Barranca Diamond CAB COMBO WORKSHOP User Manual

Page 28

28

deflection when the belt is pushed down (fig 63). If the belt tension should become loose, poor sawing

performance or slipping will result. If the belt is too tight (i.e. no deflection) the belt, electric motor, pul-

leys and blade arbor bearings may wear out prematurely or the motor may overheat and shut off. Belt

tension can be adjusted by loosening the two mounting bolts attached to the base of the motor mount

and sliding the motor cradle base forward or backward to increase or decrease belt tension. Be sure

to adequately retighten the motor mount nuts and replace and attach the belt guard to the table as

well.

BLADE ARBOR ASSEMBLY AND PULLEYS

The Cab Combo Workshop is equipped with a 5/8" OD arbor shaft with 2" OD x 5/8" bore aluminum

flanges and spacers, two rubber sealed ball bearings, felt gasket and 2" OD x 5/8" bore die cast zinc

coated pulley. Should the bearings wear out on the arbor shaft, poor sawing, grinding and polishing

performance and overheating may result causing permanent damage to the shaft, bearings, belt and

motor. This main stainless steel shaft arbor assembly can be purchased from Barranca Diamond as

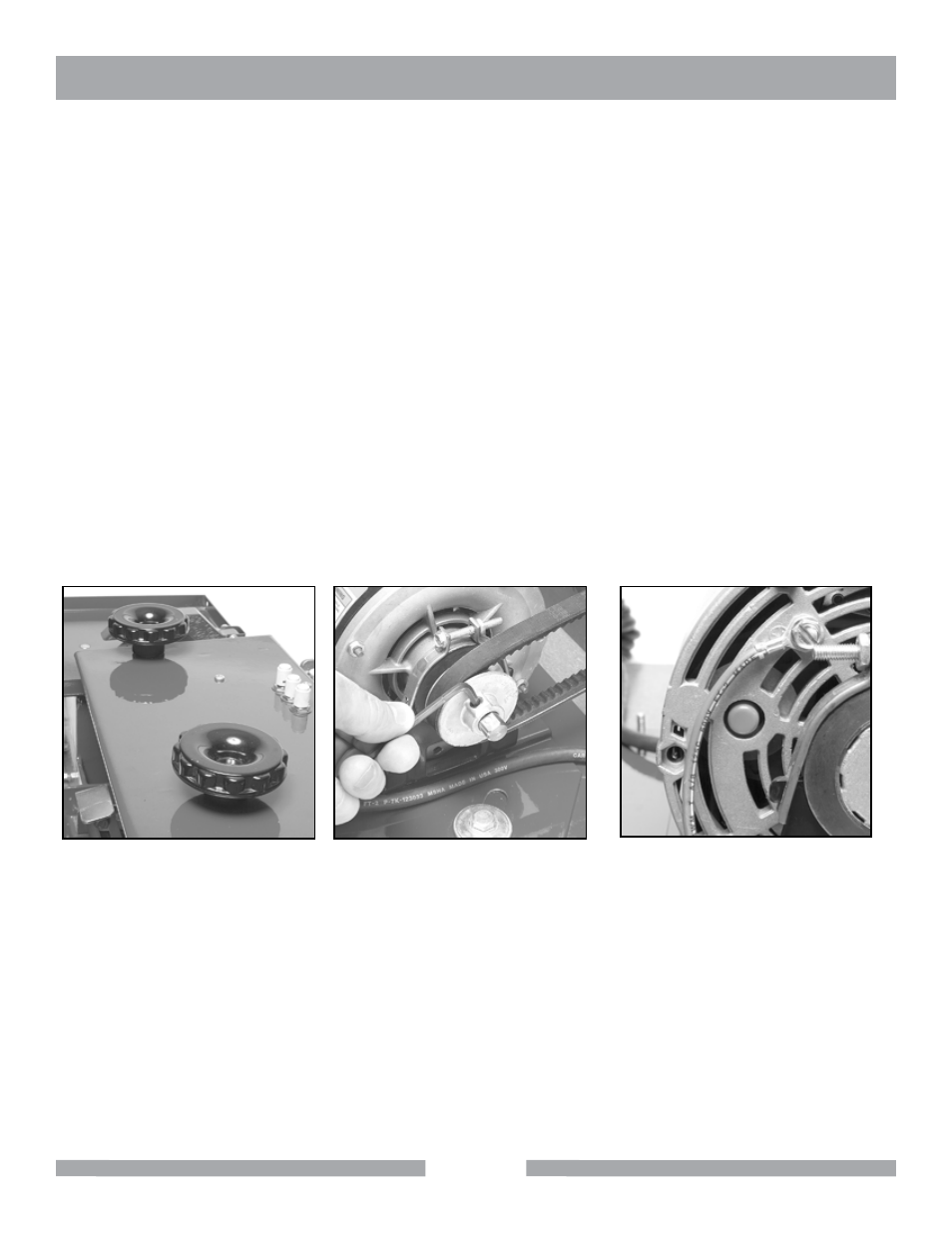

a complete unit. Periodically check the tightness of the hood attachment knobs (fig 64) to make sure

they are securely tightened to the aluminum body of the Cab Combo Workshop. Should the 2" OD die

cast pulleys on either the motor (fig 65) or blade arbor shaft need to be removed or replaced, loosen

the setscrew on the hub of each pulley with a US standard Allen type wrench. The setscrews can be

secured with liquid thread locker (removable type) to prevent loosening due to vibration.

Fig 64 - Hood attachment knobs.

Fig 65 - Motor arbor shaft pulley.

Fig 66 - Motor reset button.

CAB COMBO WORKSHOP

MAINTENANCE