V-belt tensioning, Leadscrews – Grizzly Vertical Milling Machines G0728 User Manual

Page 35

Model G0728–31 (Mfg. Since 11/11)

-33-

Leadscrews

Lubricant

frequency

Qty

nlgi #2 grease

Every

40 hours

of operation

thin

Coat

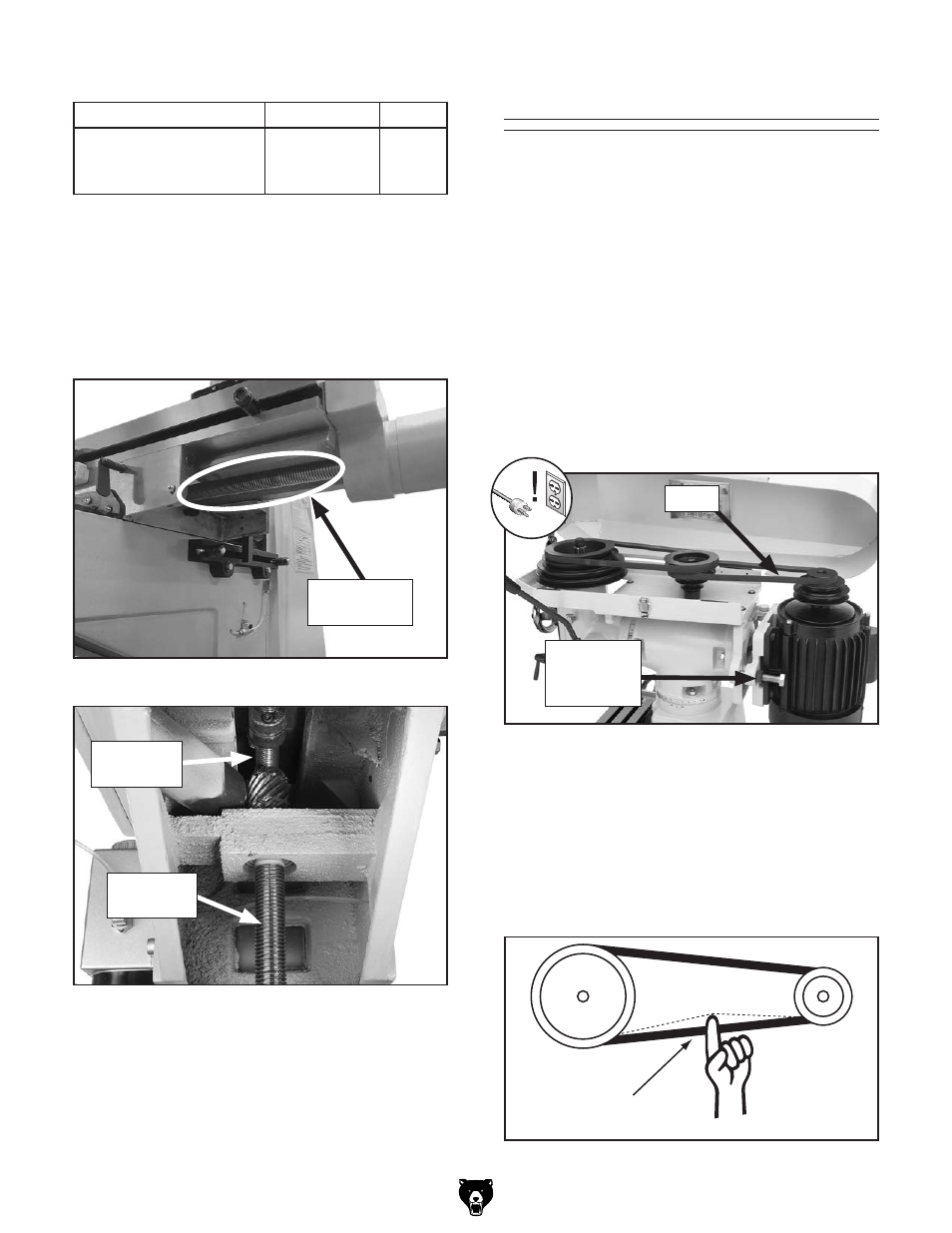

use a shop rag, stiff brush, and mineral spirits

to clean away debris and grime from the lon-

gitudinal, cross, and elevation leadscrews and

leadscrew nuts. apply a thin coat of lubricant to

the leadscrews, then move the table through the

full range of movement for each leadscrew to dis-

tribute the grease (see

figures 44–45).

figure 45. Cross and vertical leadscrews.

Cross

leadscrew

vertical

leadscrew

V-belt Tensioning

power is transferred from the motor to the spindle

with a v-belt. With normal use, this belt will gradu-

ally stretch over time. When it does, perform the

following procedures to re-tension it.

Tools Needed

Qty

Wrench 24mm ................................................... 2

To tension the V-belt:

1. DisConnECt thE Mill FroM poWEr!

2. lift the v-belt cover, then loosen the adjust-

ment bolt jam nut near the motor (see

figure 46).

3. the v-belts tighten uniformly because of the

idler pulley. rotate the adjustment bolt until

the v-belt has approximately

1

⁄

8

" of deflection

when moderate pressure is applied midway

between the pulleys (see

figure 47), then

re-tighten the jam nut and close the v-belt

cover.

Approximately 1/8"

Deflection

figure 47. Checking for belt deflection.

figure 46. v-belt tension adjustment bolt.

v-Belt

adjustment

Bolt & Jam

nut

figure 44. longitudinal leadscrew.

longitudinal

leadscrew