD) . . . . . 22 FT-LBS

M5-0.8 TAPTITE SCREW INTO ALUMINUM . . . 25-50 IN-LBS

M5-0.8 TAPTITE SCREW INTO PIERCED HOLE 25-50 IN-LBS

M6-1.0 TAPTITE SCREW INTO ALUMINUM . . . 50-96 IN-LBS

M6-1.0 TAPTITE SCREW INTO PIERCED HOLE 50-96 IN-LBS

M6-1.0 TAPTITE SCREW INTO WELDNUT . . . . 50-96 IN-LBS

M8-1.25 TAPTITE SCREW INTO ALUMINUM . . 12-18 FT-LBS

M6-1.0 NYLOK NUT ONTO STUD . . . . . . . . . . . 16-65 IN-LBS

NOTE: TORQUES ARE DYNAMIC VALUES WITH ±10%

TOLERANCE UNLESS OTHERWISE NOTED.

Page 6.1-3