Barranca Diamond CAB COMBO WORKSHOP User Manual

Page 27

27

COOLANT REPLACEMENT

The trim saw tank on the Cab Combo Workshop requires periodic routine maintenance to remove and

properly discard the build-up of rock mud, sludge and dirty lubricating fluid (oil) from the oil tank reser-

voir. It will be apparent to the user after prolonged sawing that the lubricating fluid is dirty and needs

to be changed if the oil residue on the saw table (after cutting) is thick and dark with rock sludge

build-up.

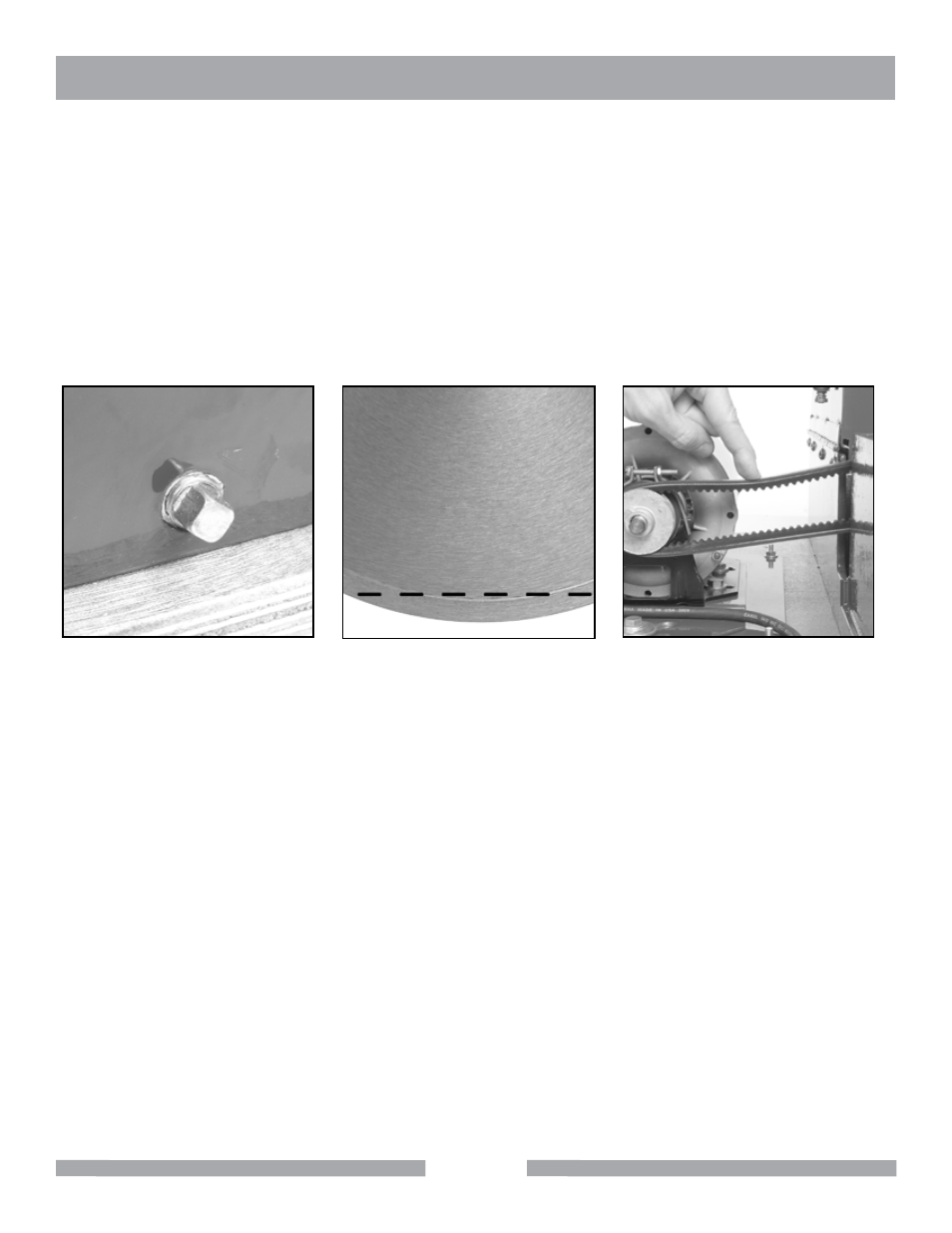

The oil liquid can be removed rapidly by removing the square-head drain plug attached to the bottom

drain hole at the base of the coolant reservoir (fig 61). The oil should be collected in a container and

either reused or properly disposed of.

Fig 61 - Drain plug

Fig 62 - Refill the cutting lubricant res-

ervoir to cover 1/4" of the bottom edge

of the blade

Fig 63 - Check belt deflection

To prevent the overflow of oil and rock sludge onto the baseboard or floor, use a bucket or collec-

tion container placed under the baseboard to allow the free flow of oil and sludge into the bucket for

proper disposal. The thicker solid sludge residue in the tank will likely not flow through the 1/4" diam-

eter drain hole. Therefore the sludge should be removed after the slab saw oil lubricant is drained, by

removing the saw tabletop and extracting the sludge with a spatula or spoon.

Once the sludge is removed, wipe the inside of the tank with disposable towels and refill the cut-

ting lubricant to cover 1/4" of the bottom edge of the blade (fig 62). The diamond blade should be

removed from the arbor shaft while removing the sludge. Be sure to check the coolant level inside of

the reservoir after every 3 to 5 hours of use as the fluid will absorb onto the rock material and will be

reduced over time due to heat and evaporation.

BELT

The Cab Combo Workshop arbor is driven from the electric motor by a AX-24 rubber belt. The Belt

tension is adjusted at the factory. However, if it is necessary to service this belt, unplug the Cab

Combo Workshop from its power source and remove the fasteners that secure the belt guard housing

to the motor. The belt tension should be checked periodically by removing the guard and depressing

the belt in the middle between both the motor and blade arbor 2" OD pulleys. There should be 1/2" of

CAB COMBO WORKSHOP

MAINTENANCE