90° sweep bend charts, Important, For conduit sizes 1 – Gardner Bender Guide to Profitable Bending User Manual

Page 27: See instructions on pages 28 - 29), First bend, Successive bends, Correcting overbends

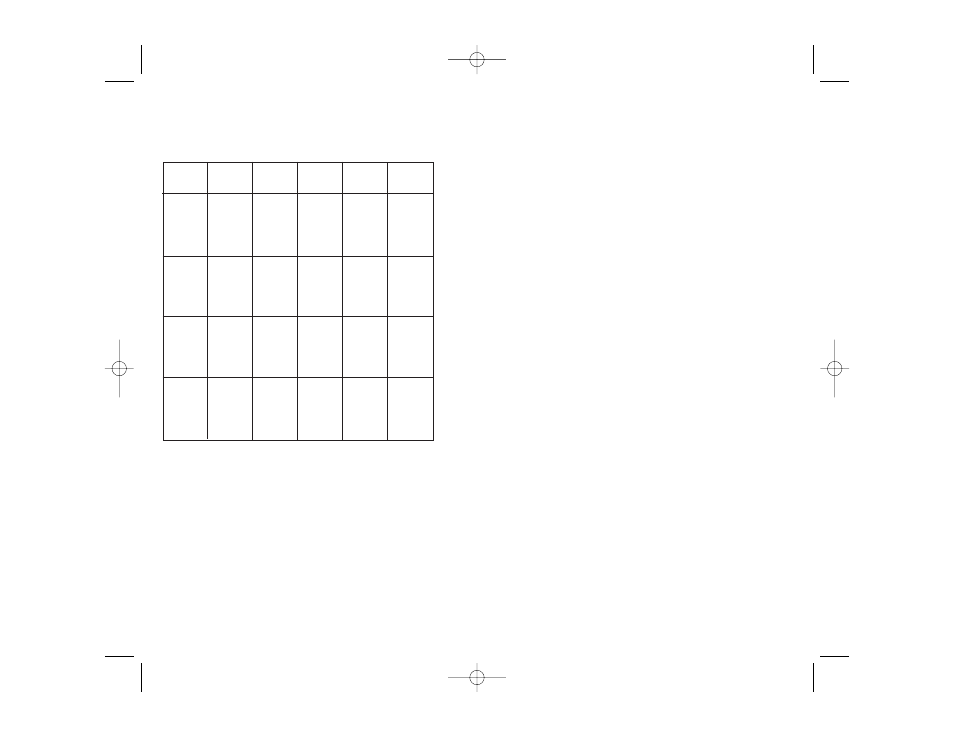

90° Sweep Bend Charts

for Conduit Sizes 1

1

⁄

4

", 1

1

⁄

2

", 2", 2

1

⁄

2

"

(See instructions on pages 28 - 29)

30

*These radii correspond to 90° one-shot bends.

For overbend corrections see pages 26-27.

Centerline (A)

(B)

(C)

Conduit

Radius

(S)

No. of

Spacing

Degree

Size

(R) (in.)

Set - back Bites (90°)

betw. Bites

per Bite

7

1

⁄

4

*

6

3

⁄

16

3

3

3

⁄

4

"

30°

9

3

⁄

4

8

43

⁄

64

4

3

7

⁄

8

"

22°

12

1

⁄

4

11

5

⁄

32

5

3

7

⁄

8

"

18°

14

3

⁄

4

13

21

⁄

32

6

3

7

⁄

8

"

15°

17

1

⁄

4

16

5

⁄

32

7

3

7

⁄

8

"

13°

8

1

⁄

2

*

7

15

⁄

64

3

4

1

⁄

2

"

30°

11

1

⁄

4

10

4

4

3

⁄

8

"

22°

14

12

3

⁄

4

5

4

3

⁄

8

"

18°

16

3

⁄

4

15

1

⁄

2

6

4

3

⁄

8

"

15°

19

1

⁄

2

18

1

⁄

4

7

4

3

⁄

8

"

13°

9

1

⁄

2

*

8

1

⁄

4

3

5"

30°

12

7

⁄

8

11

1

⁄

2

4

5"

22°

16

1

⁄

4

14

7

⁄

8

5

5

1

⁄

8

''

18°

19

5

⁄

8

18

1

⁄

4

6

5

1

⁄

8

"

15°

23

21

5

⁄

8

7

5

1

⁄

8

"

13°

10

1

⁄

2

*

9

3

⁄

16

3

5

1

⁄

2

"

30°

14

1

⁄

2

13

3

⁄

32

4

5

3

⁄

4

"

22°

18

1

⁄

2

17

1

⁄

32

5

5

3

⁄

4

"

18°

22

1

⁄

2

21

6

5

7

⁄

8

"

15°

26

1

⁄

2

25

11

⁄

32

8

5

1

⁄

4

"

11°

1

1

⁄

4

"

1

1

⁄

2

"

2"

2

1

⁄

2

"

27

Important

Before starting bend, be sure pivot pins are through bottom frame plate

and locked in position to properly anchor.

When actuating pump, either hand or electric, operator should position

himself on the cylinder side. It is not recommended that any bender be

operated from the front position.

As bend is generated, watch optic angle gauge until desired angle of

bend is reached. Because of conduit springback, it will be necassary to

go a bit beyond the desired angle.

Assemble, Bend and Eject Instructions (

see pages 18-19).

First Bend

1. Follow the same general procedure covered in Steps

A & B, pages 18 - 19).

2. Be sure to place pivot pin and pivot shoe in properly marked

hole size.

3. Do not bend beyond arc length of shoe or pipe will kink.

4. Back off shoe to release pressure on pivot shoes and proceed to

release pipe as described in Step C, pages 18 - 19.

Successive Bends

1. Depending on your sweep requirements, successive bends may be

required. After first bend, shift pivot shoe and move bent pipe as

shown, keeping unbent pipe parallel to edge of frame.

2. On bent end of pipe, pivot shoe must be shifted to any hole that will

contact pipe.

3. Proceed to repeat bends in same manner until desired sweep is

accomplished. Pipe is ejected in same manner as Step C on

pages 18-19.

Correcting Overbends

In the event of an over-bend, reverse pipe in bender frame

as shown.

1. Reposition pivot shoes and pins at overbend correction holes as

shown. Place one pivot shoe on straight end of conduit, the other at

one end of bend.

2. Be sure correct pivot shoe surfaces face the particular size conduit

you’re working on.

3. Proceed to inch bending shoe forward a few degrees at a time,

repositioning pivot shoes if necessary, until desired correction

is made.

E-507 Guide to Profitable Bending rA.qxd 10/19/09 3:17 PM Page 53